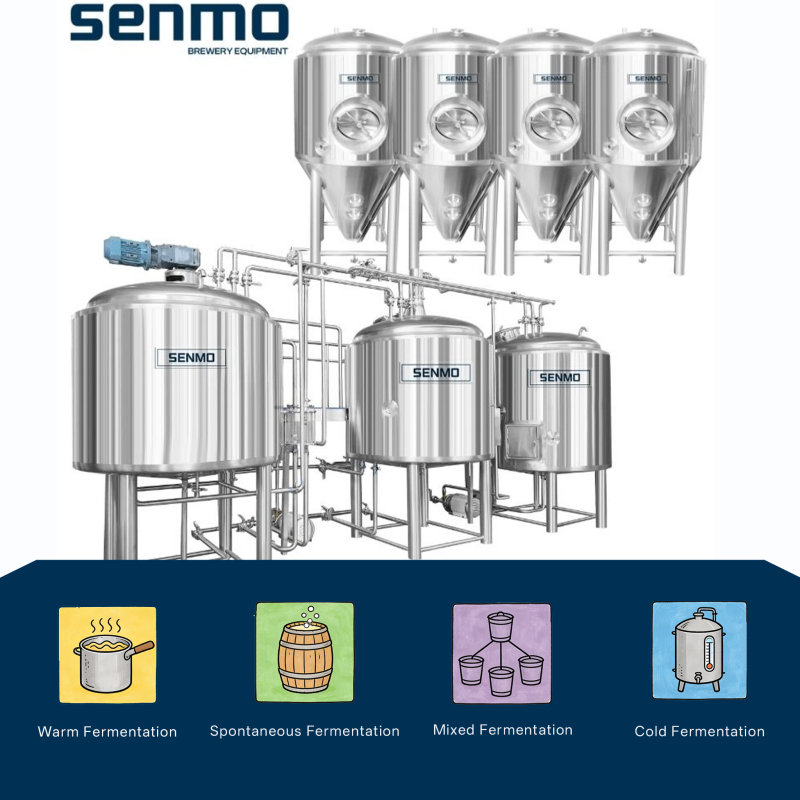

500 litre combined brewing equipment

The term "500L combined brewing equipment" refers to a brewing system with a total capacity of 500 liters, typically used in the beer brewing process. This type of brewing equipment is designed to handle various stages of the brewing process, combining multiple vessels and functionalities into a single integrated system.

Key Components of 500L Combined Brewing Equipment:

Mash/Lauter Tun: This vessel is used for mashing, where crushed grains are mixed with hot water to convert starches into fermentable sugars. Lautering is the process of separating the liquid wort from the solid grain husks.

Brew Kettle: The brew kettle is where the wort is boiled and hops are added for flavor, aroma, and bitterness. Boiling also helps sterilize the wort.

Whirlpool Vessel: After boiling, the wort is transferred to the whirlpool vessel, where it is gently stirred to create a whirlpool effect. This separates the trub and hop residues, ensuring a clear wort for fermentation.

Fermentation Tanks: These tanks are used for the fermentation process, where yeast is added to the cooled wort to convert sugars into alcohol and carbon dioxide, resulting in beer.

Cooling System: A cooling system is integrated into the brewing equipment to rapidly cool down the wort after boiling, bringing it to the desired fermentation temperature.

Control Panel: The control panel provides brewers with precise control over various parameters, such as temperature, time, and pumps, allowing for automation and consistency in the brewing process.

Advantages of 500L Combined Brewing Equipment:

Compact Footprint: Combining multiple vessels into a single system reduces the equipment's overall footprint, making it suitable for breweries with limited space.

Efficiency: The integrated design streamlines the brewing process, reducing the need for manual handling and increasing overall brewing efficiency.

Consistency: The centralized control panel enables brewers to maintain consistent brewing parameters, resulting in reproducible and high-quality beer batches.

Flexibility: Breweries can produce a variety of beer styles with the same system by adjusting the brewing parameters and ingredients.

Scalability: Combined brewing equipment can be designed to be scalable, allowing breweries to expand production capacity as their business grows.

Applications of 500L Combined Brewing Equipment:

The 500L combined brewing equipment is suitable for craft breweries, brewpubs, and microbreweries looking to produce small to medium-sized batches of beer. Its versatility, efficiency, and scalability make it an ideal choice for brewers seeking to create unique and high-quality craft beers while optimizing their brewing operations.

