In the world of craft brewing, precision and craftsmanship are paramount. Introducing our 300L beer brewhouse, a compact yet powerful brewing system designed to empower brewers with the tools they need to create exceptional beers. From mashing to lautering, boiling, and whirlpooling, our brewhouse is crafted to elevate your brewing experience to new heights.

300L beer brewhouse introduction

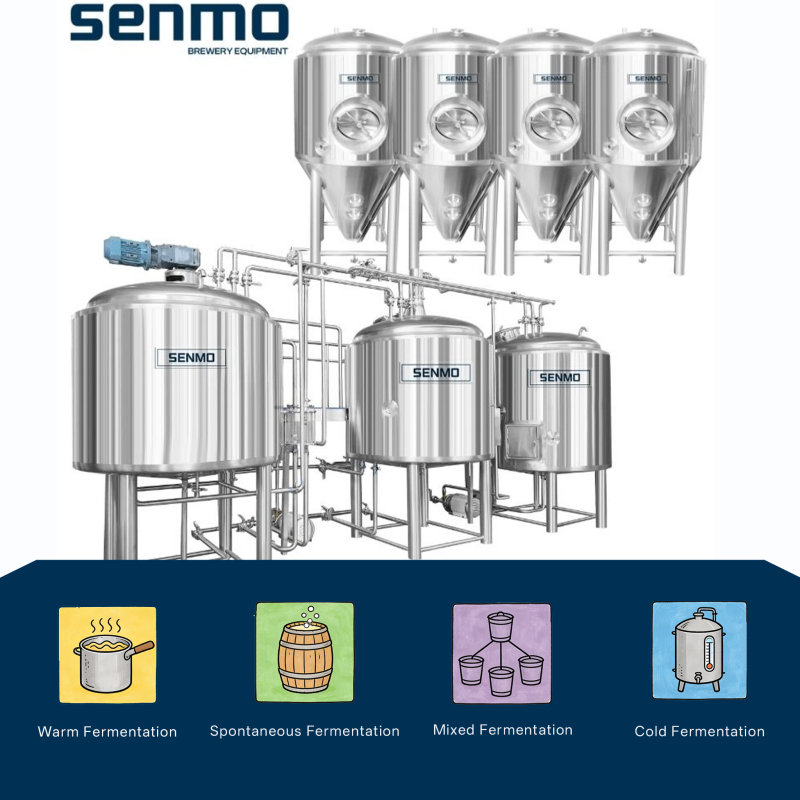

This is our 300L beer brewhouse for microbreweries and brewpubs.It is combined 3-vessel brewhouse system which includes Mash/lauter tun,Kettle/whirlpool tun and wort storage tank.The 300L beer brewhouse is heated by steam,there are steam jackets around the mash tun wall and the brew kettle.The whole 300L brewhouse vessels are made of high standard SUS304 plate,double-layer with rock wool insulation,the inner tank thickness is 3mm,outer wall is 2mm.

There is sparging coil with stainless steel spray nozzles inside of the mash tun to wash the grains,and the rotate CIP balls are equipped inside of the 300L mash tun. It has rotate rake arm to agitate and cut the grain bed.The sieve plate can be took out to clean the bottom of the lauter.

The 300L brew kettle has two holes in the bottom,the lowest one is for drain outlet,the other one is for clear wort outlet after wort whirlpooling.There is a separate plate to divide the hops,grains and other material which need to drain out. The tangent whirlpool inlet is on the side of the vessel.

Besides of the main vessels,there are pipes,pumps,valves and other accessories inside of the 300L beer brewhouse.

Easy Cleaning and Maintenance

Designed with brewers in mind, our brewhouse facilitates easy cleaning and maintenance. Quick disassembly and access points ensure a thorough cleaning process, minimizing downtime between batches.

Cleaning and Care Guide

Our 300L beer brewhouse is tailor-made for brewers to ensure easy cleaning and maintenance processes. Here are some suggestions to ensure your equipment remains hygienic and minimizes downtime between operations:

1. Quick disassembly design:

The device's quick-release design is key to simplifying the cleaning process. Make sure you can easily disassemble key components when cleaning so you can more thoroughly clean each part.

