Microbrewery 30BBL brewing equipment US

In the ever-evolving landscape of craft beer, precision, innovation, and quality are the hallmarks of success. SENMO, a renowned brewing equipment manufacturer, has captured the essence of craft brewing with its 30BBL microbrewery equipment designed exclusively for the US market.

SENMO's 30BBL brewing equipment is a testament to the art and science of brewing. Crafted with precision and finesse, it empowers microbreweries across the United States to create exceptional beer that resonates with connoisseurs and beer enthusiasts alike.

This is microbrewery 30BBL beer brewing equipment made by SENMO Company,the whole brewing equipment includes the following main equipment:

30bbl mash tun with grist hydrator

30bbl lauter tun with rake knives and sieve plate

30bbl wort kettle with steam jackets around the tank body and bottom cone

30bbl whirlpool tun with tangent whirlpool inlet

60bbl hot water tank

60bbl cold water tank

90bbl brewing water tank

Wort pumps and water pumps

Plate heat exchanger

Big operation platform

Wort pipes and valves

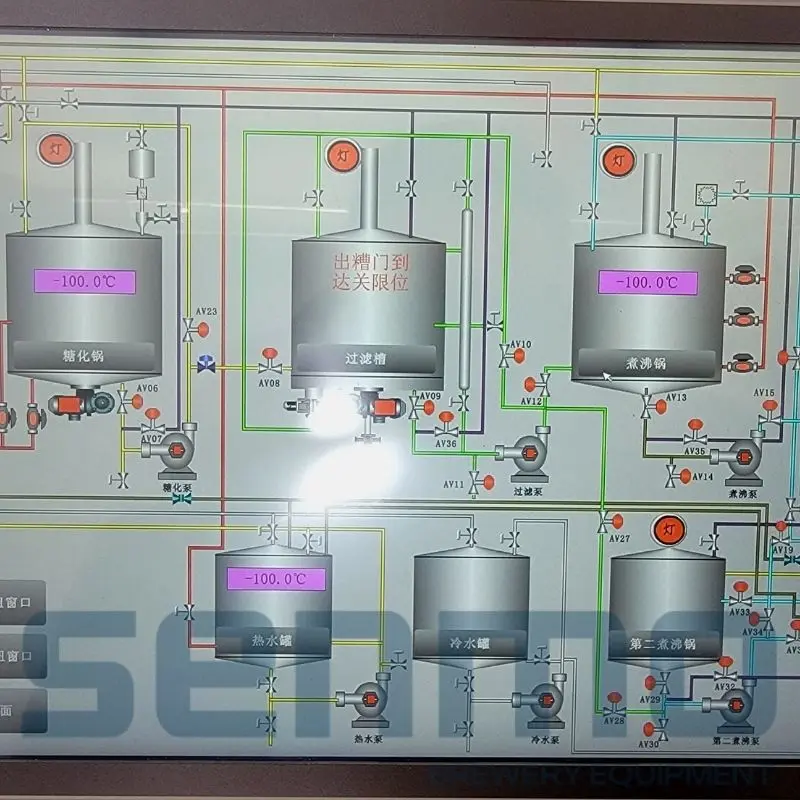

PLC control cabinet

The design of beer brewing equipment details is rigorous, so as to maximize the utilization of brewing materials and reduce equipment energy consumption.The brewhouse tank plates and accessories are made of international standard SUS304 stainless steel; Our factory use laser cutting and argon shielded welding during the tank production,all vessels' internal do centralized pickling and passivation, accuracy ≤ 0.4 μ m;The brewhouse has high precision temperature sensor, pressure sensor, liquid level sensor and other components, Siemens PLC control, program input, multi process formula storage and setting, simple operation;Accessories of auxiliary machines are selected from domestic and foreign first-line brands, which are CE/UL certified.

Steam jackets around the 30bbl mash tun and 30bbl wort kettle: working pressure 0.15MPa, test pressure 0.4MPa, super large heating area around the tank body and bottom cone, heating rate 1-1.2 ℃/min, automatic temperature control; The mash tun frequency conversion mixing has strong convection, and the grains and water are mixed evenly, supporting high wort plato beer brewing process;

Variable frequency automatic lifting plough cutter for the 30BBL lauter tun, milling sieve plate is removable, the gap is 0.7mm, opening rate greater than 17%, multiple supporting points at the sieve plate bottom, and there is backwashing device to reduce sanitary dead angle; Optional bottom grain discharging and automatic grain discharging devices are used to uniformly transport the spent grains to the outdoor spent grain tank. The whole wort filter process is closed and efficient;

The 30BBL wort boiling kettle is equipped with forced circulation to support boiling under pressure, ensuring 8-12% boiling strength, improving the utilization rate of heat energy, and can optionally be equipped with condensate recovery device;

The 30BBL wort whirlpool tank circulates tangentially, and the high and low liquid level discharge ports are equipped with baffles for hot solidified substances and hops decomposition substances;

Key Features

Optimized Capacity: The 30BBL capacity strikes a balance between production volume and craft quality. It caters to the growing demand for unique and high-quality brews while maintaining the artisanal touch.

