How to do commercial beer brew

Before you buy commercial brewing equipment,it is very important to know how to do commercial beer brew properly.Below is an instruction of the beer brewing process using the beer equipment.

Step 1:Malt mill using the malt miller

In the first step, the superior Australian wheat is selected to be crushed with a malt grinder, which is conducive to the extraction and dissolution of materials, the dissociation of enzymes and the improvement of saccharification effect; Before mashing, add proper amount of water to wet the surface of barley malt 5-10 minutes in advance to meet the requirement of malt mashing powder, so that the grains can form a filter layer to facilitate wort filtration. During the crushing process, samples shall be taken at any time to check the malt crushing condition. The handwheel and feeding amount shall be adjusted appropriately according to the size of the malt powder. The coarse and fine grains shall have a certain proportion.

Special attention: barley malt should be ready to use, and should not be stored for a long time. When special malt is crushed, it shall not be moistened. According to the thickness of malt powder, the roll spacing and feeding amount shall be properly adjusted, and the proportion of coarse and fine grains shall be 1:2.5. At present, the malt miller on the market are divided into disc malt miller and roller malt miller.

Step 2:Mashing inside of the beer mash tun

The ratio of malt to water is 1:4. Feeding into the mash pot: start the mash tun to stir, open the valve of the grist case, put the crushed malt into the mash tun, mix evenly, and stop mixing when the temperature reaches the set temperature. Protein pause: when the temperature reaches the set temperature of 53 ℃, stop mixing and keep it for 20 minutes for protein decomposition. Saccharification: After the protein decomposition is completed, start the saccharifying pot to stir, turn on the steam for heating, and then raise the temperature to the set temperature (generally 66 ℃) at the rate of 1~1.5 ℃/min for saccharification. The saccharification time is about 30 minutes. Finally, it rises to 78 ℃ and is ready for filtration.

Step 3:Wort filtration inside of the beer lauter tun

Wort filtration and washing: put the mash that has stopped saccharification into the filter tank, clean the pipeline, pump and mash tun, and then start to reflux. After the reflux is clear, filter it to the saccharifying pot, and control the flow rate at two fifths of the full pot capacity per hour. When all the heated pipes are submerged and two centimeters upward, start heating to raise the temperature. After the layer of lees is exposed, start to wash the lees. The water for washing the lees is 20-25% of the original wort. After the water for washing the lees is added, stir it with a rake to fully mix the water with the lees. After being still for 10 minutes, start to reflow, start to filter after the reflow is clear, filter to the full pot, and stop filtering.

Step 4:Boiling inside of the kettle

After wort filtration, turn on the heating tube and start boiling. When wort boils, start timing. The boiling time is 60 minutes. The wort is always boiling; Control the final wort concentration. If the concentration does not meet the requirements within the specified time, it can be delayed appropriately. Add hops: the wort is boiled for 5 minutes, 30 minutes and 10 minutes before the end of boiling. Add bitter hops and fragrant hops respectively according to the formula.

★ Special attention: a. In the process of boiling, mixing must be started. b. After the hops are weighed, the original package shall be sealed and put into the refrigerator immediately to prevent oxidation.

Step 5:Whirlpool

After boiling, the wort will be whirled back for 3-5 minutes. After that, it will be left to precipitate for a period of time, and then the hot coagulates will be discharged for wort cooling. The duration of this process will also affect wort fermentation.

Step 6 :Wort cooling

After the completion of wort whirlpooling,slowly open the cooling water valve (the initial opening shall not exceed 1/4). When the wort temperature drops below 80 ℃, start the wort pump for circulating cooling. When the wort temperature drops below 30 ° C, turn off the wort pump, and then turn off the cooling water and coil valve.

Step 7 Fermentation process:

Fermentation tank cleaning and sterilization → inoculation → wort feeding → impurity removal → sugar measurement → pre fermentation → tank sealing → post fermentation → yeast treatment

This process determines whether the tank is sterile, whether the inoculation is free of bacteria, whether impurity removal is timed and quantified, whether the sugar measurement is accurate, whether the fermentation before tank sealing meets the standard, whether the post fermentation temperature and pressure control is accurate, and whether the taste is properly mastered, The differences are caused by different operators; In addition, the length of fermentation time will be affected by the amount of inoculation, environmental temperature and other factors.

Sugar measurement: take samples for sugar measurement the next day after feeding (it must be measured every day to observe the fermentation state)

a Treatment of fermentation beer: first discharge the impurities in the beer tube, take a measuring cylinder of fermentation liquor, repeatedly pour it with two cups for 100 times (the distance between cups shall not be less than 50cm) to remove the CO2 in the fermentation liquor, pour it into the measuring cylinder, and place it stably.

b. Measurement of sugar content: take a sugar meter with a measuring range of 0-10BX, slowly insert one end with mercury bag into wort, and the others are the same as the original wort concentration measurement method.

SENMO provide the whole beer brewing recipes for our clients and teach them hand by hand of how to do commercial beer brewing,beside of that,the following high-quality services will be obtained when purchasing SENMO beer equipment. We not only sell beer equipment, but also provide one-stop service, so that the equipment you buy can generate commercial value:

(1) We provide on-site equipment installation and commissioning services;

(2) We provide beer making technology training for free. The learning period is about 10 days until we learn it;

(3) Lifelong maintenance of brewing equipment and free upgrade of brewing formula;

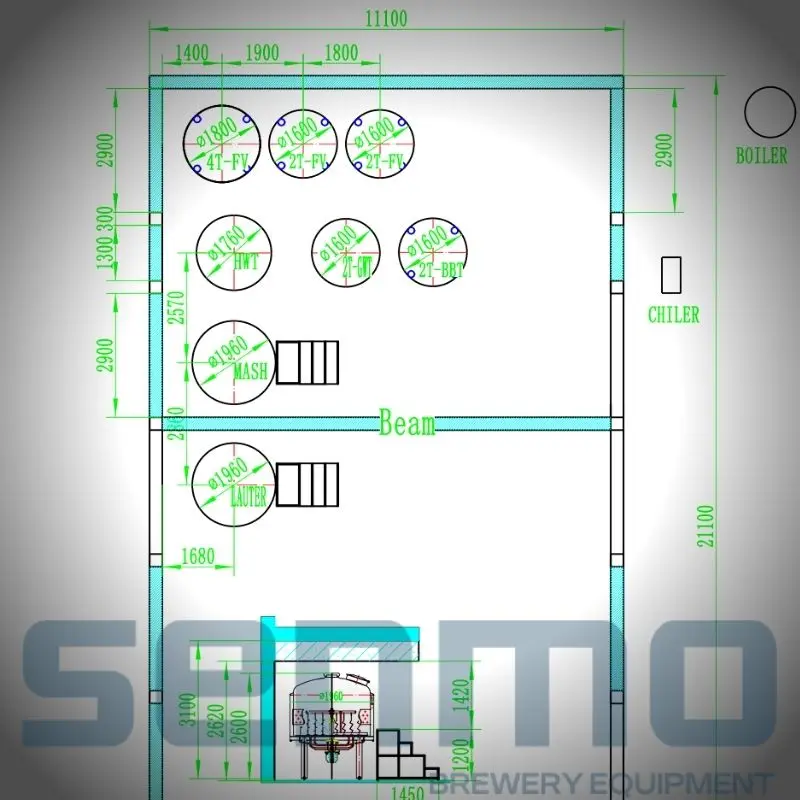

(4) After the site is selected, assist in the design of the floor plan of the store site, place beer equipment reasonably, and avoid repeated construction;