It is our 500L combined brewing equipment for sale. It is steam heating brewing equipment,you can also choose other heating methods as per you local energy cost,there is electric tubes heating way and fire directly heating way for this 500l brewing kit.The reason some brewers choose this combined brewing equipment manily because of the cost performance and the small area needed.This design can meet various brewing technologies,so it is a good option for some breweries startup.

On the left side of the 500l combined brewing equipment is Mash/lauter tun and Wort storage tank,you can see the two doors on each vessel.Meanwhile,the wort storage tank can be act as the hot liquid tank.

On the right side of the brewing equipment is Kettle/whirlpool tun,with indoor exhaust device,if you want to exhaust the steam out of your brewery,then we can make the device to your wall,in that case,the steam can be go to outside through the tube.

The manhole of the 500liter brewing equipment use full glass type,and it is quick opening manhole. The brewers can see the wort processing clearly through the glass manhole. It is easy to operate and easy to clean. There will be a LED sight light next to the manhole,it makes the inside of the brewing equipment light.By the way,we can print your brewery logo on the glass manhole,which makes the equipment more customized.

This is the hop back tank in the 500l combined brewing equipment for sale,it is stainless steel 304 material,with mesh filter inside of the tank.It is connected between the whirlpool tun and the plate heat exchanger,the function of the hop back tank is filtering the sediment after whirlpool,the other important function is that you can put the spices such as hops,citrus peel inside it,to add extra aroma and flavor into the beer.

Th is 500L side manhole beer fermentation tank for sale.It is double wall with insulation,with cooling jackets around the inner wall.If you want single wall fermenters or bright beer tank,we can do the special design for you. It is pressured tanks,our test pressure on the tank is 4Bar(0.4Mpa).The following valves will be matched if you buy the 500L fermenter.

Mechanical pressure valve

Pressure gauge

Safety valve

Beer sample valve

Beer racking arm

CIP ball and arm

Butterfly valves

What SENMO can provide for you

Sales consulting. Provide fast, professional and detailed configuration list according to customer requirements.

Brewery technical design. According to the concept of customization, put forward design suggestions, integrate customer requirements, issue process flow diagrams, floor plans, containers, machinery, electrical and other drawings, draw 3D renderings, and provide one-to-one tracking services.

Beer equipment processing and manufacturing. Strictly implement the requirements of design drawings, follow the IOS9001 quality management system, strictly control the quality of all links, and provide test records of plates, welding, polishing, pressure, etc. for filing.

Delivery and installation. The professional microbrewery project construction team conducts on-site installation, commissioning and training to ensure accurate delivery for use and continuous tracking maintenance.

If you have plan to build a microbrewery,the 500litre combined brewing equipment for sale is a good option.Please send us inquiry,we will have sales engineer contact with you and give your more professional suggestions. Cheers!

FAQ

Q1: What is the capacity of the 500L combined brewing equipment?

A: The 500L combined brewing equipment has a total capacity of 500 liters, which includes the combined volume of all the vessels in the system.

Q2: What are the key components included in the 500L combined brewing equipment?

A: The key components of the 500L combined brewing equipment typically include a Mash/Lauter Tun, Brew Kettle, Whirlpool Vessel, Fermentation Tanks, Cooling System, and a Control Panel for automation and precise control.

Q3: Is the 500L combined brewing equipment suitable for small breweries or brewpubs?

A: Yes, the 500L combined brewing equipment is well-suited for small craft breweries, brewpubs, and microbreweries. It allows them to produce small to medium-sized batches of beer efficiently and with consistent quality.

Q4: Can the 500L combined brewing equipment be customized to suit specific brewing needs and recipes?

A: Absolutely! The 500L combined brewing equipment can be customized to accommodate specific brewing recipes and preferences. Brewers can adjust various parameters such as temperature, time, and ingredients to create a wide variety of beer styles.

Q5: What are the advantages of using combined brewing equipment?

A: The combined brewing equipment offers several advantages, including a compact footprint, increased brewing efficiency, centralized control for consistent results, flexibility in brewing different beer styles, and scalability to accommodate future growth.

Q6: Is technical support and training provided with the purchase of the 500L combined brewing equipment?

