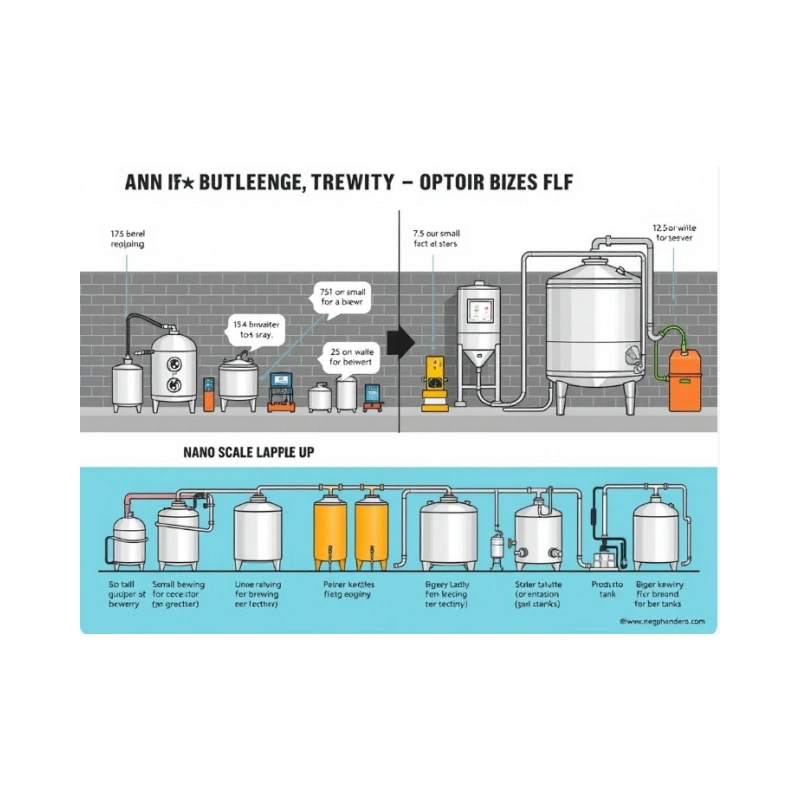

The craft brewing industry thrives on growth, and for many nano-breweries (typically producing 1-3 barrel batches), scaling up to a 15 BBL brewhouse represents a critical milestone. A nano brewery often operates as a small-batch, experimental, or local-focused business, while a 15 BBL system significantly increases production capacity—allowing for greater market reach, improved efficiency, and enhanced profitability. However, this transition requires careful planning, investment, and operational adjustments to succeed.

So, why scale up? The primary drivers include meeting rising demand (especially if your nano batches sell out quickly), reducing per-unit costs (larger batches mean better economies of scale), and expanding distribution (entering new markets or securing taproom stability). A 15 BBL brewery can produce 465-gallon batches—enough to supply local bars, restaurants, and retailers while maintaining room for growth. Additionally, automation features in larger systems can streamline brewing processes, reducing labor intensity and improving consistency.

Yet, the shift isn’t without challenges. High upfront costs (equipment, facility upgrades, licensing), logistical hurdles (larger ingredient orders, storage needs), and operational complexity (staff training, quality control at scale) must be addressed. There’s also the risk of overextending if demand doesn’t materialize as projected. However, the rewards—increased revenue, stronger brand presence, and long-term sustainability—make scaling a compelling move for brewers ready to grow.

In this guide, we’ll walk through the essential steps—from assessing feasibility and selecting equipment to refining recipes and expanding distribution—to help you navigate the transition from nano to 15 BBL brewing successfully.

Pre-Scale-Up Assessment: Is Your Brewery Ready for 15 BBL Production?

Before making the leap from a nano to a 15 BBL brewery, a thorough pre-scale-up assessment is crucial. This phase ensures that your business can sustainably support increased production while avoiding costly mistakes. Key areas to evaluate include market demand, financial readiness, and facility requirements—each playing a vital role in a successful transition.

