10bbl small beer production line for microbrewery

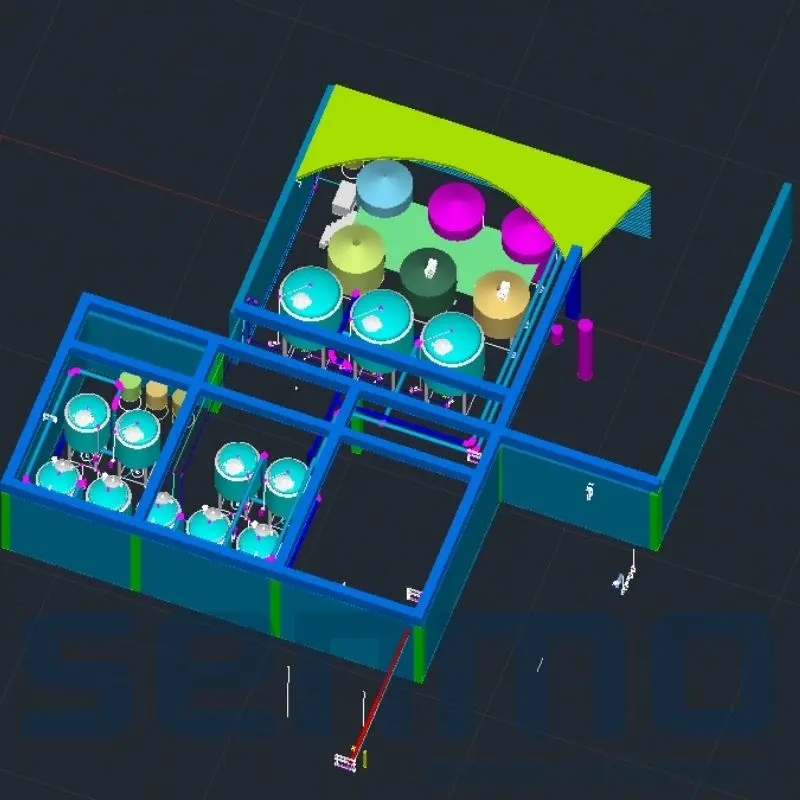

The 10bbl small beer production line for microbrewery consists of a 10bbl beer brewing system, a 10bbl beer fermentation system, an auxiliary system, a beer filtration system, a beer refrigeration system,and control system. The microbrewery 10bbl beer equipment is advanced in design and manufacturing, and the entire process can achieve semi-automatic or fully automatic control.Below is the general brewing equipment list of the 10bbl small beer production line for microbreweries.

Malt milling system,includes malt miller,auger and grist case

10bbl brewing system,includes 10bbl mash tun,10bbl lauter tun,10bbl kettle,the heating way can be steam heating,fire directly heating or electric tubes heating.

10bbl fermentation system,inclides 10bbl fermenters, hops adding device,hop gun,10bbl brigte tank

Cooling system,includes glycol water tank,chiller,cooling pipes and valves

CIP cleaning system,includes alkali water tank,acid water tank,CIP trolley

Control system,PID or PLC control

10bbl brewery auxiliary system,includes steam generator,air compressor,beer filter....

The design of microbrewery small beer production line details is rigorous, so as to maximize the utilization of brewing materials and reduce equipment energy consumption.The brewhouse tank plates and accessories are made of international standard SUS304 stainless steel; Our factory use laser cutting and argon shielded welding during the tank production,all vessels' internal do centralized pickling and passivation, accuracy ≤ 0.4 μ m;

This set of 10bbl small beer production line for microbreweries has comprehensive system configuration, advanced equipment performance, flexible operation, safety and stability, and can fully meet the requirements of scientific research and practical training. Here are some characteristics of microbrewery 10bbl small beer production line:

Strong operability: The configuration of the entire set of small beer production line and the design of the beer production process are simillar to those of large breweries, and the operability is very strong;

Fully transparent design: allows users to understand the entire structure of the microbrewery beer production line, allowing you to grasp every physical and chemical detail change in the beer production process at any time;

Automatic and manual switching: Independent research and development has applied PLC touch screen automatic control to the system, not only realizing automatic attendance of the unmanned system, but also allowing automatic and manual switching.

Universal function: This small beer production line for microbrewery can not only produce a variety of beer, but also produce various biological fermentation products such as whisky, gin, etc. by changing the process conditions.

All 10bbl small beer production line and work will be in compliance with the following norms and standards.

•Machinery Directive 2006/42/EC According to harmonized standard EN ISO 12100:2010

•Low Voltage Directive 2014/35/EU

•Health and Safety requirements of the Directive 2006/42/EC

All material in contact with product will be of Stainless Steel,304.Light glass made of glass.

Pipe/Fitting standard will be designed according to your request

All valves in contact with product will be of Hygienic Butter Valve Type

All components and wire will be with CE marked

Process connections will be designed according to your request.Sanitary screw couplings or Sanitary Tri-clamp

Welds will be fully burned,shield gas will be used.With no pores,cracks.

