Beer Brewing Methods: Types, Processes, Best Equipment Solutions

Beer brewing is both an art and a science. Across centuries and continents, brewers have innovated, refined, and reinvented brewing techniques to produce distinct flavors, textures, and beer styles. With shifts in consumer preferences and industry growth, understanding brewing methods—not just styles—is essential for breweries of all scales.

In this article, we explore beer brewing methods comprehensively, supported by data, and highlight solutions for breweries aspiring to optimize quality and efficiency.

The Global Brewing Landscape: Key Industry Data

To contextualize brewing methods, it’s important to first grasp the global beer industry’s scale and dynamics.

Global Beer Industry Overview

| Metric | Value (2022–2025) |

|---|---|

| Global beer industry valuation | ~$623 billion (2022) |

| Craft beer market share (US) | ~25% of total beer market |

| Number of breweries worldwide | ~18,000+ (2022) |

| US craft breweries (2024) | ~9,796 operating breweries |

| Craft beer retail dollar sales (US) | $28.8 billion (2024) |

Despite recent declines in craft beer production volumes in some regions like the U.S., the overall number of breweries and retail value remain robust, reflecting changing market structures and consumer tastes.

Core Beer Brewing Methods Explained

Beer brewing can be classified into several fundamental methods, each driven by science, equipment, and desired style outcomes.

A. Traditional Batch Brewing

This is the most common method used by craft and commercial breweries:

Stages of Batch Brewing

Malting: Barley is germinated and dried to convert starches into fermentable sugars.

Milling: Grains are crushed to expose starches.

Mashing: Ground grains are mixed with hot water—enzymes break down starches into sugars (wort).

Boiling: Wort is boiled and hops are added for bitterness, flavor, and aroma.

Fermentation: Yeast converts sugars into alcohol and CO₂.

Conditioning: Beer matures to develop its final flavor profile.

Packaging.

This process typically takes 4–6 weeks to complete from grain to packaged product.

B. Infusion vs. Decoction Mashing

Both are mash techniques that affect flavor and body:

| Technique | Description |

|---|---|

| Infusion mashing | Heating grains in a single vessel; simple and efficient. |

| Decoction mashing | Removes a portion of the mash to boil separately; enriches malt complexity. |

Decoction is traditional in European lagers and contributes rich, caramelized malt character.

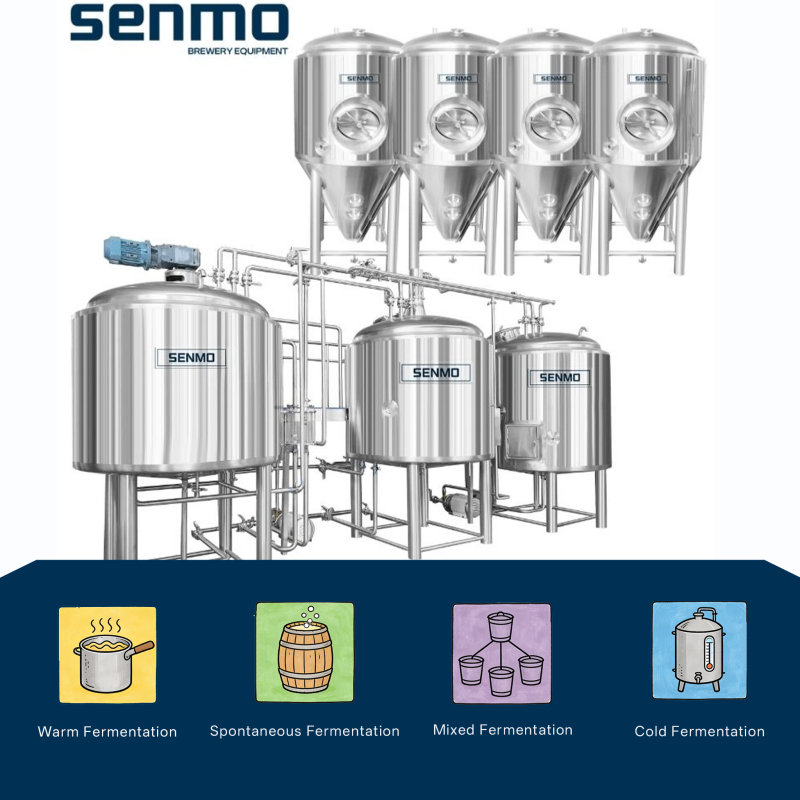

Fermentation Methods: Shaping Beer Styles

Yeast selection and fermentation style are arguably the most critical factors defining beer type.

A. Ale vs. Lager Fermentation

| Fermentation Type | Yeast | Temperature Range |

|---|---|---|

| Ale | Saccharomyces cerevisiae | 15–24 °C (Warm) |

| Lager | Saccharomyces pastorianus | 7–13 °C (Cool) |

Ale fermentation is faster and produces fruity or complex esters, while lager fermentation is slower, yielding clean, crisp profiles.