1. Market Demand: Can You Sell More Beer?

Scaling to 15 BBL means brewing 5–10x more beer per batch, so you must confirm that local or regional demand justifies the increase. Start by analyzing:

Current Sales Trends: Are your nano batches consistently selling out? Do retailers or distributors request larger quantities?

Competition & Gaps: Is there underserved demand in your area for your beer style or brand?

Distribution Channels: Can you expand into new markets (e.g., regional bars, grocery stores) or ramp up taproom sales?

Seasonal Fluctuations: Will production align with peak demand periods (e.g., summer, holidays)?

Conduct surveys, talk to buyers, and test limited batch expansions before committing. Overestimating demand can lead to wasted beer and cash flow problems.

2. Financial Readiness: Can You Afford the Investment?

A 15 BBL brewhouse requires significant capital. Budget for:

Equipment Costs: $250,000–$500,000+ for a new 15 BBL system (fermenters, glycol chillers, packaging lines).

Facility Upgrades: Leasing or renovating a larger space ($50,000–$200,000+ depending on location).

Licensing & Compliance: Federal (TTB), state, and local permits may have higher fees at this scale.

Working Capital: Larger ingredient orders, payroll for additional staff, and marketing.

Create a detailed ROI projection—how long until the increased production pays off? Most breweries see returns in 2–4 years if sales grow as planned. Explore funding options like small-business loans, investors, or equipment leasing.

3. Facility Requirements: Do You Have the Right Space?

A 15 BBL system needs at least 3,000–5,000 sq. ft. (vs. 1,000–2,000 sq. ft. for nano setups). Key considerations:

Layout Efficiency: Separate zones for brewing, fermentation, packaging, and storage to avoid bottlenecks.

Utility Upgrades:

Water: 15 BBL batches may require 10x more water (including cooling/heating and cleaning).

Electrical: High-voltage systems (e.g., 200-amp service) for electric brewhouses.

Drainage: Floor trenches and proper slope for CIP (clean-in-place) wastewater.

Ceiling Height & Load-Bearing: Fermenters can weigh thousands of pounds when full.

Visit other 15 BBL breweries for inspiration, and consult contractors early to avoid costly retrofits.

Scaling up is a major commitment, but with the right planning, it can transform your brewery’s future. Next, we’ll dive into equipment selection—the heart of your 15 BBL operation.

Equipment Upgrades & Considerations for Scaling to a 15 BBL Brewery

Transitioning from a nano (1-3 BBL) to a 15 BBL brewery requires significant equipment upgrades to handle larger batch sizes efficiently. This section covers brewhouse selection, fermentation capacity, ancillary systems, and new vs. used equipment trade-offs—with data-driven insights to guide your investment.

1. Brewhouse: Key Differences Between Nano and 15 BBL Systems

A 15 BBL brewhouse introduces automation, higher efficiency, and different heating methods compared to nano setups.

| Feature | Nano (1-3 BBL) | 15 BBL System | Considerations |

|---|---|---|---|

| Automation | Mostly manual | Programmable controllers (PLCs) for mashing/sparging | Reduces labor but increases upfront cost |

| Heating Method | Electric or direct-fire | Steam or high-power electric | Steam is more efficient but requires boilers |

| Batch Time | 6-8 hours | 8-10 hours (larger volumes take longer to heat/cool) | Scheduling impacts production capacity |

| Efficiency | ~70-75% (lower due to manual processes) | 80-85% (better lautering, recirculation) | Higher yield = more beer per batch |

Recommendation: If budget allows, opt for semi-automated steam systems—they offer the best balance of speed and consistency.

