New Zealand, known for its stunning landscapes and vibrant culture, has also earned a reputation for its thriving craft beer scene. As the demand for unique and high-quality brews continues to grow, microbreweries across the country are at the forefront of this brewing renaissance. At the heart of these artisanal creations lies cutting-edge commercial brewing equipment, and we are proud to be a trusted supplier for New Zealand's brewing industry.

Microbrewery 30HL 3000L commercial brewing equipment New Zealand

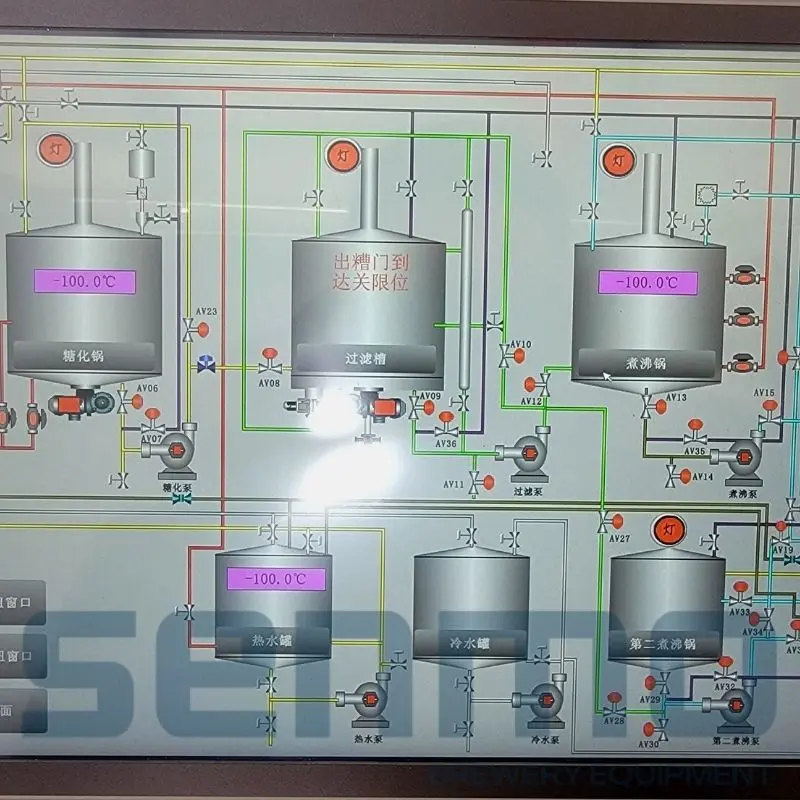

This is our microbrewery 3000L beer brewing equipment for the New Zealand market,the whole brewery plant is fully automatic control.Below is the main list of the 3000L brewing system:

-3000L mash tun with grist hydrator

-3000L lauter tun with automatic spent graint exhaust device and with grain sparging coil

-3000L wort kettle with steam jackets around the tank body and bottom cone

-3000L whirlpool tun with tangent whirlpool inlet

-6000L hot water tank

-6000L cold water tank

-10000L glycol water tank

-Wort pumps and water pumps

-Plate heat exchanger

-Wort pipes and vlaves

-Wort grant tank

-Hop filters and hop back tank

-Big operation platform

The design of beer brewing equipment details is rigorous, so as to maximize the utilization of brewing materials and reduce equipment energy consumption.The brewhouse tank plates and accessories are made of international standard SUS304 stainless steel; Our factory use laser cutting and argon shielded welding during the tank production,all vessels' internal do centralized pickling and passivation, accuracy ≤ 0.4 μ m;

Steam jackets around the 3000L mash tun and 3000L wort kettle: working pressure 0.15MPa, test pressure 0.4MPa, super large heating area around the tank body and bottom cone, heating rate 1-1.2 ℃/min, automatic temperature control; The mash tun frequency conversion mixing has strong convection, and the grains and water are mixed evenly, supporting high wort plato beer brewing process;Variable frequency automatic lifting plough cutter for the 4000L lauter tun, milling sieve plate is removable, the gap is 0.7mm, opening rate greater than 17%, multiple supporting points at the sieve plate bottom, and there is backwashing device to reduce sanitary dead angle; Optional bottom grain discharging and automatic grain discharging devices are used to uniformly transport the spent grains to the outdoor spent grain tank. The whole wort filter process is closed and efficient;The 3000L wort boiling kettle is equipped with forced circulation to support boiling under pressure, ensuring 8-12% boiling strength, improving the utilization rate of heat energy, and can optionally be equipped with condensate recovery device;The 3000L wort whirlpool tank circulates tangentially, and the high and low liquid level discharge ports are equipped with baffles for hot solidified substances and hops decomposition substances;

The brewhouse has high precision temperature sensor, pressure sensor, liquid level sensor and other components, Siemens PLC control, program input, multi process formula storage and setting, simple operation;Accessories of auxiliary machines are selected from domestic and foreign first-line brands, which are CE/UL certified.

