How to select beer equipment for your brewery

The selection of beer equipment mainly considers two aspects:

1. Technical configuration requirements for brewing process of equipment.

2. Equipment size and output requirements.

The output depends on the size of the brewhouse equipment and the daily mashing batch; And the size and quantity of fermentation tanks.

Relationship between beer brewing technology and equipment configuration

The brewing process of beer equipment mainly considers the matching of mashing process requirements and equipment function requirements. It mainly involves three aspects:

1. Mash process: one-temperature mashing or multi-temperature mashing.

2. The method of washing the spent grains: washing with hot water or with cold water (tap water).

3. Heating method: electric heating pipe heating, steam heating, or direct fire heating?

Electric heating tube heating or steam heating mainly involves cost and mashing process.

Electric heating pipe heating: install electric heating elements in the wort kettle, and directly heat through electric energy; Boil hot water and wort. Electric heating is suitable for "mash mixing method", but not for "heating by stages". Electric heating is mainly used to heat mash through hot water. Electric heating is not recommended for equipment above 1000L.

Steam heating: the outer side of the inner tank of the wort kettle is equipped with a steam jacket, and use steam boileris generat steam to heat the wort. (Type of steam generator: electric boiler, fuel boiler and gas boiler.)

Direct fire heating: there is a furnace under the kettle to burn natural gas. At present, direct-fire heating equipment mainly burns natural gas. In some places, the price of steam generators is extremely high. In order to reduce the cost of equipment procurement, direct-fired heating is used.

In terms of operation of electric pipe heating and steam heating, steam heating equipment is easy to clean and electric heating maintenance is time-consuming. Steam heating is recommended for brewhouse.

The electric heating pipe can only be used to heat mash (the electric heating pipe can burn hot water and boil wort), and it is not applicable to the step by step temperature rise method for saccharification. The maintenance of electric heating is more difficult than steam heating. Electric heating is local high temperature and uneven heating.

In terms of investment cost: electric tubes heating saves one boiler money than steam heating.

To sum up, the configuration requirements and process suggestions for purchasing small and medium-sized beer equipment are as follows:

1.Mash temperature heat up stage by stage. 2. Sparging with hot water. 3. Steam heating.

Size selection and yield calculation of beer brewing equipment

The output of beer brewing equipment depends on the type and size of brewhouse and the daily mashing batch; The size and quantity of fermentation tanks and the fermentation cycle of beer. Different equipment has different requirements for the size, height, water and electricity of the site.

(1) Type, size, brewing batch and yield calculation of saccharification equipment

Main types of brewhouse system of small and medium-sized beer equipment:

Two-vessel brewhouse (Mash/lauter tun+Kettle/whirlpool tun);

Combined three-vessel brewhouse (Mash tun/Whirlpool tank+Wort kettle);

Two-vessel brewhouse (Mash/lauter tun+Kettle/whirlpool tun)+hot water pot;