2. Fermentation & Brite Tanks: Matching Capacity

A 15 BBL brewhouse needs larger fermentation vessels (FV) and brite tanks (BT) to maintain production flow.

| Tank Type | Recommended Size | Purpose | Typical Quantity Needed |

|---|---|---|---|

| Primary Fermenters | 30 BBL (for single batches) | Primary fermentation (7-14 days) | 2-3 (for pipeline continuity) |

| Secondary/Brite Tanks | 15-30 BBL | Carbonation, conditioning, serving | 2-4 (depending on packaging needs) |

| Unitanks | 30-60 BBL (for double batches) | Combines fermentation & serving | Saves space but higher cost |

Key Tip: If brewing double batches (30 BBL), ensure your glycol chiller can handle the increased cooling load.

3. Ancillary Equipment: Scaling Support Systems

Beyond the brewhouse, additional upgrades are necessary:

| Equipment | Nano Scale | 15 BBL Requirements | Cost Estimate |

|---|---|---|---|

| Pumps | Small, manual | Larger sanitary pumps (3-5 HP) | $1,500–$5,000 |

| Glycol Chiller | 1-2 HP | 5-10 HP (for multiple tanks) | $10,000–$30,000 |

| Grain Handling | Manual milling | Automated auger or silo system | $5,000–$20,000 |

| Packaging Line | Manual canning/bottling | Semi-auto canning (~15 CPM) | $50,000–$150,000 |

Critical Note: A proper CIP (Clean-in-Place) system is essential—manual cleaning at this scale is impractical.

4. New vs. Used Equipment: Pros, Cons & Sourcing Tips

| Factor | New Equipment | Used Equipment |

|---|---|---|

| Cost | High ($300K–$600K for full setup) | 30-50% cheaper ($150K–$350K) |

| Warranty | Full manufacturer coverage | Limited or none (inspect thoroughly) |

| Lead Time | 6-12 months (custom builds) | Immediate availability (if in stock) |

| Lifespan | 15-20+ years | 5-10 years (depending on prior use) |

| Customization | Tailored to your needs | Fixed specs (may need modifications) |

Where to Buy Used?

ProBrewer.com (industry marketplace)

Brewery auctions (closed businesses)

Equipment brokers (specialized resellers)

Recommendation: If budget is tight, prioritize used fermenters and brite tanks (durable) but invest in a new brewhouse (critical for consistency).

Scaling to 15 BBL requires matching equipment to production goals while balancing cost and efficiency. Next, we’ll discuss recipe scaling and process adjustments to maintain quality at larger volumes.

Brewing Process Adjustments for a 15 BBL Brewery

Scaling up from a nano to a 15 BBL system requires more than just bigger equipment—it demands recipe refinements, optimized scheduling, and stricter quality control to maintain consistency and efficiency.

1. Recipe Scaling: Avoiding Off-Flavors

Larger batches behave differently, so adjustments are crucial:

Hop Utilization:

Bittering Hops: Scale linearly (e.g., 1 oz/BBL → 15 oz for 15 BBL).

Aroma Hops: May need 10-20% more due to reduced surface-area-to-volume ratio in larger kettles.

Mash Efficiency:

Expect 5-10% higher efficiency (better grain hydration, recirculation).

Adjust grain bills to avoid overly high OG (original gravity).

Yeast Pitching Rates:

Use pitching calculators (e.g., 1 million cells/mL/°P).

Over-pitching can cause yeast stress; under-pitching leads to stalled fermentation.

Pro Tip: Test scaled recipes in small pilot batches before full production.

2. Batch Scheduling: Maximizing Throughput

A 15 BBL system’s ROI depends on keeping tanks full and turnover high:

Staggered Fermentation:

Brew 2-3 times/week to keep fermenters active (e.g., Monday/Wednesday brewing).

Use unitanks to combine fermentation and conditioning, saving tank space.

Double Batching:

Brew back-to-back 15 BBL batches into a 30 BBL fermenter (requires larger HLT/MLT).

Packaging Overlap:

Schedule canning/bottling while fermenting next batch to minimize downtime.

Key Metric: Aim for 6-8 turns per fermenter per year for profitability.

