4bbl beer brewing equipment for microbrewery

The world of craft brewing is fueled by innovation, passion, and a relentless pursuit of quality. For microbreweries, the choice of brewing equipment plays a pivotal role in their ability to craft exceptional brews. The 4BBL Beer Brewing Equipment is a game-changer for microbreweries, offering the ideal blend of capacity, precision, and versatility.

Our 4bbl beer brewing equipment for microbrewery

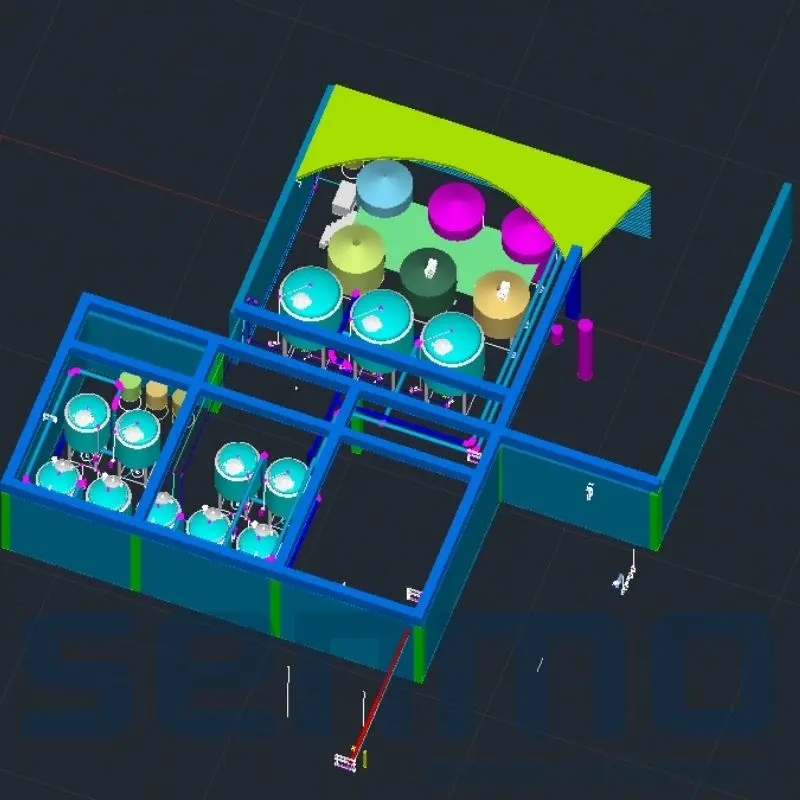

This is our microbrewery 4bbl beer brewing equipment for microbrewery. It is our new designed brewhouse system for the brewpub,restaurant and microbrewery.On the left side,the whole vessel include two tuns,on the top is the 4bbl mash tun,under the mash tun is the 4bbl hot water tank,we can use the hot water tank as 4bbl wort storage tank. On the right side,it is the 4bbl wort kettle,the 4bbl kettle also has whirlpool function.The whole 4bbl microbrewery beer brewing equipment plates and accessories are made of international standard SUS304 stainless steel; Laser cutting and argon shielded welding, internal centralized pickling and passivation, accuracy ≤ 0.4 μ m;

Steam jacket around the 4bbl mash tun and 4bbl wort kettle: working pressure 0.15MPa, test pressure 0.4MPa, super large heating area, heating rate 1-1.2 ℃/min, automatic temperature control; The 4bbl boiling kettle is equipped with forced circulation to support boiling under pressure, ensuring 8-12% boiling strength, improving the utilization rate of heat energy, and can optionally be equipped with condensate recovery device;The whirlpool circulates tangentially, and the high and low liquid level discharge ports are equipped with baffles for hot solidified substances and hops decomposition substances;