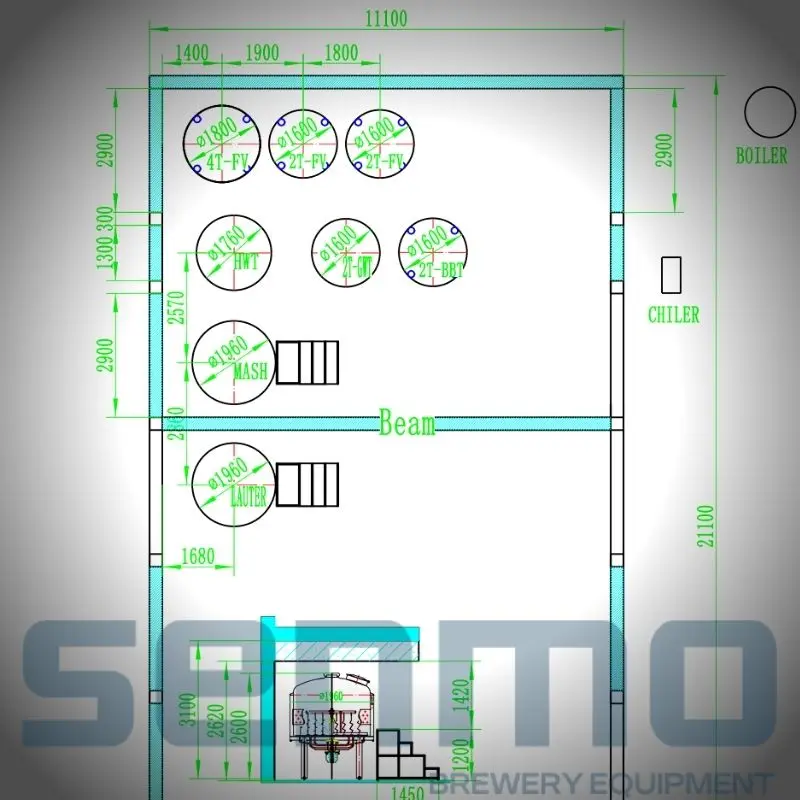

Three-vessel brewhouse (Mash tun+lauter tun+kettle/whirlpool tun)+hot water pot;

Four-vessel brewhouse (Mash tun+lauter tun+kettle+whirlpool tun)+hot water pot.

The brewhouse finish one batch brewing takes 7-8 hours from malt crushing to wort entering the fermentation tank. Homebrew equipment and craft beer brewing equipment used in hotels, bars, microbreweries and restaurants are generally of 500L or 1000L, two-vessel brewhouse and hot water tank. One or two batches of wort brewing a day. In consideration of factors such as labor force and labor intensity, there is actually one batch per day.

The large industry beer equipment is a multi-vessel brewhouse equipment, which is produced in shifts and continuously feeds and mashing in multiple batches. The interval between each feeding is 3-4 hours. Three vessels can be saccharified and brewed in three batches at 24 hours a day. Four vessels can be saccharified and brewed in four batches at 24 hours a day.

The size of brewhouse equipment and the capacity of the highest brewing batches determine the maximum capacity of the equipment. For example:

2000L two-vessel brewhouse can reach a maximum of 4000L of daily output.

2000L three-vessel brewhouse can reach up to 6000L of daily output.

2000L of four-vessel brewhouse can reach up to 8000L of daily output.

Investment suggestions: The size and type of saccharification equipment should be considered according to the actual brewery site, capacity requirements and investment budget. The larger the brewhouse equipment, the higher the energy consumption and the higher the investment cost. However, the cost of later brewhouse expansion transformation is also relatively high. It can be considered that big brewhouse capacity for the first step.

2) Size and quantity of fermentation tanks.

Daily output=volume of fermentation tank × Number of fermentation tanks ÷ beer fermentation time

The volume of brewhouse equipment and fermentation tank can be 1:1,1:2... The volume of fermentation tank is a multiple of brewhouse. Briefly, within 24 hours, the wort will be filled into the fermentation tank for fermentation.

The fermentation cycle of Ale and wheat beer is 1-2 weeks, and lager beer is 2-4 weeks. The average fermentation period is 12 days. Take 500L fermentation tank as an example.

Namely, daily output (250L)=volume of fermentation tank (500L) × Number of fermentation tanks (6) ÷ beer fermentation time (12 days

Investment suggestions: small beer equipment mainly refers to micro beer equipment and craft beer equipment used in hotels, bars, restaurants and microbreweries. The fermentation tank is mainly 500L and 1000L. The number of fermentation tanks in the early stage can be reduced to about 6. It is relatively easy to expand production and add fermentation tanks in the later stage.

The investment and construction of small and medium-sized breweries is also based on the construction by stages. In this way, the pressure of initial capital investment and market sales is relatively small. After the production is stable and the market is expanded, prepare for expansion.

Beer brewing has a variety of processes, and beer equipment belongs to non-standard equipment. At present, there is no unified national standard, and there is no unified industry standard, which is the enterprise's own standard. This is an outline explanation and explanation of the whole system based on the market concerns and our professional experience.

If you are considering entering the brewing beer or craft beer industry. Whether it is investing in bars,breweries, restaurants, or small and medium-sized breweries, it is necessary to have a clear understanding of the requirements for beer brewing technology and equipment technology configuration. If you have any questions, please communicate with professionals and manufacturers in detail. Shandong SENMO Machinery Co., Ltd., as a professional beer equipment manufacturer, provides you with professional technical consultation in the early stage, and carries out equipment design, production, installation, commissioning and other services according to the requirements of beer brewing technology.