3. Quality Control: Lab Tools & SOPs

At 15 BBL, small flaws multiply fast, so invest in:

| Tool | Purpose | Cost |

|---|---|---|

| Microscope + Hemocytometer | Yeast cell counting/vitality | $500–$2,000 |

| DO (Dissolved Oxygen) Meter | Prevents oxidation in packaging | $1,500–$5,000 |

| pH Meter | Ensures mash/beer consistency | $200–$1,000 |

| Forced Ferment Test | Checks final gravity stability | Low-cost |

SOPs (Standard Operating Procedures) to Implement:

Yeast Harvesting: Reuse yeast ≤5 generations to avoid mutations.

CIP Cycles: Document cleaning times/temps for each tank.

Sensory Panels: Train staff to detect off-flavors early.

Key Takeaway

Scaling recipes, optimizing scheduling, and tightening QC are non-negotiable for 15 BBL success. Next, we’ll cover staffing and workflow changes to match your new production scale.

Operational & Labor Changes for a 15 BBL Brewery

Scaling to 15 BBL production requires strategic staffing, workflow automation, and updated compliance measures to handle increased demand efficiently.

1. Staffing Needs: Building Your Team

Transitioning from nano to 15 BBL means more hands on deck:

Head Brewer – Oversees production, recipe development, and QC.

Cellar Workers (1-2) – Manages fermentation, transfers, and CIP.

Packaging Line Operators – Handles canning/bottling (semi-automated systems still need labor).

Sales & Distribution Staff – Expands market reach via taproom, wholesale, or e-commerce.

Tip: Cross-train staff for flexibility during peak production.

2. Workflow Efficiency: Automating Repetitive Tasks

Reduce manual labor with:

CIP (Clean-in-Place) Systems – Cuts tank cleaning time by 50%+ vs. manual scrubbing.

Grain Handling Automation – Augers or silos speed up milling/mashing.

Packaging Line Integration – Semi-auto fillers/seamers boost output (15-30 CPM).

ROI Note: Automation pays off long-term in labor savings and consistency.

3. Regulatory Compliance: Permitting Updates

Federal (TTB) – File amended Brewer’s Notice for increased production.

State/Local – Check for:

Higher excise tax tiers.

Updated health, safety, and wastewater permits.

Zoning laws if expanding facility size.

Pro Tip: Hire a brewery consultant to navigate paperwork efficiently.

A well-structured team, streamlined workflows, and proactive compliance ensure a smooth transition to 15 BBL production. Next, we’ll explore financial planning for scaling success.

Financial & Business Strategy for Scaling to a 15 BBL Brewery

Expanding to a 15 BBL operation requires smart funding, distribution planning, and strategic marketing to ensure profitability and sustainable growth.

1. Funding Your Expansion

Scaling up demands significant capital. Consider these options:

Small Business Loans (SBA 7a/504): Low-interest, long-term financing (typical rates: 5-10%).

Investor Partnerships: Equity financing in exchange for ownership stakes (ideal for rapid growth).

Crowdfunding (e.g., Mainvest, Localstake): Community-backed funding with rewards or revenue-sharing.

Equipment Leasing: Lowers upfront costs (fermenters, canning lines).

Key Metric: A well-structured 15 BBL brewery typically requires $500K–$1M+ in total investment.

2. Distribution Expansion: Maximizing Reach

With larger batches, you’ll need to expand sales channels:

Self-Distribution (if state laws allow): Higher margins but requires sales staff and vehicles.

Wholesalers/Distributors: Faster market penetration but lower profits (30-50% margin loss).

Packaging Mix:

Cans – Better for retail, longer shelf life.

Kegs – Ideal for local bars/restaurants.

Tip: Start with local self-distribution before expanding regionally with wholesalers.

3. Marketing & Brand Positioning

Leverage your increased scale for competitive pricing and visibility:

Rebranding (if needed): Ensure packaging and messaging appeal to broader markets.

Pricing Strategy: Lower per-unit costs allow competitive wholesale pricing.

Local Collaborations: Partner with restaurants, festivals, and retailers for promotions.

