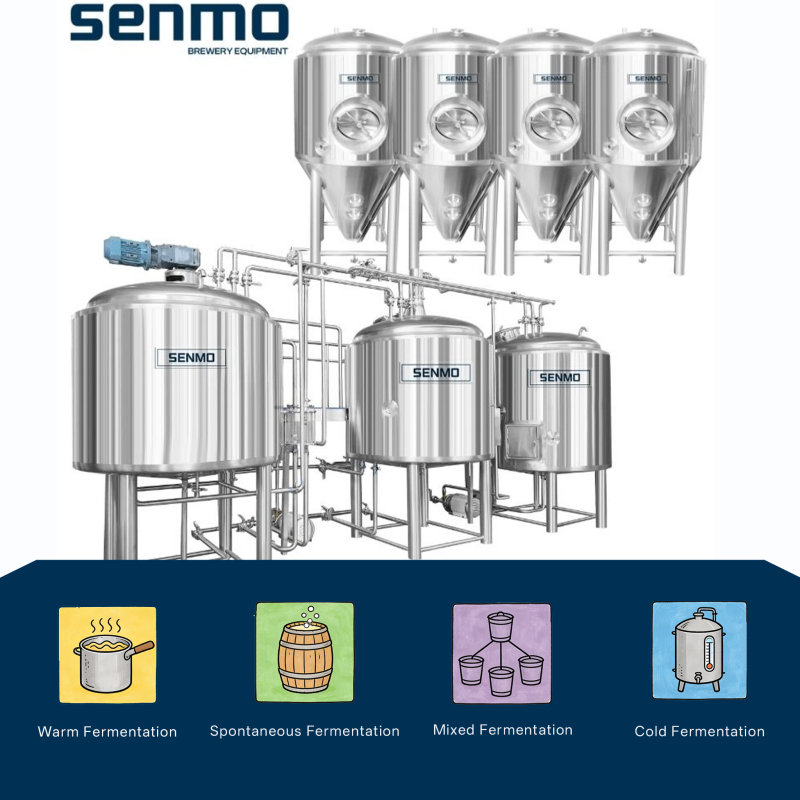

Microbrewery 400L beer brewing equipment

It is our 400L two-vessel brewhouse system with 800L hot water tank.The whole brewing equipment is made of SU304,and the equipment layout is designed according to our client's brewery site space.It is covers just 10m2 and the height is 2.8m.The 400L brewhouse system consist of the the following beer device:

400L mash/lauter tun with heating function

400L wort kettle/lauter tun with heating function

800L hot water tank with heating function

5M2 double-stage plate heat exchanger

Wort pump and hot water pump

Stainless steel operation platform

Glass wort grant tank

Stainless steel wort pipes and valves

Mash tun agitator+Lauter rake knife+Separate wort out and drain outlet+Steam coil inside of HWT

There are two kinds of mashing methods:

1. Mixing method: simply speaking, it is to make the mash temperature required for saccharification by adding hot water during malt saccharification.

2. Stage by stage heating method: The mash is heated directly to reach the temperature required for saccharification stage by stage.

This 400L mash tun is designed as per the 2nd mashing way.With steam jackets around the tun,it can heat up the temperature to what your brewing needed.

Heating mode of beer cooking equipment: electric heating tube (electric heating for short), steam heating, direct fire heating. Electric heating tube heating and steam heating determine whether to use steam generator. It mainly involves cost and saccharification process.

Spent grain door+Electric elements cabinet+Wort pipe+Pumps

The beer brewing equipment and hot water tank can be special designed as per your special requirement,the selection of beer equipment mainly considers two aspects:

1. Technical configuration requirements for brewing process of equipment.

2. Equipment size and output requirements.

The output depends on the size of the brewing equipment, the daily batch of mash feed, and the size and quantity of fermentation tanks.

The relationship between wort mash process and equipment configuration of beer brewing mainly involves the following three aspects:

1. Mashing process: boiling method or leaching method (generally mashing method and stage by stage heating in the leaching method).

2. Heating method: the equipment is steam heating, electric heating tube heating (referred to as electric heating), and direct fire heating.

3. How to wash the spent grains: hot water or cold water (tap water)?

Wort grant tank+Yeast adding tank+Hop back tank+Operation platform

If you are clear of the above questions before choose the beer equipment,then you can ask the quotes from the beer equipment manufactures. As a professional brewery equipment supplier in China,our company not only can provide you with a top quality equipment but alos a good offer! Cheers!