Premium Materials: SENMO's commitment to excellence is evident in its choice of premium materials. From stainless steel tanks to precision valves and fittings, every component is selected to ensure durability, hygiene, and the preservation of flavors.

Cutting-Edge Technology: The brewing process is an intricate dance of time, temperature, and ingredients. SENMO's equipment is equipped with state-of-the-art temperature control systems, ensuring that every brew is crafted with precision.

User-Friendly Interface: Microbrewers appreciate the intuitive interface that simplifies the brewing process. SENMO's equipment empowers brewers to focus on their craft, with technology taking care of the rest.

Energy Efficiency: SENMO understands the importance of sustainability in today's brewing industry. Their equipment is designed for energy efficiency, helping microbreweries reduce their carbon footprint while saving on operational costs.

Tailored for Excellence

SENMO's 30BBL brewing equipment is not just a piece of machinery; it's a canvas for brewers to create their masterpieces. Its versatility allows for a wide range of beer styles, from ales to lagers, stouts to IPAs, and beyond. The equipment adapts to the brewer's vision, ensuring that each batch is a work of art.

Support and Service

SENMO's commitment to excellence extends beyond the equipment itself. They offer comprehensive support and service, ensuring that microbreweries have the resources they need to thrive. From installation and training to maintenance and troubleshooting, SENMO is a trusted partner on the brewing journey.

Crafting Tomorrow's Classics

In a world where craft beer continues to capture hearts and palates, SENMO's 30BBL microbrewery equipment is a beacon of craftsmanship and innovation. It empowers microbreweries across the United States to create beers that tell a story, evoke emotions, and become tomorrow's classics. With SENMO, the future of craft brewing is not just bright; it's perfectly brewed.

If you want to learn more about the features of the 30bbl brewing equipment,please send us inquiry,our sales engineer can send you a detailed proposal.Below is the services which we can provide for you:

Sales consulting. SENMO provide fast, professional and detailed beer brewery equipment configuration list according to customer requirements.

Brewery technical design. According to the concept of customization, put forward design suggestions, integrate customer requirements, issue beer brewing process flow diagrams,micro brewery floor plans,machinery, electrical and other drawings, draw 3D drawing, and provide one-to-one tracking services.

Brewery equipment processing and manufacturing. Strictly implement the requirements of beer equipment design drawings, follow the IOS9001 quality management system, strictly control the quality of all links, and provide tanks test records of plates, welding, polishing, pressure, etc. for filing.

Brewery plant delivery and installation. The professional brewery project construction team conducts on-site installation, commissioning and training to ensure accurate delivery for use and continuous tracking maintenance.

FAQ

1. What is the brewing capacity of SENMO's 30BBL microbrewery equipment?

SENMO's 30BBL brewing equipment is designed for a 30-barrel brewing capacity, making it suitable for microbreweries looking to produce high-quality craft beer in moderate quantities.

2. What materials are used in the construction of SENMO's brewing equipment?

SENMO uses premium stainless steel for the construction of their brewing equipment, ensuring durability, hygiene, and the preservation of beer flavors.

3. Does SENMO offer customization options for their 30BBL brewing equipment?

Yes, SENMO understands that every microbrewery may have unique requirements. They offer customization options to tailor the equipment to the specific needs and preferences of individual brewers.

4. How user-friendly is SENMO's 30BBL brewing equipment?

SENMO's equipment is designed with an intuitive interface that simplifies the brewing process. Brewers can focus on their craft, with the technology taking care of operational tasks.

5. Is the equipment energy-efficient?

Yes, SENMO places a strong emphasis on sustainability and energy efficiency. Their 30BBL brewing equipment is designed to reduce energy consumption, helping microbreweries lower their environmental footprint and operational costs.

6. What type of support and service does SENMO provide for their equipment?

SENMO offers comprehensive support and service, including installation, training, maintenance, and troubleshooting. They are dedicated to ensuring that microbreweries have the resources they need for success.

7. Can SENMO's 30BBL brewing equipment accommodate various beer styles?

Yes, the equipment is versatile and can accommodate a wide range of beer styles, including ales, lagers, stouts, IPAs, and more. Brewers can experiment and create diverse beer offerings.

8. Is SENMO a trusted partner for microbreweries in the United States?

Yes, SENMO is a reputable and trusted manufacturer in the brewing industry. Their equipment is designed to meet the highest quality standards and empower microbreweries to craft exceptional beers.

9. What sets SENMO's 30BBL brewing equipment apart from others in the market?

SENMO's equipment is known for its precision, premium materials, energy efficiency, and user-friendliness. It offers microbreweries the tools they need to craft high-quality beer with consistency.