1000L 1200L beer whirlpool tank for microbrewery

In the world of microbreweries, precision and innovation are the keys to producing exceptional craft beer. Microbrewers are known for their dedication to the art and science of brewing, constantly seeking ways to elevate the quality of their brews. Enter the 1000L and 1200L beer whirlpool tanks, essential equipment that is revolutionizing the way microbreweries approach the brewing process.

The purpose of the 1000L 1200L beer whirlpool tank for microbrewery

The wort shall be quickly put into the rotary sedimentation pan to precipitate the hot coagulates produced in the boiling process for removal.It is necessary to remove the thermal coagulants (protein, bitter substances..etc.), because it will inhibit the fermentation of wort and shorten the shelf life.The whole process is controlled within 20-40 minutes

Whirlpool tank makes use of centrifugal force and gravity to make the thermal solidification and hops residue formed during boiling gradually gather in the center of the tank during sedimentation, forming steamed bread like sediment, so as to achieve solid-liquid separation.

The wort feed inlet is designed with an angle of 15 ° - 25 ° from the tangent direction, so as to avoid friction between wort and the tank wall when entering the tank, loss of kinetic energy, interference with wort rotation in the tank, formation of local turbulence, and impact on the sedimentation of particles.

There is a sloping bottom structure on the tank bottom structure, and the entire tank bottom inclines to the drain outlet with a slope of 2%; There is also a trough pan bottom structure. The trough bottom forms a slope of 2% from the center to the periphery, and a wort collecting tank with a slope is set in the circumference.

The hot solidified material jetting and flushing device can be either hydraulic spin type or mechanical spin type. The design requires that the hot solidified material be flushed out of the sedimentation tank in 6-8 minutes.

In consideration of the requirements of environmental protection, a thermoset tank shall be configured to collect the thermoset and pump it to the filter tank to be discharged together with the wheat lees before the filter tank is drained.

The process parameters require that the top space shall not be less than 15% of the full volume. The wort feeding speed is 3~5m/s and it rotates counterclockwise. The wort was clarified by swirling flow for 20 minutes. The wort feeding time is 12min. The cooling time of wort discharge is 50min.

The above is a brief description of the functions, characteristics and process parameters of the 1000L 1200L beer whirlpool tank for craft beer. In general, a set of qualified beer equipment should be designed, manufactured and installed according to the characteristics of craft beer, taking into full consideration the adaptation, cleanness, efficiency, oxygen avoidance, energy conservation, safety and other factors of the equipment, so as to meet the needs of craft beer production.

Below is some key parameters of the beer whirlpool tank:

