Stainless steel 1000L microbrewery equipment for beer making

Stainless steel 1000L microbrewery equipment is a complete brewing system designed to produce craft beer on a commercial scale. This equipment is specifically tailored for microbreweries, brewpubs, and small to medium-sized breweries that aim to create high-quality and unique craft beers. The 1000L capacity allows for larger batch production while maintaining the artisanal craftsmanship characteristic of microbrewing. Here are the key components and features of the stainless steel 1000L microbrewery equipment:

1. Mash/Lauter Tun: The mash/lauter tun is used to combine crushed grains with hot water for mashing, converting starches into fermentable sugars. It also serves to separate the liquid wort from the solid grain bed during lautering.

2. Brew Kettle/Whirlpool: The brew kettle is where the wort is boiled with hops and other ingredients to extract flavors and bitterness. It also doubles as a whirlpool to separate hot trub and hop residues from the wort after boiling.

3. Hot Liquor Tank (HLT): The HLT stores and heats the water needed for various brewing processes, such as mashing and sparging.

4. Fermentation Tanks: The stainless steel fermentation tanks are where the fermentation process takes place. Yeast is added to the cooled wort, converting sugars into alcohol and carbon dioxide, turning the wort into beer.

5. Glycol Cooling System: The equipment is equipped with a glycol cooling system that includes cooling jackets on the fermentation tanks. This ensures precise temperature control during fermentation for optimal beer quality.

6. Control System: The microbrewery equipment is integrated with a user-friendly control system, allowing brewers to manage and monitor temperatures and processes throughout the brewing cycle.

7. Cleaning-In-Place (CIP) System: The CIP system facilitates the cleaning and sanitation of the brewing equipment between batches, ensuring the highest standards of hygiene and quality.

8. Sight Glasses and Valves: The equipment is fitted with sight glasses and valves for easy monitoring, control, and transfer of liquids during the brewing process.

9. Safety Features: Safety measures such as pressure gauges, relief valves, and safety interlocks are included to ensure safe and reliable operation during brewing.

10. Stainless Steel Construction: The entire microbrewery equipment is constructed using high-quality stainless steel. Stainless steel is the preferred material in the brewing industry due to its durability, easy cleaning, and resistance to corrosion, ensuring a long-lasting and hygienic brewing system.

The stainless steel 1000L microbrewery equipment provides a complete and efficient solution for brewing craft beer on a commercial scale. It empowers brewers to create a wide variety of beer styles, maintain consistency, and deliver exceptional brews to their customers. With its high-quality construction and versatile capabilities, this equipment is an excellent choice for microbreweries and craft brewers seeking to expand their production capacity while preserving the artistry of craft brewing.

The equipment needed when creating a microbrewery

This is a whole setup 1000L 2-vessel micro brewing system with a hot water tank for sale,we also call it "beer cooking system"and "beer mash system".It includes

1000L Mash/Lauter tun

1000L Kettle/whirlpool tun

2000L hot water tank.

100kg/h gas steam generator

10m2 double-stage plate heat exchanger

Wort grant tank

Hop back tank

3m3/h Wort pumps

Pipes and valves

Operation platform

The 1000L microbrewery equipment is easy to operate manually

All of vessels are brushed ploshing surface,and the covers are conical type.For this brewing system for sale,client request manually control operation system,so that all of the valves are designed as manual valves,and the connectors are tri-clamps,which are more easy to operate to the brewers.As to the wort transfer of the whole system,we use sanitary centrifuge wort pump to finish it,and the pump is with VFD control(Variable Frequency Driven),in that case,you can control the wort transfer speed as you want.

The beer brewing process inside of brewhouse

The malts will be transferred to the mash tun through the grist hydrator to do the wort mashing process.The mash and wort filter process will be finished in the same tun(Mash/lauter tun),after wort filter finish,the spent grains will be removed out through the grain spent door,and the wort is pumped to the kettle/whirlpool tun.Wort will be heated inside of the kettle,and do the whirlpool to make it more clear.And the whole brewing process is finished after whirlpool.

The fermenters are included in the commercial microbrewery equipment

Here is a 1000L beer fermentation tank for sale,with 60° conical bottom,double-layer with insulation,there is dimple cooling jackets around the wall and bottom cone to give the wort a good cooling function.After brewing process finishes,the wort will be cool down and transferred to the fermentation tank. There is the place where magic happens,brewers put yeast into the fermenters to start the fermentation process,after around 20 days,a cup of flavored beer can be served!

How to control the temperature of the brewery

We can set the brewing and fermentation temperature through the PLC control cabinet,the control panel can be touched,and with a screen on the cabinet,the brewers can see the whole brewing and fermentation process more directly. Commonly,our control cabinet equippment with SIEMENS or MCGS brand touch screen,SIEMENS brand CPU,DANFOSS frequency controller and top quality electricity elements,it can make sure a stable control system for the microbrewery plant.

