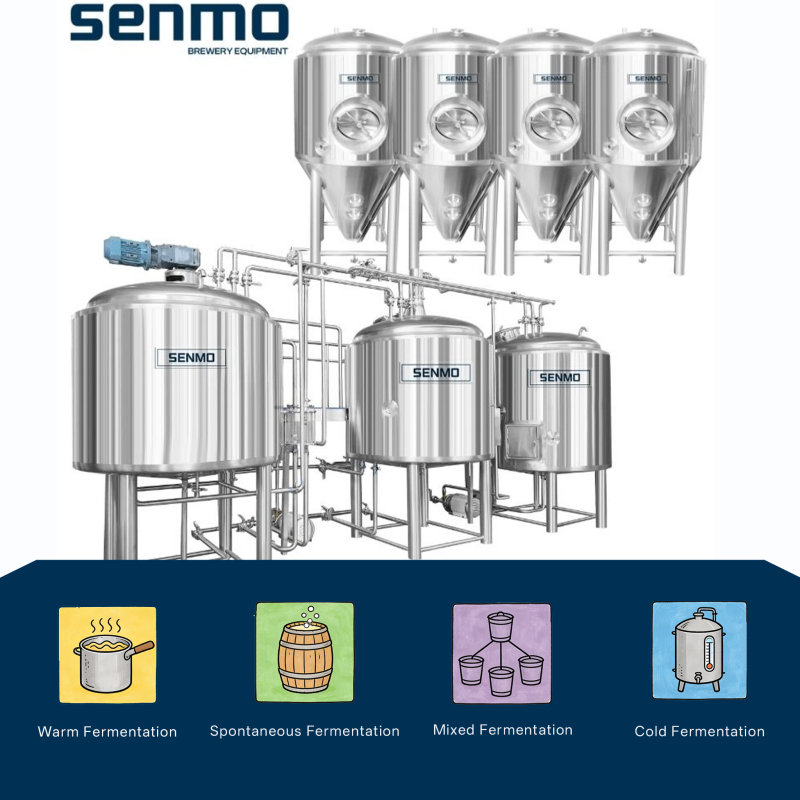

5BBL beer brewing equipment for microbrewery

This is a set of 5bbl beer brewing equipment for microbrewery,the whole 5bbl beer brewing equipment include malt milling system,5bbl beer brewing system,5bbl fermentation system,cooling system,CIP system and control system.The whole 5bbl brewery setup cost small area,30m2 will be OK for the equipment.Meawhile,the operation of the 5bbl beer brewing equipment is easy,one brewer can operate it,there are semi-automatic or fully automatic can be choosed as per your requirements.

The beer brewing system and beer fermentation system are the two main parts inside of the microbrewery,below is the detailed instruction of the components of the 5bbl brewing system:

5bbl mash tun features

Working volume:5BBLTotal volume:6BBL

Design temperature:Min:0℃ Max:100℃Design pressure:Atmosphere

Inner tank thickness:2.5mmOuter tank thickness:2mmSurface process of the tank:Brushed surface

Head type:Conical head

Insulation material and thickness:Rock wool,80mm

Agitation type:Motor Bottom agitation,With Frequency control,Power:0.75kw, Speed ratio: 1:29

Steam jackets thickness:1.5mmPosition:Around middle cylinder and bottom cone

Manhole type and diameter:All glass manhole,φ500mm

Chimney:600mm

Four stainless steel legs, with screw assembly to adjust leg height, the base plate with two fixed hole;

Fittings of the tun:2 CIP ballsLED lightPT-100 temperature probeOther matched valves

5bbl lauter tun features

Working volume:5BBLTotal volume:6BBL

Design temperature:Min:0℃ Max:100℃Design pressure:Atmosphere

Inner tank thickness:2.5mmOuter tank thickness:2mmSurface process of the tank:Brushed surface

Head type:Conical head

Insulation material and thickness:Rock wool,80mm

Agitation type:Bottom agitation,With Frequency control,Power:0.75kw, Speed ratio: 1:43

Rack system:Thin rake blades,Hanging chain,With grain spent plate.

