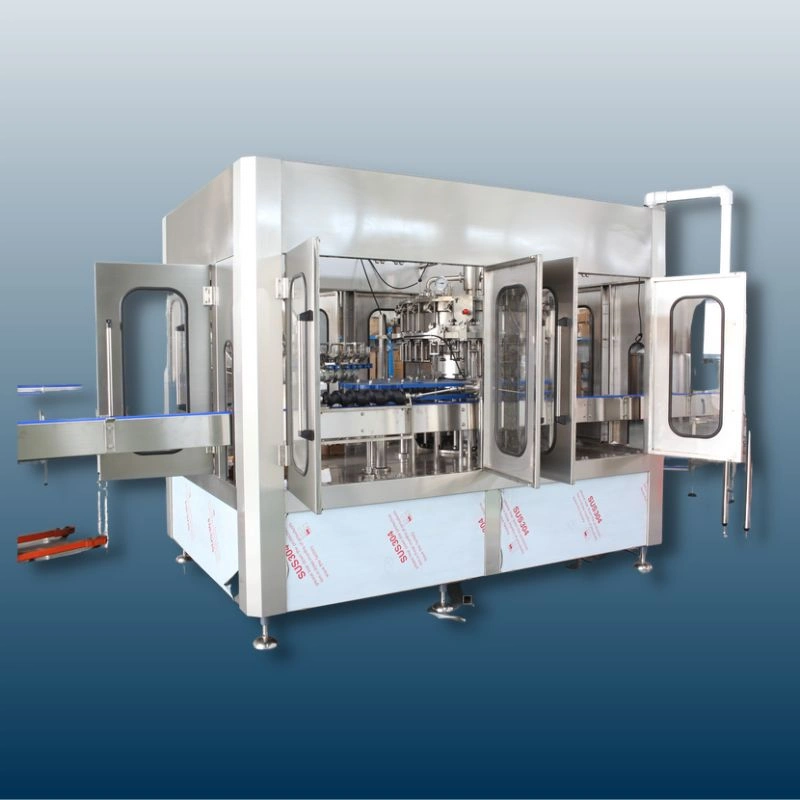

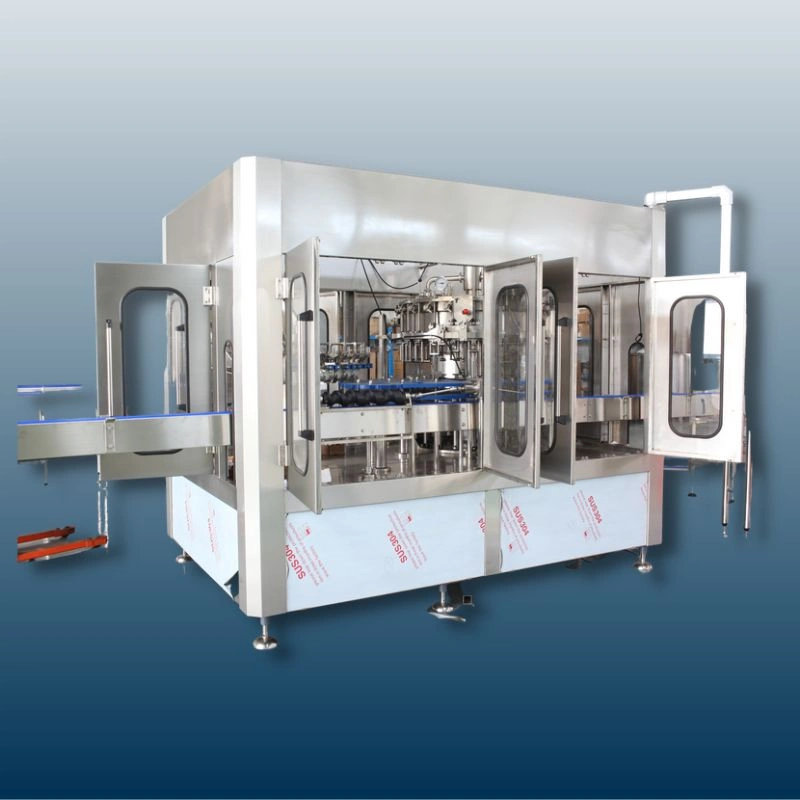

Beer bottling is an essential process in the beer production industry. It ensures that the beer is packaged and ready for sale to the consumers. However, manual beer bottling can be time-consuming and inefficient, especially when dealing with large quantities. That's where the automatic beer bottling machine comes in. This machine is designed to streamline the beer bottling process, making it faster and more efficient. 1000-1200BPH is the output of this beer bottling equipment.