2. Flush the system regularly:

After each brewing cycle, it is recommended to perform regular flushing through the system. Using a cleaning solution, make sure all pipes, valves and containers are flushed to prevent the build-up of residue.

3. Use special cleaning agents:

Choose a cleaner designed for stainless steel equipment to avoid damage to the surface. This ensures that the device maintains its appearance and performance throughout its service life.

4. Pay attention to the heating element:

Check and clean the heating element regularly to ensure that excessive dirt has not accumulated on its surface. This helps maintain the efficiency and performance of your heating system.

5. Lubricate key components regularly:

Lubricate critical moving parts on equipment to ensure their smooth operation during operation. This includes valves, knobs and other moving connection parts.

6. Inspection after cleaning:

After cleaning is complete, conduct a careful inspection to ensure that all parts are installed correctly and intact. This helps prevent potential problems and ensures a smooth brewing process for the next batch.

7. Preventive maintenance plan:

Develop a preventive maintenance plan with regular comprehensive inspections and maintenance. This can help you detect potential problems before they happen and prevent long-term wear and tear on your equipment.

8. Train winemakers:

Provide your winemakers with cleaning and maintenance training to ensure they understand the proper use and care of their equipment. This helps maximize the life of your equipment.

By following these tips, you'll be able to easily keep our 300L beer brewhouse clean and minimize downtime during maintenance. This helps ensure your equipment is always in top working order, providing reliable support for your brewing process.

Environmental considerations in equipment design and manufacturing

Our 300L beer brewhouse is built with a commitment to environmental responsibility and sustainability. During the design and manufacture of the equipment, we paid special attention to a range of environmentally friendly features to ensure that the brewing process is not only efficient but also environmentally friendly.

1. Energy-saving design:

The equipment features an advanced energy-saving design designed to minimize energy consumption. This includes optimized insulation materials, efficient heating and cooling systems, and scheduled start and stop functions to ensure that the equipment can minimize power consumption when not needed.

2. Efficient energy recovery system:

Our brewing equipment incorporates energy recovery technology by recapturing energy during waste heat generation and using it for other parts of the brewing process. This system helps reduce dependence on external energy and improve energy efficiency.

3. Wastewater treatment system:

The equipment is equipped with an advanced wastewater treatment system to minimize the environmental impact of wastewater generated during the brewing process. By effectively treating and filtering wastewater, we work to ensure discharges comply with environmental regulations and minimize water consumption.

4. Circulating water utilization system:

The equipment is integrated with a recycling water utilization system to recycle part of the water resources generated during the process. This technology helps reduce water consumption and ensures the equipment has the smallest possible environmental footprint during the brewing process.

5. Selection of environmentally friendly materials:

In the construction of the equipment, we have chosen environmentally friendly materials such as stainless steel, which not only offer excellent corrosion resistance and durability, but also maintain their quality throughout their service life, reducing the need for alternative materials.

6. Environmental certification:

Our equipment actively seeks and obtains environmental-related certifications to ensure that its design and operation comply with international environmental standards. This not only demonstrates our commitment but also provides customers with confidence in using environmentally friendly equipment.

7. Responsible production:

We encourage supply chain sustainability and ensure that the entire process from raw material acquisition to manufacturing and delivery meets environmental and social responsibility standards. This helps reduce pressure on limited resources and promotes sustainability throughout the production process.

By integrating these environmentally friendly features, our 300L beer brewhouse aims to provide a sustainable and environmentally friendly solution to the brewing industry, while providing brewers with efficient, innovative and environmentally friendly tools to help them achieve their contribution to the environment and commitment.

Safety of Our 300L Beer Brewhouse

Our 300L beer brewhouse not only focuses on brewing efficiency and functionality, but is also designed with safety in mind. Here is a closer look at some of the equipment’s safety features to ensure safe operation during the brewing process:

1. Pressure relief valve:

Each tank of the equipment is equipped with a specially designed pressure relief valve. The function of these valves is to promptly release excess pressure accumulated inside during the brewing process to ensure stable operation of the tank. This design not only ensures the safety of the equipment, but also prevents potentially dangerous situations.