Filter plate:Milling sieve,with support at the bottom and unload handle;

Side spent-grain outlet,with guide plate below the outlet door.

Manhole type and diameter:All glass manhole,φ500mm

Chimney:600mm

Four stainless steel legs, with screw assembly to adjust leg height, the base plate with two fixed hole;

Fittings of the tun:2 CIP ballsLED lightPT-100 temperature probeOther matched valves

5bbl boil kettle and whirlpool tun features

Working volume:5BBLTotal volume:6BBL

Design temperature:Min:0℃ Max:100℃Design pressure:Atmosphere

Inner tank thickness:2.5mmOuter tank thickness:2mmSurface process of the tank:Brushed surface

Head type:Conical head

Insulation material and thickness:Rock wool,80mm

Steam jackets thickness:1.5mmPosition:Around middle cylinder and bottom cone

Side whirlpool tangent inlet

Manhole type and diameter:All glass manhole,φ500mm

Chimney:600mm

Four stainless steel legs, with screw assembly to adjust leg height, the base plate with two fixed hole;

Fittings of the tun:2 CIP ballsLED lightPT-100 temperature probeOther matched valves

Wort pump:-Type:3m3/h, 18m-Power:380V 1.5KW-With frequency conversion-Inlet size Ф38, outlet size Ф32-The material connected with wort is sanitary stainless steel 304-With waterproof shield

Filter pump:-Type:3m3/h, 18m-Power:380V 1.5KW-With frequency conversion-Inlet size Ф38, outlet size Ф32-The material connected with wort is sanitary stainless steel 304-With waterproof shield

Hot water pump:-Type:3m3/h, 18m-Power:380V 1.5KW-With frequency conversion-Inlet size Ф38, outlet size Ф32-The material connected with wort is sanitary stainless steel 304-With waterproof shield

Heat exchange plate:-Size:8㎡-Two stage cooling, 6 process;-Cold water inlet G1, cold water outlet Ф32 , wort inlet & outlet Ф32.

Pipe type hop filter:-Removable-Filter precise:0.1mm

Brewhouse Pipes:-Size:ISO:Φ38/Φ32-Single welded, double shaped

Aeration Assembly-With sight glass-Used on wort outlet of the heat exchanger-With thermometer

Survey Barrel-L=350mm

Sanchorometer-Size:10°,20°

Titanium bar-Filter precision: 0.45μm

Grain-out Rake-L=1500

Working platform-Punched-hole platform-With stairs and guardrail-Height and size will be designed according to the actual brewhouse size and the brewery place

Below is the main parameters of the 5bbl fermenters

▪Stainless steel dished head

▪Sanitary butterfly valves, beer sample valve,PVRV

▪Clamps and gaskets, pressure gauge

▪Interior shell: SUS 304 stainless steel, thickness 3mm

▪Exterior shell: SUS 304 stainless steel, thickness 2mm

▪Interior and exterior finish polished to a sanitary finish

▪Interior finish pickled and passivation

▪Dimple jacket cooling jackets

▪Exterior brushed polishing surface finish

▪Fully welded exterior shell

▪60 degree cone bottom, with an average of 25% head space

▪Rotating racking port

▪Side/Top manway door

▪Dual zone dimple cooling jackets (3 or more on larger tanks)

▪80mm Polyurethane insulation

▪CIP arm and spray ball with a molding technology

▪Sanitary tri-clamp connections

▪Upgrade drain port

▪Dry hop dosing port

All material in contact with product will be of Stainless Steel,304.Light glass made of glass. Pipe/Fitting standard will be designed according to your request ;All valves in contact with product will be of Hygienic Butter Valve Type ;All components and wire will be with CE marked ;Process connections will be designed according to your request.Sanitary screw couplings or Sanitary Tri-clamp ;Welds will be fully burned,shield gas will be used.With no pores,cracks.

