Microbrewery 300L temperature controlled fermenter

What is temperature controlled fermenter?

A temperature-controlled fermenter, also known as a fermentation vessel or fermenting tank, is a specialized container used in the beer brewing and winemaking processes to facilitate controlled fermentation. It is a crucial piece of equipment that provides an optimal environment for yeast or other microorganisms to convert sugars into alcohol and carbon dioxide, transforming wort into beer or grape juice into wine.

Key Features of a Temperature-Controlled Fermenter:

Insulation: Temperature-controlled fermenters are typically equipped with insulation to maintain a stable internal temperature during the fermentation process. This helps to prevent temperature fluctuations that could adversely affect the fermentation outcome.

Cooling and Heating Systems: Advanced temperature-controlled fermenters are equipped with cooling and/or heating systems to regulate the internal temperature. Cooling is crucial to keep the fermentation process from getting too hot, while heating is useful in colder environments or for certain styles of beer that require higher fermentation temperatures.

Thermowell and Temperature Probe: A thermowell is a tube inserted into the fermenter to house a temperature probe. The temperature probe measures the internal temperature of the fermenting liquid, providing real-time feedback to the temperature control system.

Digital Control Panel: A digital control panel allows brewers or winemakers to set and monitor the desired fermentation temperature. The control panel interacts with the cooling and heating systems to maintain a consistent and precise temperature throughout the fermentation process.

Benefits of Using a Temperature-Controlled Fermenter:

Consistency: Controlling the fermentation temperature ensures consistency in the fermentation process and the final product. This is crucial for producing high-quality and reproducible beer or wine batches.

Yeast Health and Performance: Yeast is sensitive to temperature fluctuations, and maintaining a stable fermentation temperature promotes healthy yeast activity and optimal fermentation performance.

Off-Flavor Reduction: Temperature control helps to minimize the production of undesirable off-flavors during fermentation, resulting in a cleaner and more balanced beer or wine.

Wider Range of Beer Styles: With temperature control, brewers can ferment a wide range of beer styles that require specific temperature profiles, including ales, lagers, and specialty brews.

Applications:

Temperature-controlled fermenters are essential in commercial breweries, craft breweries, wineries, and home brewing setups. They are used for a variety of fermentation processes, such as primary fermentation, secondary fermentation, and aging.

In summary, a temperature-controlled fermenter is a crucial tool for brewers and winemakers seeking precise control over the fermentation process. By providing the ideal environment for yeast activity, this specialized equipment plays a significant role in achieving consistent and high-quality results in the production of beer and wine.

