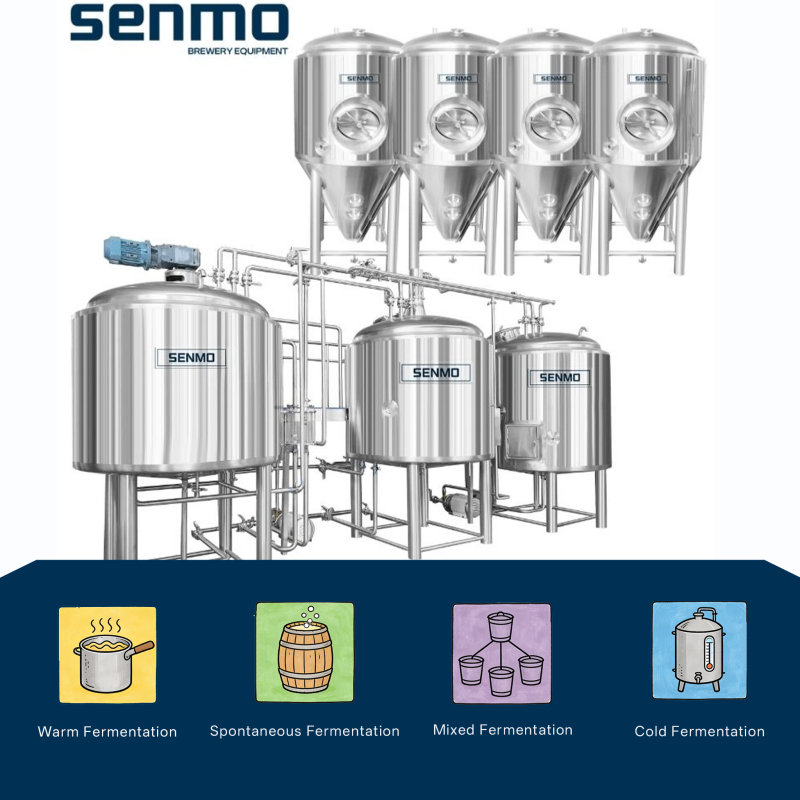

Microbrewery 3000L conical beer fermentation tank

This is our 3000L conical beer fermenters for microbreweries.Nowadays, most breweries use conical fermenters to ferment beer. The 3000L tank body has its own cooling device, which can easily control the fermentation temperature; The conical tank is convenient for operation, labor saving, cleaning and yeast recycling.

The "One tank fermentation" means that the whole fermentation process is carried out in one conical tank, without strict division of pre fermentation and post fermentation, and the production time is shorter than that of the traditional process.

Next, we will introduce the operation method of the conical fermentation tank in detail.

Common Lager Fermentation Process Operation

The yeast inoculation temperature of Lager fermentation is generally 6-10 ℃, and the maximum fermentation temperature is 12 ℃. The time from inoculation to can sealing is about 5-7 days. When the sugar content drops to 3.8-4.2 ° P, seal the can. Keep the tank pressure 0.12MPa after the pressure rises, and keep it for 5-7 days after the temperature rises to 12 ℃ to reduce diacetyl.

Then cool down to 5 ℃ for one day, and then cool down to 0 ℃. The cooling rate is different in different stages. In the 12 ℃ - 5 ℃ stage, the cooling rate is 0.3 ℃/h, and in the 5 ℃ - 0 ℃ stage, the cooling rate is 0.1 ℃/h. The ripening stage of lager fermentation is generally 5-7 days

Common Ale fermentation process operation

The inoculation temperature of Al fermentation is generally 16-18 ℃, which is higher than that of Lager, and its maximum fermentation temperature can reach 20-23 ℃. The time from inoculation to tank sealing is about 1-1.5 days, which is short. Similarly, when the sugar content drops to 3.8-4.2 ° P, seal the tank. After the pressure rises, keep the tank pressure at 0.12-0.15MPa. After the temperature rises to 20 ℃, keep the tank pressure for 5-6 days, and reduce diacetyl.

The cooling process of Al fermentation is also reduced to 5 ℃ for one day and then to 0 ℃. In the 20 ℃ - 5 ℃ stage, the temperature shall be decreased at the rate of 0.3 ℃/h, and in the 5 ℃ - 0 ℃ stage, the temperature shall be decreased at the rate of 0.1 ℃/h. The beer will mature after 5-7 days of storage at low temperature.

Side manhole+Beer sample valve port+Temperature blind tube+Cooling pipe connection port

Beer fermentation process critical control points

Yeast addition

(Dry yeast)

-Ale 30-50g/100L, Lager 20-80g/100L.

Temperature

Controlling different fermentation temperature has its own advantages and disadvantages. When low-temperature fermentation is adopted, yeast produces less by-products during fermentation, beer tastes better, foam is in good condition, but the fermentation time is long; With high-temperature fermentation, the fermentation speed of yeast is fast, the fermentation time is short, and the utilization rate of equipment is high, but more by-products are generated, and the beer taste is poor.

Lager is generally fermented at 8-12 ℃, and Ale is 16-20 ℃. In addition, pay attention to the temperature control in winter

Hygiene

Hygiene plays a vital role in beer quality, and aseptic operation should be paid attention to when inoculating yeast or dry dropping hops. The hands shall be disinfected when opening the manhole, and the outer package around the manhole and inoculated with yeast shall also be cleaned and disinfected. Use 75% alcohol as disinfectant and spray it with a watering can. Pay attention to safety. Do not use open fire during disinfection.

Fermentation pressure

The fermentation pressure of lager beer is generally controlled at 0.12MPa, and that of Ale beer is 0.15MPa. The fermentation pressure mainly depends on the final taste requirements of the product. The higher the pressure is, the lower the temperature of the liquor is, and the more fully the carbon dioxide is dissolved, the stronger the mouthkilling power of beer will be, and the foam will be rich and lasting.

Beer sample valve+CO2 charging device+Beer rotary racking arm+Temperature sensor

The fittings on the tanks can be added or took out as per your requirements,also,the connection method can be changed,there are Tri-clamp connection way,Dairy coupler connection way and Welding type. The connection type has ISO,DIN,SMS...all kinds of standard to be optional.

Temperature blind tube+Port inside of fermenter+Beer outlet+Interior of the fermenter

As an experienced beer equipment manufacture,SENMO provide tailored beer fermenters for worldwide breweries.If you have plan to expand your beer production capacity,adding extra fermenters is one of the options.Please send us inquiry of the fermenters or beer unitanks which you want,our sales engineer will send you a detailed quote! Cheers!