SUS304 Inner tank thickness:3mm;SUS304 Outer tank thickness:2mm

100% TIG welding with pure argon gas shield

Surface process of the tank:Brushed surface

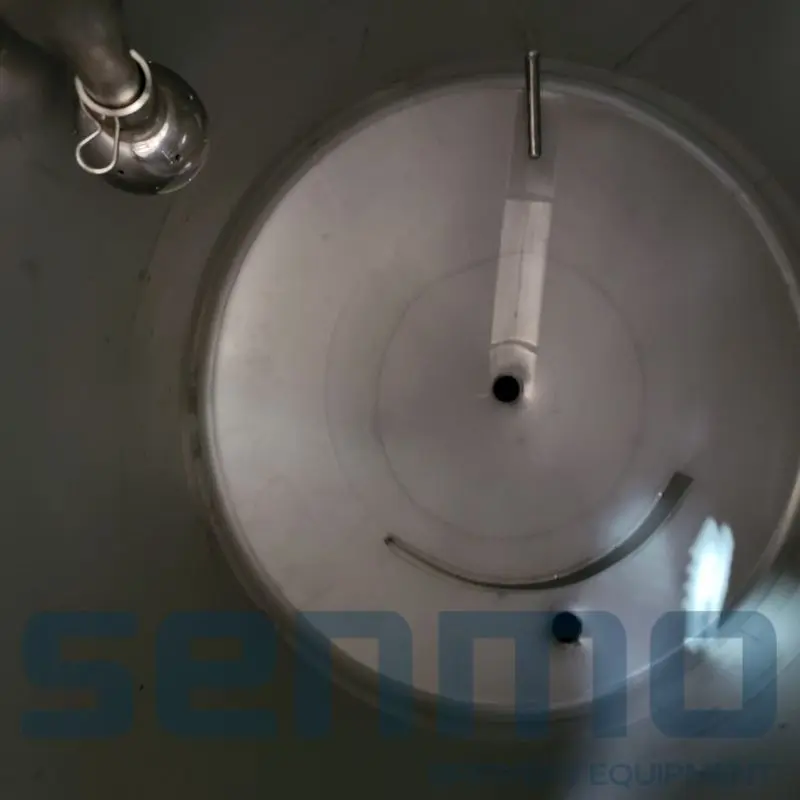

Interior of the tank do acid washing and passivation

Head type:Dished head,bottom cone

Insulation material and thickness:mineral wool insulation, thickness 100mm

All glass quick open manhole,with safety switch;brewery logo printed.

Sight glass/Level indicator

Drain port ,Wort outlet

With side tangent whirlpool inlet port

Four stainless steel legs, with screw assembly to adjust leg height;

CIP rotating balls with CIP pipe connection for washing cycle;

LED light

PT-100 temperature probe monitoring the product and the adjustment

Other matched pipes and joints

As a professional beer equipment manufacturer,SENMO always dadicate to give the most complete and functional brewing equipment to our clients with lower investment from them. If you have interest in the 1000L beer whirlpool tank and want to know details cost,please contact with us,we have sales engineers who can give you the formal quotation.

FAQ

1. What is a beer whirlpool tank, and why is it important for microbreweries?

A beer whirlpool tank is a vessel used in the brewing process to separate solids (such as hops and proteins) from the liquid wort after boiling. It is essential for enhancing the clarity, flavor, and aroma of the final beer.

2. What are the key benefits of using a 1000L or 1200L beer whirlpool tank in a microbrewery?

The primary benefits include efficient separation of solids, aroma and flavor enhancement, precise temperature control, time savings, and the capacity to handle larger batches, which is crucial for maintaining consistency in the brewing process.

3. How does a whirlpool tank enhance the flavor and aroma of beer?

Whirlpool tanks create a gentle swirling motion of the wort, concentrating essential oils and aroma compounds from hops. This process contributes to a richer and more vibrant beer flavor and aroma profile.

4. Can a microbrewery customize the whirlpooling technique with these tanks to create unique beer recipes?

Yes, microbreweries have the flexibility to customize their whirlpooling techniques, allowing them to experiment with new recipes and brewing styles. These tanks provide a platform for innovation and creativity.

5. What is the capacity of a 1000L and 1200L beer whirlpool tank?

A 1000L tank has a capacity of 1000 liters, and a 1200L tank has a capacity of 1200 liters. The choice between these two capacities depends on the specific production needs of the microbrewery.

6. How does temperature control work in these whirlpool tanks?

These tanks are equipped with advanced temperature control systems that allow microbreweries to precisely manage the wort temperature during the whirlpooling phase. This control is vital for achieving consistency in the brewing process.

7. What is the material of construction for these whirlpool tanks?

Whirlpool tanks are typically constructed from high-quality stainless steel (such as SUS304 or SUS316) to ensure durability and sanitary conditions, which are crucial for brewing.

8. Are these whirlpool tanks easy to clean and maintain?

Proper cleaning and maintenance are essential for the longevity of whirlpool tanks. Manufacturers often provide guidelines and recommendations for cleaning and maintenance, making it a manageable process for microbreweries.

9. How can a microbrewery acquire a 1000L or 1200L beer whirlpool tank for its brewing operation?

Microbreweries can acquire these tanks by contacting our customer service staff that specialize in brewery equipment. They will provide pricing information and guide the microbrewery through the purchasing process.

10. Are there any safety considerations when operating a beer whirlpool tank in a microbrewery?

Safety is a paramount concern. Microbreweries should ensure that their staff receives proper training in operating the equipment safely. Following safety protocols and complying with regulations is vital to creating a secure brewing environment.