B. Spontaneous and Mixed Fermentation

Some historic and sour beers use wild yeast and bacteria:

Spontaneous Fermentation: Exposes wort to ambient organisms (e.g., in Lambic beers).

Mixed Fermentation: Combines yeast and bacteria (e.g., Lactobacillus for sour beers).

These techniques produce tart, funky, or complex beers but require longer ageing and specialized facility hygiene.

Specialty & Modern Brewing Techniques

Today’s brewers are pushing beyond basics with innovative methods targeting flavor, aroma, and efficiency.

A. Dry Hopping & Cryo-Hopping

Dry Hopping: Hops added post-fermentation to enhance aroma without adding bitterness.

Cryo-Hopping: Uses concentrated cryogenically extracted hop resins for intense flavor impact.

B. Continuous Fermentation

Unlike batch fermentation, continuous fermentation feeds wort and removes beer steadily, allowing consistent quality and faster output—ideal for larger scale breweries.

C. AI-Driven Brewing

Emerging systems monitor fermentation conditions in real-time and optimize yeast performance, carbonation, and flavor outcomes.

Comparative Table: Brewing Methods & Characteristics

| Method | Primary Use | Flavor Impact | Time Required |

|---|---|---|---|

| Batch Brewing | All general beers | Balanced | Moderate |

| Decoction Mashing | Traditional lagers | Rich & malty | Longer |

| Spontaneous Fermentation | Lambic & sours | Unique, funky | Very long |

| Continuous Fermentation | High-volume | Consistent | Faster than batch |

| AI-Assisted Brewing | Commercial precision | Very controlled | Varies |

Sustainability & Efficiency Trends in Brewing

Breweries are increasingly adopting techniques that reduce resource use and environmental impact:

Water-Saving Technologies: Some breweries have achieved up to 40% water reduction through new hydration control and recycling systems.

Energy Efficiency: Heat exchange systems and AI process control can lower energy consumption without affecting beer quality.

Reuse & Circular Practices: Spent grains are repurposed for animal feed or biogas.

These trends align with consumer demand for environmentally conscious products and lower operating costs.

Choosing the Right Brewing Equipment

Selecting the right equipment is critical for operational efficiency and product consistency. Brewery requirements vary with brewing method:

| Method | Recommended Equipment Features |

|---|---|

| Traditional Batch | Standard mash tuns, kettle, fermenters |

| Decoction | Precision mash control systems |

| Spontaneous | Open coolship and traditional barrels |

| Continuous | Specialized fermenters with feed/removal systems |

| High-Volume | Automation & AI control systems |

View related products:

7BBL Brewing system equipment for micro brewery

Turnkey 5000L industrial beer brewery equipment

Why Equipment Quality Matters

Great brewing techniques require equally great equipment:

Consistent mash temperatures and timelines maximize sugar extraction and yield.

Precision fermentation controls ensure yeast performance and flavor integrity.

Quality stainless steel and copper vessels improve sanitation and longevity.

Automated systems reduce labor, error, and operating costs.

If you need brewing equipment, please contact Senmo.

Conclusion: Brewing Methods Shape Beer — and Success

From traditional decoction mash to cutting-edge AI-managed fermentation, brewing methods dramatically influence beer character and operational efficiency. Understanding these methods—with data-driven benchmarks—helps breweries innovate sustainably, adapt to market trends, and delight their consumers.

With beer consumers increasingly seeking quality, artisan flavor, and consistency, professional equipment investment is essential.

Solution Recommendation: Shandong Senmo Machinery Company

For breweries aiming to excel in quality brewing regardless of method—traditional or modern—Shandong Senmo Machinery Company offers comprehensive tailored solutions:

Why Choose Shandong Senmo?

Located in Jinan, known as China’s center of beer equipment production

Over 2,000 m² workshop, 80+ production staff, 20+ sales & service experts

Goal: Become a top beer equipment manufacturer in China

One-stop turn-key service for microbreweries, brewpubs, and restaurant breweries

Over 9 years of R&D and 50+ product varieties including craft beer systems, fermenters, filling machines, and dispensers

5-year warranty and overseas installation support

Certified with CE, IOS, and UL

Fast delivery: 60 working days

Custom voltages, materials (SUS304, SUS316, copper), and control modes (automatic to manual)

Exported to 20+ countries with strong global support network

Whether you’re launching a new brewery or upgrading an existing one for advanced fermentation control, Sanmo offers reliable, customizable equipment engineered to support any brewing method.

See some Senmo case studies:

2000L turnkey microbrewery plant for Asian client

7bbl beer equipment for microbrewery in Canada

Related Frequently Asked Questions

What brewing method produces the most flavor complexity?

Traditional multi-step techniques like decoction mashing and mixed/sour fermentation typically yield richer, more nuanced flavor profiles.

How long does brewing usually take?

Standard beer takes approximately 4–6 weeks from grain to finished product.

Does equipment choice influence beer flavor?

Absolutely. Precision boil kettles, mash controls, and fermenters significantly impact consistency and flavor outcomes.