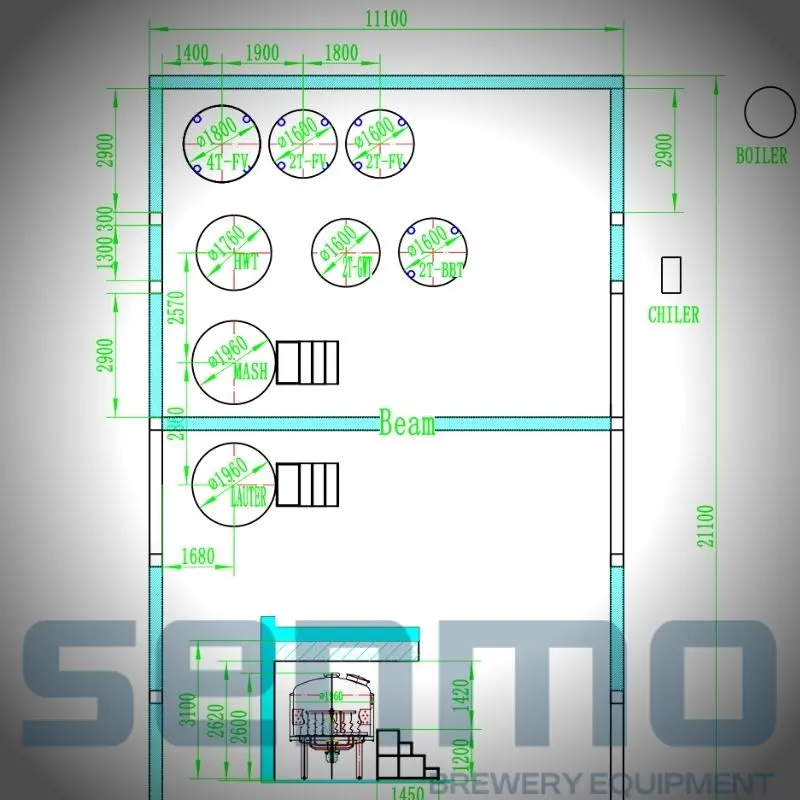

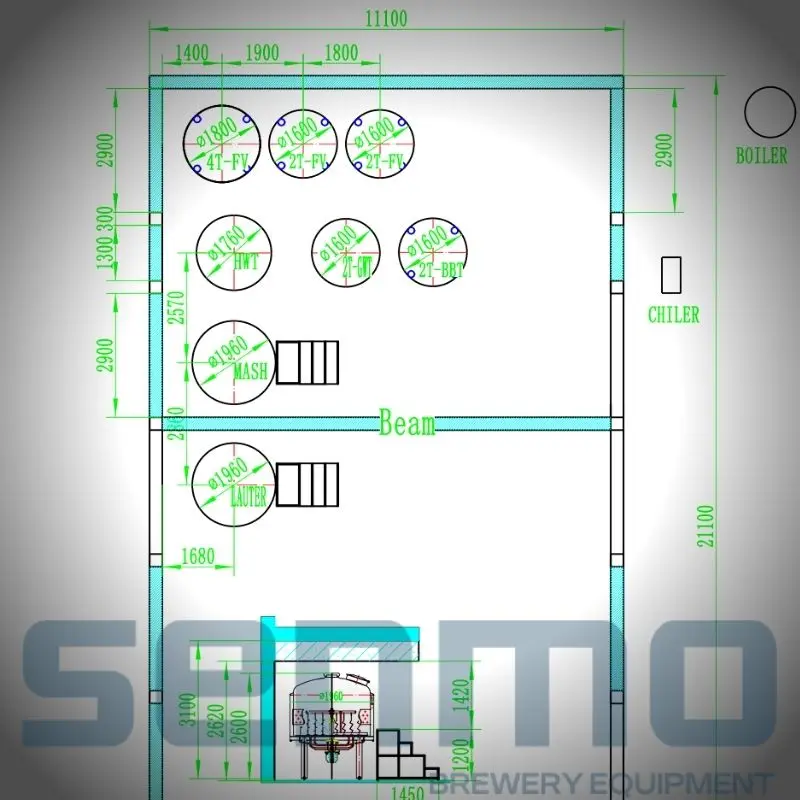

Brewery equipement layout

A detailed and free brewery layout drawing will be provided to our clients,it is designed as per the client's actual floor plan,and it is a very important step to estimate the cost of the microbrewery equipment.

What SENMO can provide for you.

Sales consulting. Provide fast, professional and detailed configuration list according to customer requirements.

Microbrewery technical design. According to the concept of customization, put forward design suggestions, integrate customer requirements, issue process flow diagrams, floor plans, containers, machinery, electrical and other drawings, draw 3D renderings, and provide one-to-one tracking services.

Processing and manufacturing. Strictly implement the requirements of beer equipment design drawings, follow the IOS9001 quality management system, strictly control the quality of all links, and provide test records of plates, welding, polishing, pressure, etc. for filing.

Delivery and installation. The professional microbrewery project construction team conducts on-site installation, commissioning and training to ensure accurate delivery for use and continuous tracking maintenance.