Digital Marketing: Boost social media, SEO, and e-commerce (direct-to-consumer sales).

Pro Move: Use limited-edition releases to drive urgency and taproom traffic.

A clear financial plan, scalable distribution, and strong branding are critical for 15 BBL success. Next, we’ll discuss common pitfalls and how to avoid them.

Common Pitfalls When Scaling to a 15 BBL Brewery (And How to Avoid Them)

Expanding to a 15 BBL system is exciting but risky. Many breweries stumble due to unexpected costs, overproduction, or equipment mistakes. Here's how to steer clear of major pitfalls.

1. Underestimating Utility Costs

Problem:

A 15 BBL system uses 5-10x more water and energy than nano setups.

Many brewers forget to account for wastewater fees, high-voltage upgrades, or gas boiler costs.

Solution:

✔ Audit utility needs early – Consult local providers for commercial rates.

✔ Invest in efficiency – Recapture heat (HERMS), reuse cooling water, install LED lighting.

✔ Budget a 20% buffer – Unexpected spikes happen.

2. Overproduction Without Sales Channels

Problem:

Brewing 15 BBL batches without buyers leads to spoiled beer, cash flow crises, and discount dumping.

Solution:

✔ Pre-sell batches – Secure contracts with bars/distributors before scaling.

✔ Start small – Test demand with limited 7-10 BBL batches first.

✔ Diversify sales – Taproom, e-commerce, and local events reduce reliance on wholesale.

3. Equipment Mismatches

Problem:

A 15 BBL brewhouse with 15 BBL fermenters creates bottlenecks (no room for double batching).

Undersized glycol chillers or pumps cripple production.

Solution:

✔ Right-size key equipment –

Fermenters = 2x brewhouse size (e.g., 30 BBL for 15 BBL batches).

Glycol chiller = 1 HP per 5 BBL of tank capacity.

✔ Buy modular – Choose expandable systems (e.g., stackable fermenters).

Bonus: Other Pitfalls to Watch

Ignoring local regulations (e.g., zoning for larger tanks).

Understaffing – 15 BBL requires 3-5 full-time employees minimum.

Skipping QC labs – At scale, one infected batch can cost $10K+.

Tip

"Scale with contracts, not just capacity." Secure buyers first, then brew. Next, we’ll wrap up with key takeaways for a smooth transition.

Conclusion: Scaling to a 15 BBL Brewery Successfully

Scaling from nano to 15 BBL requires strategic planning—assessing demand, investing in the right equipment, optimizing workflows, and securing sales channels. While challenges like cost overruns, overproduction, and compliance hurdles exist, meticulous preparation minimizes risks.

Growth is bold but rewarding. Learn from breweries that’ve successfully scaled, and don’t hesitate to consult experts or peers in the industry. Ready to take the leap? Start with a feasibility plan, then brew forward with confidence.

Next Steps:

Connect with 15 BBL brewers for advice.

Download our brewery scaling checklist.

Subscribe for more pro brewing insights.

Professional Brewery Equipment for Nano & 15 BBL Breweries

Upgrade your brewery with high-quality, customizable brewhouses, fermenters, and complete brewing systems—whether you're a nano startup or scaling to 15 BBL production.

Why Choose Us?

✔ Tailored Solutions – From compact 1 BBL nano systems to automated 15 BLL turnkey breweries.

✔ Global Expertise – Trusted by craft brewers in North America, Europe, Asia, and beyond.

✔ Premium Materials – 304/316 stainless steel, sanitary welds, and CE-certified components.

✔ Full-Cycle Support – Design, installation, training, and after-sales service.

Featured Equipment:

Brewhouses (Electric, Steam, Direct Fire)

Fermentation & Brite Tanks (30-60 BBL for scaling)

CIP Systems, Glycol Chillers, Canning Lines

Contact Us Today!

Website: https://www.senmobrew.com/ | Email: admin@senmobrew.com | Phone: +8615550449953

Let’s Build Your Brewery’s Future—Together.