If you are considering entering the brewing beer or craft beer industry. Whether it is investing in bars,breweries, restaurants, or small and medium-sized breweries, it is necessary to have a clear understanding of the requirements for beer brewing technology and equipment technology configuration. If you have any questions on the 5bbl beer brewing equipment for microbrewery, please communicate with professionals and manufacturers in detail. Shandong SENMO Machinery Co., Ltd., as a professional beer equipment production service provider, provides you with professional technical consultation in the early stage, and carries out equipment design, production, installation, commissioning and other services according to the requirements of beer brewing technology.

FAQ

Q1: What is 5BBL beer brewing equipment?

A1: 5BBL beer brewing equipment refers to a brewing system designed to produce beer in batches of 5 barrels, which is approximately 155 gallons or 586 liters. It's an ideal size for microbreweries looking to craft small to medium quantities of high-quality beer.

Q2: Is 5BBL brewing equipment suitable for a microbrewery?

A2: Yes, 5BBL brewing equipment is a popular choice for microbreweries. It allows them to produce a diverse range of beer styles while maintaining a manageable production scale.

Q3: What does the brewing equipment typically include?

A3: A typical 5BBL brewing equipment setup includes a mash tun, a boil kettle, and a whirlpool. These vessels are essential for mashing, boiling, and separating the wort from the hops and other solids.

Q4: How much beer can be produced per batch?

A4: With a capacity of 5 barrels, each batch can yield around 155 gallons or 586 liters of beer. The exact amount may vary depending on factors like recipe and brewing efficiency.

Q5: Can the equipment handle different beer styles?

A5: Yes, 5BBL brewing equipment is versatile and can accommodate a wide range of beer styles. Microbreweries can experiment with various recipes and create diverse offerings to cater to their customers' preferences.

Q6: Is the brewing equipment user-friendly for microbrewery staff?

A6: Many manufacturers design their equipment to be user-friendly and intuitive. Training sessions are often provided to ensure microbrewery staff can operate the equipment effectively.

Q7: What is the brewing process on 5BBL equipment like?

A7: The brewing process on 5BBL equipment generally involves mashing, boiling, cooling, fermenting, and packaging. Each step is carefully managed to create high-quality beer.

Q8: How long does a brewing cycle typically take?

A8: The duration of a brewing cycle can vary, but it usually takes several hours to complete mashing, boiling, and cooling. The overall time may also depend on the specific recipe and fermentation duration.

Q9: Can the brewing equipment be customized for specific needs?

A9: Yes, many manufacturers offer customization options to tailor the brewing equipment to the microbrewery's specific requirements. This can include vessel sizes, controls, and additional features.

Q10: What are the benefits of using 5BBL brewing equipment for a microbrewery?

A10: Using 5BBL brewing equipment allows microbreweries to produce a variety of high-quality beers, experiment with new recipes, cater to diverse tastes, and maintain a manageable production scale.

Q11: Is the brewing equipment suitable for limited distribution or on-site consumption?

A11: Yes, 5BBL brewing equipment is well-suited for both limited distribution and on-site consumption. Microbreweries can serve their freshly brewed beer to customers in their taproom and possibly distribute to local retailers or bars.

Q12: How can a microbrewery get started with 5BBL brewing equipment?

A12: Microbreweries interested in acquiring 5BBL brewing equipment can reach out to reputable brewing equipment manufacturers. They can discuss their specific needs and receive guidance on the equipment's features and integration into their microbrewery setup.

Q13: Does the brewing equipment require a specific amount of space?

A13: The amount of space required depends on the equipment's design and layout. Microbreweries should consider factors like the vessel sizes, utilities, and workspace when planning the installation.

Q14: Can the brewing equipment help a microbrewery attract more customers?

A14: Yes, brewing beer on-site with 5BBL equipment can be a significant draw for customers. It offers the authentic experience of freshly brewed beer and showcases the craft of brewing.

Q15: How does the 5BBL brewing equipment contribute to the microbrewery's identity?

A15: The brewing equipment becomes an integral part of the microbrewery's identity. It allows the microbrewery to create its own signature beers, experiment with flavors, and establish a reputation for crafting exceptional and distinctive brews.