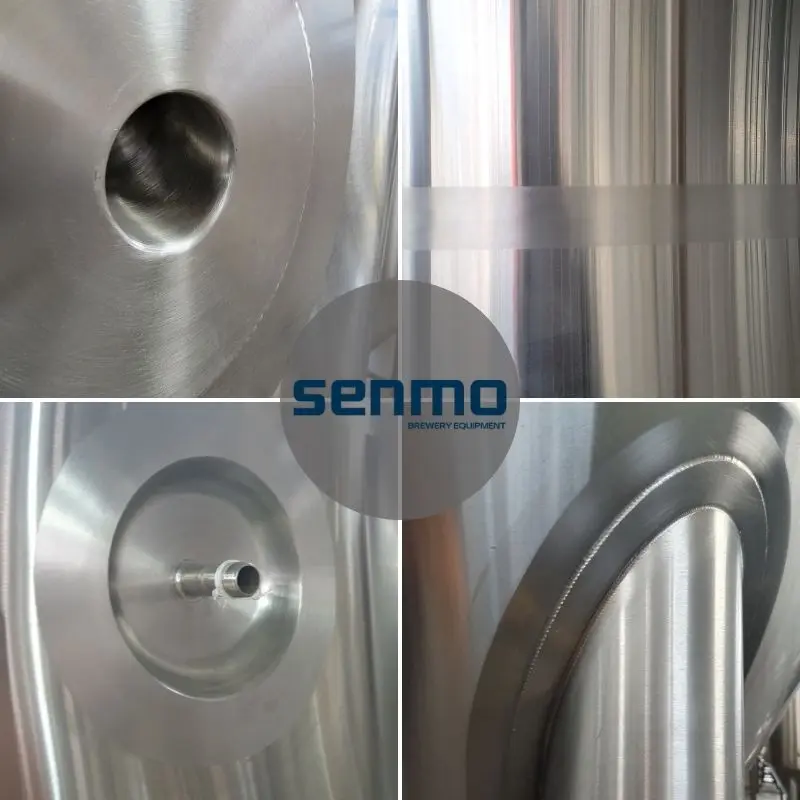

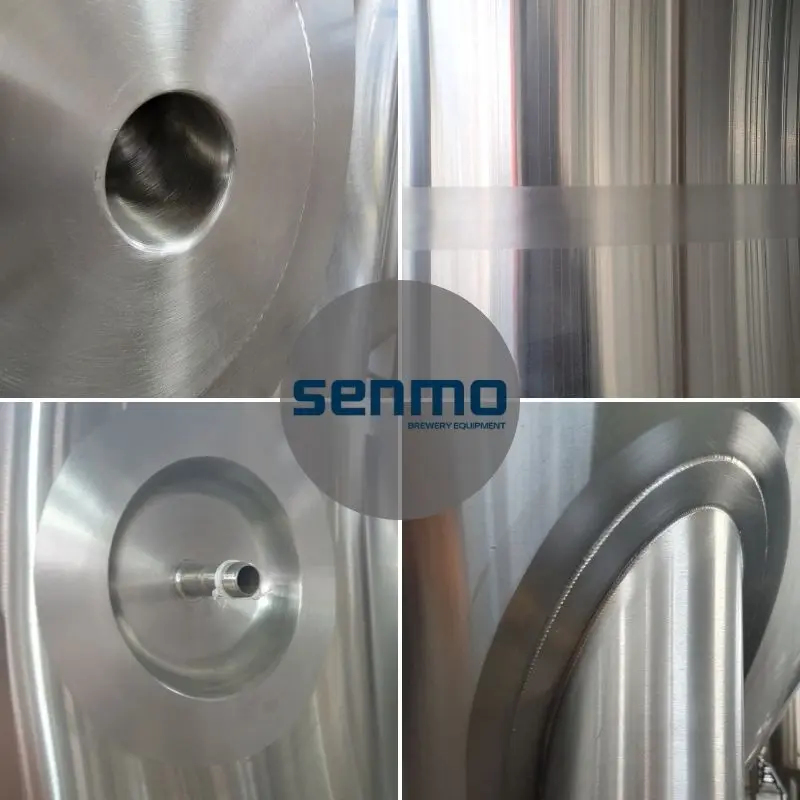

The 300L beer fermenters made by SUS304 sanitary plate.It is double walls with insulation,the dimple jackets around the inner wall and bottom cone.There is temperature sensor and transmitter on the cone to control the beer temperature. The cooling water inlet and outlet are designed on the one,which can save much space between the tanks and wall.

The shorter diameter makes the tanks save much floor area,especially when your brewery space is small,this design can be good for that.

We focus more on the equipment details design,such as the welding,polishing..The 300l temperature controlled fermenters pipe fittings support DIN, ISO, SMS and other customized standards.The tanks top is stainless steel dished head, fermenters are lower 60 ° cone bottom,bright beer tanks are with dished bottom; The tanks manway can be on top or side of the fermenters. The cooling pipe connection can also be customized produce,you can choose tri-clamp connection,thread connection,diary coupler connection or other way you want.

The tanks will be equipped with a complete set of fittings,see the below list

Pressure regulating valve

Breath valve to adjust the positive and negitive of the pressure

Beer racking arm

Drain outlet with butterfly valve

Beer sample valve

CO2 charging device

Temperature sensor blind tube

Hops dosing port

CIP arm and CIP ball

Our factory use laser cutting and argon shielded welding during the tanks' production, the internal of the tanks commonly do pickling and passivation, the surface accuracy ≤ 0.4 μ m;The fermenters and bright tank has polyurethane foam insulation,thickness is 80mm;There is dimple cooling jackets around the tank body and bottom cone,the test pressure is 0.4MPa; The working pressure of the tank is 0.15 MPa, and the test pressure is 0.4 MPa; Our factory do water pressure test to all of the fermenters and bright tanks,the test period is 48hours.The strictly test and inspection make sure the tanks inside,the dimple jackets and pipe ports has no leakage when the fermenters arrives in our clients' brewery.

The price of the 300l temperature controlled fermenter is different because of various configuration.If you want add extra beer fermenters inside of your brewery,please send us your requirements on it,such as the quantity of the fermenters,the fittings on the fermenters,your brewery layout drawings...our sales engineer can send you a formal 300l beer fermenter quote for reference.

FAQ

Q1: What is the capacity of the microbrewery 300L temperature-controlled fermenter?

A: The microbrewery 300L temperature-controlled fermenter has a capacity of 300 liters, making it suitable for small to medium-scale brewing operations.

Q2: Is the temperature control system fully integrated into the fermenter?

A: Yes, the temperature control system is fully integrated into the microbrewery 300L fermenter. It includes cooling and/or heating capabilities to maintain a stable and precise fermentation temperature.

Q3: How does the temperature control system work in the fermenter?

A: The temperature control system utilizes a digital control panel, thermowell, and temperature probe. The control panel allows the brewer to set and monitor the desired fermentation temperature, while the thermowell houses the temperature probe, which provides real-time feedback to the control system.

Q4: Can the fermenter accommodate a variety of beer styles with different fermentation temperature requirements?

A: Yes, the microbrewery 300L temperature-controlled fermenter is versatile and can accommodate a wide range of beer styles, including ales and lagers, which may have different temperature profiles for fermentation.

Q5: What are the benefits of using the microbrewery 300L temperature-controlled fermenter?

A: The microbrewery 300L temperature-controlled fermenter offers benefits such as precise fermentation temperature control, consistent and reproducible brewing results, improved yeast performance, and reduced risk of off-flavors in the final beer.

Q6: Is the fermenter suitable for commercial microbreweries or home brewing setups?

A: The microbrewery 300L temperature-controlled fermenter is ideal for both commercial microbreweries and enthusiastic home brewers looking to produce small to medium-sized batches of beer.

Q7: Does the fermenter come with insulation to maintain a stable temperature?

A: Yes, the microbrewery 300L temperature-controlled fermenter is typically equipped with insulation to maintain a stable internal temperature during fermentation.

Q8: Can I use the fermenter for both primary and secondary fermentation?

A: Yes, the microbrewery 300L temperature-controlled fermenter can be used for both primary and secondary fermentation, as well as for aging beer if desired.

Q9: Is technical support provided for the installation and operation of the fermenter?

A: Reputable manufacturers of the microbrewery 300L temperature-controlled fermenter often provide technical support, including installation guidance and operational training, to ensure brewers can use the equipment effectively.

Q10: How can I get more information and place an order for the microbrewery 300L temperature-controlled fermenter?

A: For more information and to place an order for the microbrewery 300L temperature-controlled fermenter, please contact our sales team. They will be happy to assist you with all the details and guide you through the ordering process. Cheers to your brewing success with the microbrewery 300L temperature-controlled fermenter!