Specifications

The automatic beer bottling machine is a high-speed machine that can fill up to 1000-1200 bottles per hour. It is made of high-quality stainless steel, which makes it durable and easy to clean. The machine is also equipped with a touch screen control panel that makes it easy to operate. We are automatic beer bottling machine factory from China, we provide high quality automatic beer bottling machine for you.

Components

The machine consists of several components that work together to ensure that the beer bottling process is efficient. These components include a bottle washing machine, a filling machine, a capping machine, and a labeling machine. The bottle washing machine is designed to clean the bottles before filling them with beer. The filling machine is responsible for filling the bottles with beer, while the capping machine seals the bottles with caps. The labeling machine is designed to label the bottles with the necessary information, such as the brand name and alcohol content.

How to use

Using the 1000-1200BPH automatic beer bottling machine is relatively easy. First, you need to ensure that the machine is properly installed and connected to a power source. Next, you need to fill the machine with beer and set the necessary parameters on the touch screen control panel. Once the machine is set up, you can start the beer bottling process by placing the bottles on the conveyor belt. The machine will automatically wash, fill, cap, and label the bottles.

How to maintain

To ensure that the 1000-1200BPH automatic beer bottling machine remains in good working condition, it is essential to carry out regular maintenance. This includes cleaning the machine after use, lubricating the moving parts, and replacing any worn-out parts. It is also important to ensure that the machine is properly stored when not in use to prevent damage.

Effect of use

The 1000-1200BPH automatic beer bottling machine has several benefits. First, it streamlines the beer bottling process, making it faster and more efficient. This, in turn, increases productivity and reduces labor costs. The machine also ensures that the beer is packaged in a hygienic manner, which is essential for maintaining the beer's quality. Additionally, the machine reduces the risk of contamination, which can lead to spoilage and loss of revenue.

In conclusion, the 1000-1200BPH automatic beer bottling machine is an essential tool for any beer production company. It is designed to streamline the beer bottling process, making it faster, more efficient, and hygienic. By using this machine, beer production companies can increase productivity, reduce labor costs, and ensure that their beer is packaged in a high-quality manner.

Senmo machinery is one of the well-known beer filling equipment manufacturers in China, if you are going to purchase beer filling equipment, please contact us as soon as possible to get the best price.

FAQ

Q1: What is a 1000-1200BPH automatic beer bottling machine?

A 1000-1200BPH automatic beer bottling machine is a cutting-edge piece of equipment designed to automate the process of filling and capping beer bottles at a rate of 1000 to 1200 bottles per hour. This technology ensures accuracy, consistency, and efficiency in the bottling process.

Q2: How does the automatic bottling machine work?

Bottles are loaded onto a conveyor, and the automatic bottling machine takes care of the rest. The machine typically includes processes such as bottle rinsing, purging with carbon dioxide to minimize oxygen exposure, filling the bottles with beer, and capping. The synchronized operation ensures a seamless and controlled packaging process.

Q3: What are the benefits of using a 1000-1200BPH automatic bottling machine?

Automatic bottling machines offer a range of benefits, including increased production efficiency, precise filling levels, reduced oxygen exposure, improved product quality, and minimized labor requirements.

Q4: Is this machine suitable for small to medium-sized breweries?

Yes, this machine is particularly well-suited for small to medium-sized breweries. It provides an optimal balance between throughput and automation, making it an ideal solution for breweries looking to enhance their packaging processes without the complexity of large-scale automated systems.

Q5: Can the machine handle different bottle sizes and types?

Most 1000-1200BPH automatic bottling machines are adaptable and can accommodate various bottle sizes and types commonly used in the brewing industry. This flexibility allows breweries to package a diverse range of products.

Q6: How fast can the machine operate?

As the name suggests, the machine operates at a rate of 1000 to 1200 bottles per hour. This level of throughput significantly accelerates the bottling process compared to manual or semi-automated methods.

Q7: What maintenance is required for the automatic bottling machine?

Regular maintenance is essential to keep the machine in optimal working condition. This includes cleaning, sanitizing, inspecting and replacing parts as needed, and addressing any technical issues promptly to ensure uninterrupted operation.

Q8: Can the machine integrate with other brewery systems?

Yes, the 1000-1200BPH automatic bottling machine can integrate seamlessly with other brewery systems, such as conveyors, labeling machines, and quality control devices. This integration creates a synchronized and efficient packaging line.

Q9: What safety measures should be considered when using the machine?

Safety is a top priority when operating machinery. Ensure that your staff is properly trained in the operation of the machine and provided with the necessary protective gear. Regular inspections and adherence to manufacturer guidelines contribute to a safe working environment.

Q10: How can I choose the right automatic bottling machine for my brewery?

When selecting a 1000-1200BPH automatic bottling machine, consider factors such as your brewery's production capacity, bottle sizes, available space, desired automation level, and budget. Consulting with us and we can help you make an informed decision.