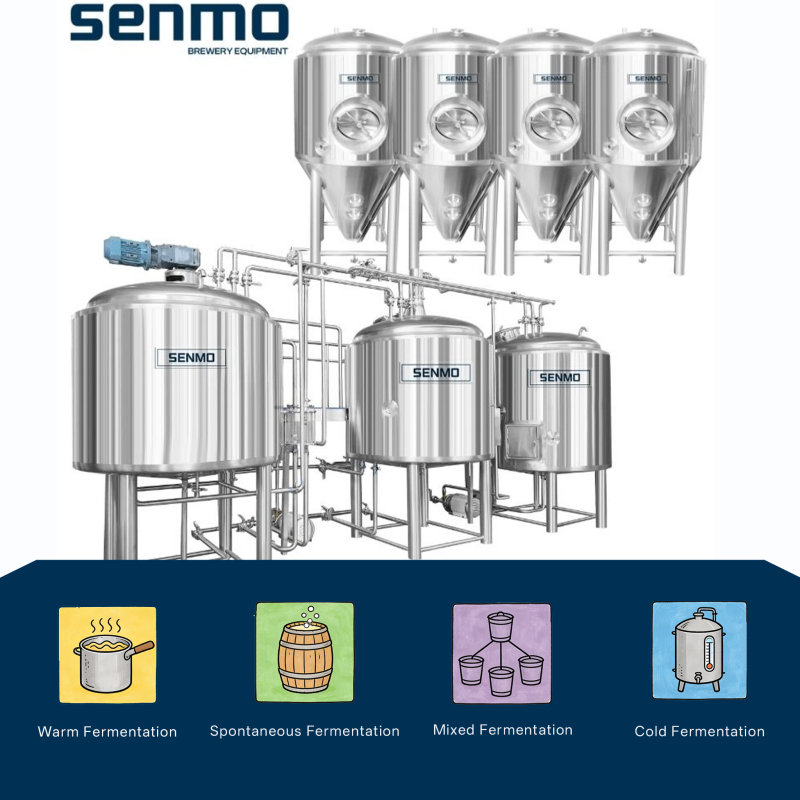

Microbrewery 30HL 3000L 4-vessel brewhouse system

543319.webp)

This is our microbrewery 3000L 4-vessel brewhouse system.The whole brewing system consist of the following equipment:

3000L mash tun with malt hydrator

3000L lauter tun with automatic spent grain

3000L wort kettle with inner heater

3000L whirlpool tun with tangent whirlpool inlet

Wort pump,mash pump

Plate heat exchanger

Wort pipes and valves

Hop adding tank

Wort grant tank

Operation platform

The calculation of beer brewing equipment details is rigorous, so as to maximize the utilization of brewing materials and reduce equipment energy consumption.The brewhouse tank plates and accessories are made of international standard SUS304 stainless steel; Our factory use laser cutting and argon shielded welding during the tank production,all vessels' internal do centralized pickling and passivation, accuracy ≤ 0.4 μ m;