In the world of craft beer, small is often synonymous with quality, innovation, and the freedom to experiment. Our 10BBL Small Beer Production Line for Microbrewery is not just a product; it's an invitation to embark on a journey of brewing excellence. Let's explore the reasons why you should consider our top-of-the-line system for your microbrewery:

1. Masterful Craftsmanship

Craft beer is an art form, and our 10BBL production line is your palette. With meticulous attention to detail, we've engineered a system that empowers you to craft beer with precision and finesse. It's the tool you need to turn your brewing dreams into liquid reality.

2. Scalable Brewing Capacity

Our 10BBL system offers the perfect balance between small-scale brewing and production capability. It's ideal for microbreweries looking to meet increasing demand without compromising on the quality that defines their brand.

3. Versatile Brewing Capabilities

The brewing world is all about innovation, and our production line is designed to accommodate your creativity. Experiment with different beer styles, ingredients, and recipes, knowing that our system's flexibility can bring your vision to life.

4. Quality Assurance

Craft beer enthusiasts are discerning customers, and they expect quality above all else. Our production line ensures consistent quality across batches, building trust in your brand and earning you loyal patrons.

5. Compact Footprint

Space efficiency is vital for microbreweries, and our 10BBL system is thoughtfully designed to maximize your available area. This allows you to allocate your space not just for brewing but also for a welcoming taproom or other essential brewery components.

6. Streamlined Operations

With an emphasis on efficiency and ease of use, our production line streamlines your brewing process. This results in reduced labor, simplified cleaning, and a smoother workflow, translating to cost savings and productivity gains.

7. Sustainable Brewing

Craft beer aficionados often appreciate sustainability. Our production line is designed with resource efficiency in mind, helping you minimize your brewery's environmental footprint while gaining the approval of eco-conscious consumers.

8. Built for the Future

In the world of brewing, adaptability is key. Our 10BBL production line is built to support your growth. As your microbrewery expands, you can rely on the scalability of our system to keep pace with your ambitions.

9. Expert Support

Behind every great system is a team of experts. We provide not just a product but the support and guidance you need to unleash the full potential of your microbrewery.

10. Brewing Excellence

Our 10BBL Small Beer Production Line for Microbrewery is more than equipment; it's your ticket to brewing excellence. It empowers you to craft beer with artistry, meet growing demand, and secure your place in the craft beer movement. Your brewery is more than a business; it's a passion, a dream, and a mission to craft the finest beer possible. Let our production line be your trusted partner on this remarkable journey. Contact us today and embrace the art of craft beer brewing.

As a professional beer equipment manufacturer,SENMO always dadicate to give the most complete and functional brewing equipment to our clients with lower investment from them. If you have interest in opening a microbrewery and want to buy a set of 10BBL small beer production line,please contact with us,we have sales engineers who can give you the formal quotation.We provide you with professional brewing technical consultation in the early stage, and carries out beer equipment design, production, installation, commissioning and other services according to the requirements of beer brewing technology.

FAQ

1. What is a 10BBL small beer production line for a microbrewery, and how does it work?

A 10BBL production line is a specialized brewing system designed for microbreweries. It includes all the necessary equipment for mashing, boiling, fermenting, and conditioning beer. The line works by taking raw ingredients, processing them through various stages, and producing finished beer.

2. What are the key components of a 10BBL small beer production line?

A typical 10BBL production line includes a mash tun, kettle, fermentation tanks, and a conditioning tank. It may also have pumps, heat exchangers, and a control panel for managing the brewing process.

3. What is the brewing capacity of a 10BBL production line, and is it suitable for a microbrewery?

A 10BBL production line has a capacity of 10 barrels or approximately 310 gallons. It's an ideal choice for a microbrewery, offering a balance between small-scale production and the capability to meet growing demand.

4. Can I brew different styles of beer with a 10BBL production line?

Yes, a 10BBL production line is versatile and can be used to brew a wide range of beer styles. The system's flexibility allows you to experiment with various recipes and ingredients.

5. What is the footprint of a 10BBL production line, and how can it fit into a microbrewery space?

The footprint of a 10BBL production line can vary, but it's designed to be space-efficient. The components are typically organized to maximize the use of available space in a microbrewery.

6. How do I maintain and clean a 10BBL production line, and what support is provided?

Regular cleaning and maintenance are essential for optimal operation. We offer maintenance guidelines and technical support to ensure your production line operates smoothly.

7. Can I expand the brewing capacity of my microbrewery with a 10BBL production line in the future?

Yes, a 10BBL production line is scalable, and it can support your microbrewery's growth. As your demand increases, you can expand your production capacity by adding additional fermenters or tanks.

8. Is this production line suitable for sustainable brewing practices?

Yes, many components of a 10BBL production line are designed with resource efficiency in mind, allowing for sustainable brewing practices and reducing the environmental impact.

9. How can I purchase a 10BBL small beer production line for my microbrewery?

You can contact our sales team to inquire about purchasing a 10BBL production line for your microbrewery. We'll provide you with details on pricing, customization options, and delivery information.

10. What are the key benefits of using a 10BBL small beer production line for a microbrewery?

The key benefits include scalability, versatility for brewing different styles, consistent quality, efficient use of space, streamlined operations, sustainability, and the potential for future expansion.