A: Yes, reputable manufacturers of the 500L combined brewing equipment usually provide comprehensive technical support and training. They offer installation assistance, operational training, and ongoing support to ensure brewers are confident in using the equipment effectively.

Q7: Can the 500L combined brewing equipment be expanded to increase production capacity?

A: Yes, the 500L combined brewing equipment can be designed to be scalable. As a brewery's demand and production grow, additional fermentation tanks and other components can be added to increase production capacity while maintaining the same brewing quality.

Q8: What types of beer can be brewed with the 500L combined brewing equipment?

A: The 500L combined brewing equipment allows brewers to produce a wide range of beer styles, including ales, lagers, stouts, porters, and more. With the ability to adjust brewing parameters, brewers have the flexibility to experiment and create unique and diverse beer offerings.

Q9: Is the 500L combined brewing equipment suitable for commercial use?

A: Yes, the 500L combined brewing equipment is designed for commercial use and is commonly used by craft breweries, brewpubs, and smaller-scale beer producers.

Q10: How can I get more information and place an order for the 500L combined brewing equipment?

A: To get more information and place an order for the 500L combined brewing equipment, please contact our sales team. They will be happy to provide you with all the details, answer any additional questions, and guide you through the ordering process. Cheers to your brewing success!

Q11: Can the 500L combined brewing equipment be equipped with advanced automation features?

A: Yes, the 500L combined brewing equipment can be integrated with advanced automation features. Automation not only enhances brewing efficiency but also allows brewers to have better control over the brewing process, ensuring consistent and repeatable results.

Q12: Is the 500L combined brewing equipment easy to clean and maintain?

A: Yes, the 500L combined brewing equipment is designed with ease of cleaning and maintenance in mind. The use of high-quality stainless steel materials facilitates cleaning and ensures the equipment remains hygienic for producing high-quality beer.

Q13: Can I use the 500L combined brewing equipment for pilot brewing or recipe testing?

A: Absolutely! The 500L capacity is suitable for pilot brewing and recipe testing before scaling up to larger production volumes. It allows brewers to experiment with new recipes and fine-tune their formulations with minimal raw material wastage.

Q14: What types of heating options are available for the 500L combined brewing equipment?

A: The 500L combined brewing equipment can be equipped with various heating options, such as electric heating elements, steam heating, or direct-fire heating. The choice depends on the specific preferences and utilities available in the brewery.

Q15: Can the 500L combined brewing equipment be installed on-site with ease?

A: Yes, reputable manufacturers provide on-site installation services, ensuring that the 500L combined brewing equipment is properly set up and ready for use. They also offer guidance and support during the installation process.

Q16: Does the 500L combined brewing equipment come with safety features?

A: Yes, safety is a priority in brewing equipment design. The 500L combined brewing equipment is equipped with safety features, such as temperature sensors, pressure relief valves, and emergency shut-off mechanisms to ensure safe brewing operations.

Q17: Can the 500L combined brewing equipment accommodate future upgrades or modifications?

A: Depending on the manufacturer and design, the 500L combined brewing equipment can be adaptable to accommodate future upgrades or modifications. This flexibility allows breweries to stay up-to-date with technological advancements and evolving brewing practices.

Q18: How long does it take to brew a batch using the 500L combined brewing equipment?

A: The time required to brew a batch using the 500L combined brewing equipment varies depending on the specific recipe and brewing process. On average, the brewing process may take several hours, including mashing, boiling, and fermentation periods.

Q19: Is the 500L combined brewing equipment energy-efficient?

A: The energy efficiency of the 500L combined brewing equipment can vary based on the heating method used and the brewery's overall setup. Choosing energy-efficient heating options can help reduce operational costs and environmental impact.

Q20: Can I visit the manufacturer's facility to see the 500L combined brewing equipment in action?

A: Yes, many manufacturers welcome brewery visits, allowing potential buyers to witness the brewing equipment in operation, get a closer look at the craftsmanship, and gain insights into its capabilities before making a purchase decision.

For more details, technical specifications, and to explore the possibilities of the 500L combined brewing equipment, feel free to reach out to our sales team. We are committed to providing you with the best brewing solutions to elevate your craft beer journey. Cheers to creating exceptional brews with the 500L combined brewing equipment!