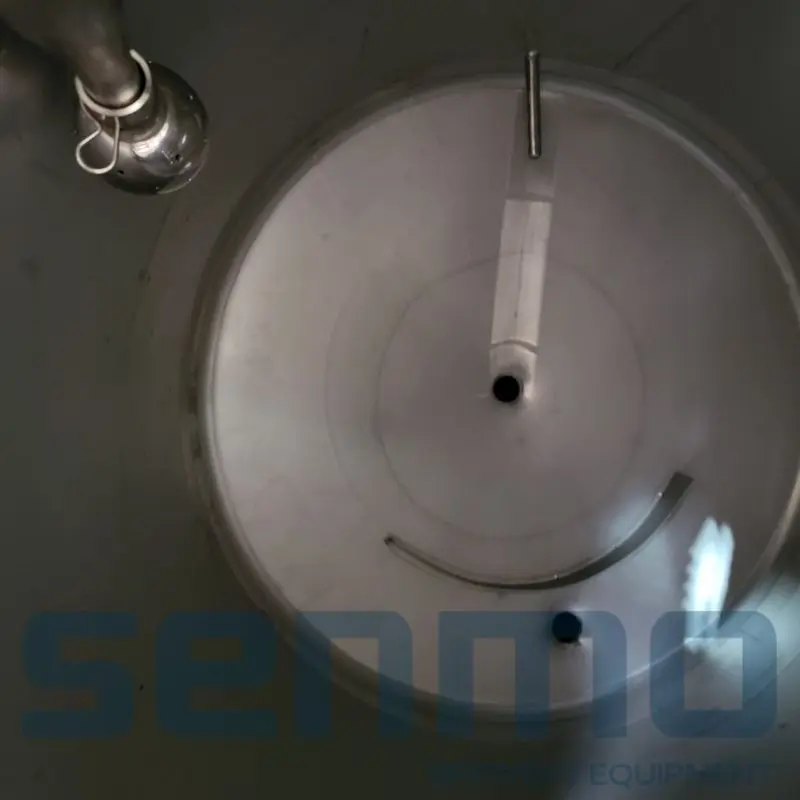

Variable frequency automatic lifting plough cutter for 4bbl Mash/lauter tun, removable milling sieve plate, spacing 0.7mm, opening rate greater than 17%, multiple supporting points at the bottom, and backwashing device to reduce sanitary dead angle; The brewhouse has high precision temperature sensor, pressure sensor, liquid level sensor and other components, Siemens PLC control, program input, multi process formula storage and setting, simple operation;Accessories of auxiliary machines are selected from domestic and foreign first-line brands, which are CE/UL certified.

The following fittings are matched with the 4bbl fermenters:

-Mechanical pressure regulating valve

-Beer sample valve

-Breath valve

-Thermometer

-Hops dosing port

-Temperature sensor

-Beer rotary pipe

-Drain outlet

-CIP ball and CIP arm

-CO2 carbon stone

The connection of the fittings can be tri-clamp,diary couplers and other connection way you want.Meanwhile,if you need other fitings or port on the fermenters,you can tell us and we do the special design for you.

Our Microbrewery 4BBL Beer Brewing Equipment is a game-changer for those who are passionate about crafting exceptional beer. With innovative design, versatility, high-quality materials, precision, and unwavering support, it empowers small-scale brewers to create high-quality brews consistently. Craftsmanship, innovation, and a commitment to quality are at the core of this brewing system, and it's poised to elevate your craft to new heights. Whether you're a small startup or an established microbrewery, this equipment is a valuable asset in the pursuit of brewing excellence.

If you are considering entering the brewing beer or craft beer industry. Whether it is investing in bars,breweries, restaurants, or small and medium-sized breweries, it is necessary to have a clear understanding of the requirements for beer brewing technology and equipment technology configuration. If you have any questions, please communicate with beer brewing professionals and beer brewing equipment manufacturers in detail. Shandong SENMO Machinery Co., Ltd., as a professional beer equipment production service provider, provides you with professional technical consultation in the early stage, and carries out equipment design, production, installation, commissioning and other services according to the requirements of beer brewing technology.

FAQ

Q1: What is the capacity of the 4BBL beer brewing equipment, and is it suitable for small-scale breweries?

A1: The 4BBL beer brewing equipment has a 4-barrel capacity, making it an excellent choice for small-scale breweries, brewpubs, and restaurants. It strikes a perfect balance between production capacity and space efficiency, catering to the needs of microbreweries.

Q2: Can the hot water tank be used for other purposes besides hot water storage?

A2: Yes, the hot water tank can be used as a 4BBL wort storage tank, offering versatility in the brewing process. This flexibility allows brewers to adapt to different brewing styles and recipes.

Q3: What are the benefits of using SUS304 stainless steel in the equipment's construction?

A3: SUS304 stainless steel is known for its exceptional durability and corrosion resistance. It ensures that the equipment remains in top condition, even in the demanding brewing environment, contributing to the longevity and quality of the brews produced.

Q4: How precise is the equipment's construction, and how does it contribute to the brewing process?

A4: The equipment is constructed with meticulous attention to detail, achieving an accuracy level of ≤ 0.4 μm. This precision not only ensures the equipment's longevity but also maintains a high level of hygiene in the brewing process, preventing the risk of contamination and contributing to consistent and high-quality brews.

Q5: Is installation guidance and support provided for this equipment?

A5: Yes, we provide installation guidance and support for our customers. Our team is readily available to assist with installation, and we also offer ongoing support, maintenance guidance, and troubleshooting assistance to ensure a smooth brewing experience.

Q6: Can this equipment be expanded or scaled up as our microbrewery grows?

A6: Yes, the 4BBL beer brewing equipment is designed with scalability in mind. It can be expanded to accommodate the growing needs of your microbrewery, allowing you to increase your production capacity without the need for a complete equipment overhaul. This scalability is a cost-effective solution for future growth.