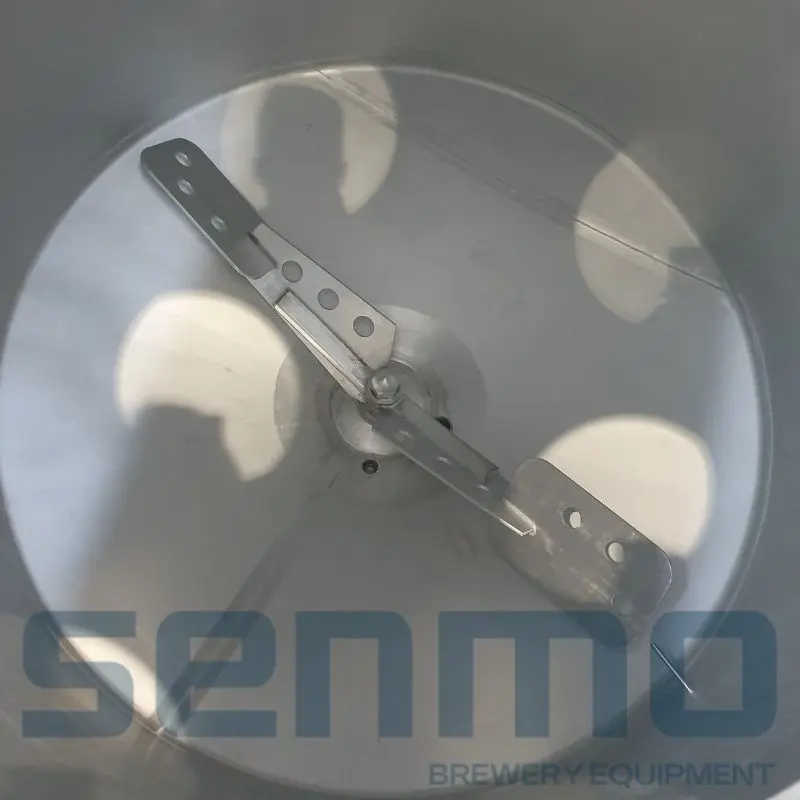

Steam jackets around the 3000L mash tun and 3000L wort kettle: working pressure 0.15MPa, test pressure 0.4MPa, super large heating area around the tank body and bottom cone, heating rate 1-1.2 ℃/min, automatic temperature control; The mash tun frequency conversion mixing has strong convection, and the grains and water are mixed evenly, supporting high wort plato beer brewing process;

Variable frequency automatic lifting plough cutter for the 3000L lauter tun, removable milling sieve plate, spacing 0.7mm, opening rate greater than 17%, multiple supporting points at the sieve plate bottom, and backwashing device to reduce sanitary dead angle; Optional bottom grain discharging and automatic grain discharging devices are used to uniformly transport the grains to the outdoor wheat grain tank. The whole wort filter process is closed and has strong timeliness;

The 3000L boiling kettle is equipped with forced circulation to support boiling under pressure, ensuring 8-12% boiling strength, improving the utilization rate of heat energy, and can optionally be equipped with condensate recovery device;

The 3000L wort whirlpool tank circulates tangentially, and the high and low liquid level discharge ports are equipped with baffles for hot solidified substances and hops decomposition substances;

Hot water flowmeter+Malt hydrator+Steam safety valve+Motor reducer

The brewhouse has high precision temperature sensor, pressure sensor, liquid level sensor and other components, Siemens PLC control, program input, multi process formula storage and setting, simple operation;Accessories of auxiliary machines are selected from domestic and foreign first-line brands, which are CE/UL certified.

3000L beer brewing equipment for medium-sized breweries

3000L beer brewing equipment is typically used in medium-sized breweries and can produce a significant amount of beer per batch. The equipment usually consists of a brewhouse, fermenters, and a beer conditioning system.

The brewhouse is the heart of the brewing process and includes vessels such as a mash tun, a lauter tun, a brew kettle, and a whirlpool. The mash tun is where the malted barley is mixed with water to create a mash, which is then transferred to the lauter tun where the sugars are extracted. The wort is then boiled in the brew kettle, and hops are added at various stages to add flavor and bitterness. Finally, the wort is transferred to the whirlpool, where solids are separated from the liquid.

After the brewing process is complete, the wort is transferred to fermenters, where yeast is added to begin the fermentation process. The beer will remain in the fermenters for several days to several weeks, depending on the desired flavor profile and alcohol content. Once fermentation is complete, the beer is transferred to a beer conditioning system, where it is carbonated and aged before being packaged for distribution.

When selecting 3000L beer brewing equipment, it's important to consider factors such as the type of beer you plan to produce, the amount of space you have available, and your budget. It's also important to choose equipment from a reputable manufacturer with a proven track record of producing high-quality brewing equipment.

The price of the 3000L 4-vessel brewhouse is different because of various configuration.If you want to buid brewery with such capacity brewing equipment,please send us your requirements on it,such as the heating way of the brewhouse,the quantity of the fermenters,your brewery layout drawings...our sales engineer can send you a formal quote for your reference.Cheers!

927.webp)