2. Safety pressure control system:

The equipment integrates a safety pressure control system that monitors and adjusts the pressure in the tank during the brewing process. Once the pressure reaches the set safety threshold, the system will take automatic measures, such as releasing excess pressure through a relief valve, to ensure that the equipment is always within a safe operating range.

3. Temperature monitoring and control:

The equipment is equipped with a temperature monitoring and control system to ensure that the temperature during the brewing process is always within a safe range. The system can automatically adjust the heating and cooling systems to prevent temperatures that are too high or too low from causing potential danger to equipment and operators.

4. Emergency stop device:

The equipment is designed with an emergency shutdown device that allows winemakers to immediately stop the operation of the equipment when a potential danger or emergency situation is discovered. This feature quickly interrupts the brewing process, ensuring that quick action can be taken if needed.

5. Ergonomic design:

The equipment is designed with ergonomic principles in mind, ensuring that all controls and operating parts are easy to use and understand. Clear markings, easy-to-operate control panels and clear instructions on emergency operating procedures can help reduce the probability of misoperation and accidents.

6. Safety training and documentation:

We provide extensive safety training and documentation to ensure winemakers understand the proper procedures for operating equipment and how to respond to emergencies. This helps increase operator awareness of safe equipment operation.

7. Comply with industry standards and regulations:

The equipment is designed to comply with relevant industry standards and regulations, ensuring safety practices are followed during the brewing process. This includes compliance with pressure vessels, electrical equipment and other related aspects.

By integrating these safety features, our 300L beer brewhouse is designed to provide a safe and secure brewing environment, ensuring brewers can be efficient while minimizing potential risks and safety hazards.

If you want to learn more about this 300L beer brewhouse system,feel free to ask us for inquiry!

FAQ

1. What is the capacity of the 300L Beer Brewhouse?

The 300L Beer Brewhouse has a brewing capacity of 300 liters, making it ideal for small to medium-scale breweries.

2. What materials are used in the construction of the brewhouse?

The brewhouse is constructed using premium 304 stainless steel, ensuring durability, corrosion resistance, and a hygienic brewing environment.

3. How many vessels are included in the brewhouse configuration?

Our 300L Beer Brewhouse adopts a three-vessel configuration, comprising the mash/lauter tun, brew kettle, and whirlpool. This design allows for simultaneous brewing and provides flexibility in the brewing process.

4. Is the brewhouse designed for easy cleaning and maintenance?

Yes, the brewhouse is designed with brewers in mind, facilitating easy cleaning and maintenance. Quick disassembly and access points ensure a thorough cleaning process, minimizing downtime between batches.

5. Can the brewhouse be adapted for different beer styles?

Absolutely, the 300L Beer Brewhouse is versatile and can be adapted for brewing a wide range of beer styles, providing flexibility and creative freedom for brewers.

6. How does the heat exchange system work in the brewhouse?

The brewhouse incorporates an efficient heat exchange system, allowing for precise temperature control during mashing and boiling. This feature ensures the extraction of flavors and aromas essential for crafting distinct and high-quality beers.

7. Is there a control panel for monitoring and adjusting brewing parameters?

Yes, the brewhouse comes equipped with an intuitive control panel, allowing brewers to monitor and adjust temperature, time, and other parameters with ease.

8. Are there any safety features included in the brewhouse?

While the brewhouse is designed for efficiency and functionality, specific safety features include pressure relief valves in vessels to ensure safe operation during the brewing process.

9. Can the brewhouse be used in both new and established breweries?

Yes, the 300L Beer Brewhouse is suitable for both new and established breweries, offering a compact and efficient solution for breweries of various scales.

10. How can I inquire about pricing and make a purchase?

For pricing inquiries and to initiate a purchase, please contact our sales team at admin@senmobrew.com. They will provide you with detailed information, answer any additional questions, and assist you in acquiring the 300L Beer Brewhouse for your brewing needs.

Feel free to reach out to our team for any further questions or to discuss your specific brewing requirements. We're here to help you achieve brewing excellence with our 300L Beer Brewhouse. Cheers to crafting exceptional beers!