FAQ

Q1: What is the capacity of the Stainless steel 1000L microbrewery equipment?

A: The capacity of the Stainless steel 1000L microbrewery equipment is 1000 liters, making it suitable for small to medium-sized breweries and microbreweries producing craft beer on a commercial scale.

Q2: What components are included in the microbrewery equipment?

A: The equipment typically includes a mash/lauter tun, brew kettle/whirlpool, hot liquor tank (HLT), fermentation tanks, a glycol cooling system, a control system, and a cleaning-in-place (CIP) system for efficient and precise brewing and cleaning processes.

Q3: Is the microbrewery equipment made of stainless steel?

A: Yes, the entire microbrewery equipment is constructed using high-quality stainless steel. Stainless steel is the preferred material in the brewing industry due to its durability, ease of cleaning, and resistance to corrosion.

Q4: Can the equipment be customized to suit specific brewing needs?

A: Yes, the microbrewery equipment can be customized to meet the unique requirements and preferences of brewers. Customization options may include additional features, specific configurations, or personalized fittings.

Q5: How is the temperature controlled during fermentation?

A: The equipment is equipped with a glycol cooling system, including cooling jackets on the fermentation tanks. This system allows for precise temperature control during fermentation to ensure optimal beer quality.

Q6: Is the control system user-friendly?

A: Yes, the microbrewery equipment is integrated with a user-friendly control system, enabling brewers to manage and monitor temperatures and processes throughout the brewing cycle with ease and precision.

Q7: How is the equipment cleaned between brewing batches?

A: The microbrewery equipment is equipped with a Cleaning-In-Place (CIP) system, which facilitates the cleaning and sanitation of the brewing equipment between batches, ensuring hygiene and quality.

Q8: Is the equipment designed with safety features?

A: Yes, the equipment includes safety measures such as pressure gauges, relief valves, and safety interlocks to ensure safe and reliable operation during the brewing process.

Q9: What types of beer can be brewed with this equipment?

A: The Stainless steel 1000L microbrewery equipment allows for the production of a wide variety of beer styles, empowering brewers to experiment and craft unique brews to cater to their customers' tastes.

Q10: How can I obtain more information or request a quote for the Stainless steel 1000L microbrewery equipment?

A: For more information or to request a quote for our Stainless steel 1000L microbrewery equipment for beer making, please contact our sales team. We are dedicated to providing all the necessary details and support to help you enhance your brewing capabilities and deliver exceptional craft beer to your customers.

Q11: Is technical support provided with the Stainless steel 1000L microbrewery equipment?

A: Yes, we offer comprehensive technical support to our customers. Our team of experts is available to assist with installation, setup, and provide guidance on operating and maintaining the equipment. We are committed to ensuring a smooth brewing process and optimal performance.

Q12: Can the Stainless steel 1000L microbrewery equipment accommodate future expansion?

A: Absolutely! Our microbrewery equipment is designed with scalability in mind. If your brewery's production needs increase in the future, the equipment can be upgraded or integrated with additional tanks and features to meet your growing demands.

Q13: What kind of brewing control does the equipment offer?

A: The control system allows precise management of temperatures and various brewing parameters throughout the mashing, boiling, and fermentation stages. This level of control ensures consistent and repeatable brewing results.

Q14: Does the microbrewery equipment come with a warranty?

A: Yes, we provide a warranty for our Stainless steel 1000L microbrewery equipment to cover manufacturing defects and ensure the equipment's performance during the specified warranty period.

Q15: Can you provide installation and training services?

A: Certainly! We offer installation services and on-site training to help your brewing team become familiar with the equipment's operation and ensure a seamless integration into your brewing process.

Q16: Is the equipment suitable for producing both ales and lagers?

A: Yes, the microbrewery equipment is versatile and can produce a wide range of beer styles, including ales and lagers. Brewers can experiment and fine-tune their recipes to create diverse and high-quality beers.

Q17: What is the lead time for delivering the Stainless steel 1000L microbrewery equipment?

A: The lead time may vary based on your specific customization requirements and our production schedule. Our sales team will provide you with an estimated lead time upon request.

Q18: Can you provide references or testimonials from other breweries using your equipment?

A: Absolutely! We would be happy to provide references or testimonials from our satisfied customers who have successfully used our microbrewery equipment to brew outstanding craft beers.

Q19: Do you offer after-sales support and spare parts availability?

A: Yes, we provide comprehensive after-sales support and ensure spare parts availability for the equipment. Our team is readily available to assist with any inquiries or maintenance needs that may arise.

Q20: How can I get in touch to inquire further about the Stainless steel 1000L microbrewery equipment?

A: To inquire further, request a quote, or discuss specific details about our Stainless steel 1000L microbrewery equipment for beer making, please feel free to contact our sales team. We are dedicated to helping you achieve your brewing aspirations and deliver exceptional craft beer to beer enthusiasts worldwide.

If you plan to start a brewpub or a microbrewery,just feel free to send us your inquiry!