The complete equipment needed to brew beer commercially

The complete equipment needed to brew beer brewing commercially is generally divided into: 1. Malt crushing system. 2. Brewhouse system. 3. Fermentation system. 4. Refrigeration system. 5. CIP cleaning system. 6. Control system, 7. Filling equipment, 8. Steam, air pressure and other auxiliary systems. Below is the detailed instruction of each system.

1.Malt crushing system

The purpose of malt crushing is to better dissolve the substances in malt, the spent grians is used as the filter layer for wort filtration.

The crushing system is mainly composed of malt crusher, malt storage and feeding equipment. Small equipment can only be equipped with malt crusher. The small and medium-sized beer equipment generally equipped with the double-roller malt miller, and the large equipment is equipped with four-roller or five-roller malt miller.

2.Brewhouse system

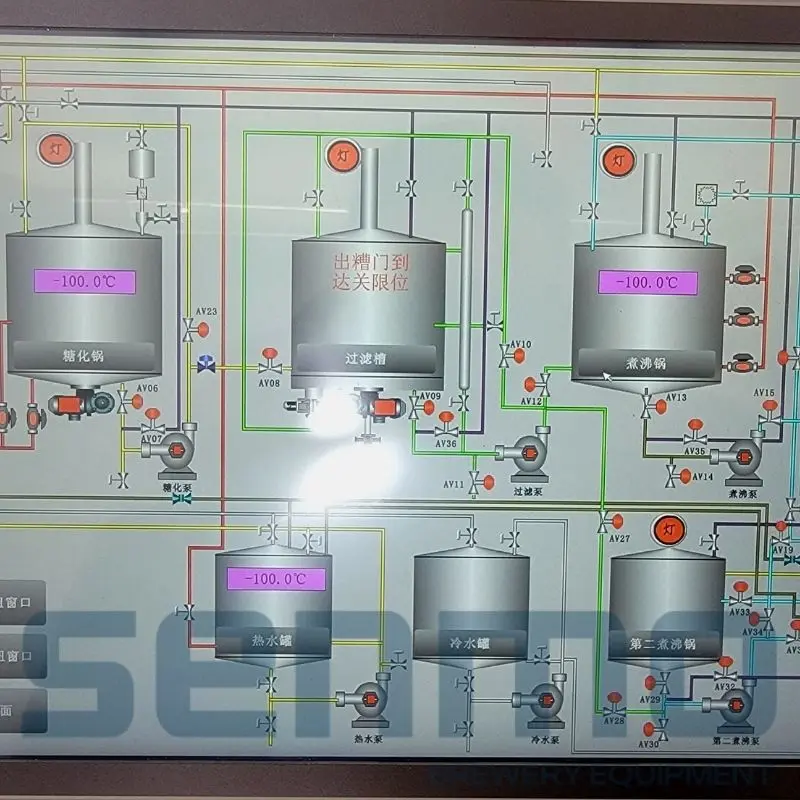

The brewhouse system is the brewing core of the whole set of equipment and the malt transferred into wort. That is, "mashing - filtration - boiling - whirlpool sedimentation". These four functional steps are completed by several tuns, which are called "#-vessel brewhouse"(#=2 or 3 or 4 or 5). The hot water tank belongs to auxiliary equipment.

The four functions are realized in three vessels, which is called "three-vessel brewhouse"(Mash tun,lauter tun,kettle/whirlpool tun). The simplest combination of brewhouse is realized by using two vessels, which is called two-vessel brewhouse (Mash/lauter tun,Kettle/whirlpool tun).

When purchasing beer equipment, the type, configuration and size of the brewhouse are determined according to the brewery site conditions, brewing process requirements and beer production batch requirements. At the same time, consider the investment cost.

"Mash - filtration - boiling - whirlpool sedimentation" is the four main process steps of wort preparation. Mash refers to the conversion of insoluble substances (starch, cellulose, part of high molecular protein, etc.) in malt into water-soluble substances (sugar, dextrin, minerals and some proteins), filtration to obtain clear wort, boiling, and whirlpool to form edible wort. The ultimate goal of the mashing is to obtain high-quality wort.After the whirlpoo, the wort should be cooled quickly. Yeast can only reproduce at low temperature and cool the wort to the fermentation temperature required by the process. Make the wort temperature meet the requirements of yeast inoculation.(The lower fermentation should be cooled to 6 ℃ - 9 ℃, and the upper fermentation should be 12 ℃ - 20 ℃).After the wort is cooled, the wort is oxygenated. Only after the yeast absorbs sufficient oxygen can it synthesize the substances needed for its reproduction. Add yeast after oxygenation.

3.Fermentation system

The fermentation system is mainly composed of fermentation tanks. Wort is fermented into beer in a fermentor. The fermentation tank has cooling and insulation functions. From the inside to the outside of the fermentation tank, there are: inner liner, cooling jacket, insulation layer and outer skin. The control system controls the temperature of beer in the fermentation tank according to the temperature set for fermentation. The coolant of the refrigeration system is the cooling medium.

4.Refrigeration system

The main function of the refrigeration system is to provide a cold source for the cooling of wort after whirlpool and beer fermentation. The main equipment consists of: Glycol water tank (adding 30% of the tank volume of ethylene glycol or edible alcohol to ensure that there is no freezing at minus 6 ℃), cold water tank (large equipment and many batches of brewing need to be equipped, small equipment can not be used), and chiller.

5.CIP system

Breweries generally use the Cleaning In Place (CIP) method to clean and sterilize the equipment, that is, the process of cleaning and disinfecting the equipment without removing the equipment parts or pipe fittings in a closed environment.

The larger the beer equipment, the higher the requirements for cleaning the equipment. Configure CIP equipment according to equipment size and requirements.

6.Control system

It mainly refers to the electronic control, semi-automatic and automatic control of each system. Control of brewhouse system, fermentation system, refrigeration system, etc. The control of small equipment is relatively simple and the price is relatively cheap. Large equipment and equipment have high control requirements, high automation level and complexity, and high cost.

7.Filling system

The filling equipment mainly refers to the packaging of the mature liquor after beer fermentation.There are glass bottle filling machine, barrel filling machine and barrel washing machine; Bottle filling machine and can filling equipment with high automation. As well as filtration equipment, sterilization equipment (commonly used sterilization equipment: Flash pasteurizer, Tunnel pasteurizer, sterilization kettle), packaging equipment, etc.

8.Auxiliary equipment

Auxiliary equipment generally refers to the steam boiler,water treatment equipment for brewing water,air compress system and other supporting equipment.

Above is all items needed for brewing in minecraft,as a professional beer equipment manufacturer,SENMO always dadicate to give the most complete and functional brewing equipment to our clients with lower investment from them. If you have interest in the beer brewery equipment and want to know details cost,please contact with us,we have sales engineers who can give you the formal quotation.