Our factory use laser cutting and argon shielded welding during the tanks' production, the internal of the tanks commonly do pickling and passivation, the surface accuracy ≤ 0.4 μ m;The fermenters and bright tank has polyurethane foam insulation,thickness is 80mm;There is dimple cooling jackets around the tank body and bottom cone,the test pressure is 0.4MPa; The working pressure of the tank is 0.15 MPa, and the test pressure is 0.4 MPa; Our factory do water pressure test to all of the fermenters and bright tanks,the test period is 48hours.The strictly test and inspection make sure the tanks inside,the dimple jackets and pipe ports has no leakage when the fermenters arrives in our clients' brewery.The following fittings are matched with the fermenters:

-Mechanical pressure regulating valve

-Beer sample valve

-Breath valve

-Thermometer

-Hops dosing port

-Temperature sensor

-Beer rotary pipe

-Drain outlet

-CIP ball and CIP arm

-CO2 carbon stone

The connection of the fittings can be tri-clamp,diary couplers and other connection way you want.Meanwhile,if you need other fitings or port on the fermenters,you can tell us and we do the special design for you.

The price of the microbewqwey 3000L beer brewing equipment is different because of various configuration.If you want to buid brewery with such capacity brewing equipment,please send us your requirements on it,such as the heating way of the brewhouse,the quantity of the fermenters,your brewery layout drawings...our sales engineer can send you a formal quote for your reference.Below is the services which we provide for you:

Sales consulting. SENMO provide fast, professional and detailed beer brewery equipment configuration list according to customer requirements.

Brewery technical design. According to the concept of customization, put forward design suggestions, integrate customer requirements, issue beer brewing process flow diagrams,micro brewery floor plans,machinery, electrical and other drawings, draw 3D drawing, and provide one-to-one tracking services.

Brewery equipment processing and manufacturing. Strictly implement the requirements of beer equipment design drawings, follow the IOS9001 quality management system, strictly control the quality of all links, and provide tanks test records of plates, welding, polishing, pressure, etc. for filing.

Brewery plant delivery and installation. The professional brewery project construction team conducts on-site installation, commissioning and training to ensure accurate delivery for use and continuous tracking maintenance.

We are proud to play a role in New Zealand's craft beer renaissance by providing microbreweries with the tools they need to craft exceptional beer. Our 30HL (3000L) commercial brewing equipment is a testament to our commitment to quality, innovation, and collaboration. As New Zealand's microbreweries continue to create unique and outstanding brews, we look forward to being a part of their journey, helping them raise their glasses to the future of craft beer in this beautiful land.

FAQ

1. What is the capacity of the 30HL (3000L) commercial brewing equipment?

Our 30HL system has a brewing capacity of 3000 liters, making it ideal for microbreweries looking to produce larger batches of craft beer.

2. Is this equipment suitable for both startup microbreweries and established breweries in New Zealand?

Yes, our equipment is designed for both startup microbreweries and established breweries. It offers scalability to accommodate growing production needs.

3. Can I customize the brewing equipment to match my specific brewing style or recipe?

Absolutely! We offer customization options to tailor the equipment to your specific brewing requirements, allowing you to craft a wide range of beer styles.

4. What types of beer can I produce with this equipment?

Our brewing equipment is versatile and suitable for producing various beer styles, including ales, lagers, stouts, IPAs, and more.

5. Does the equipment include fermentation tanks?

Yes, our brewing equipment packages can include fermentation tanks, and we can provide options to match your fermentation needs.

6. Is technical support available for installation and setup?

Yes, we provide comprehensive technical support, including installation, setup, and training, to ensure a smooth brewing process.

7. How energy-efficient is the equipment?

Our brewing equipment is designed with energy efficiency in mind, helping you minimize operational costs and reduce your environmental footprint.

8. Can I expand my brewing capacity with this equipment in the future?

Yes, our equipment is designed for scalability, allowing you to expand your brewing capacity as your business grows.