In the heartland of brewing traditions, where precision and quality meet innovation, our 1000L Commercial Brewery Equipment stands as a testament to the art of brewing. Designed with the renowned German commitment to excellence in mind, this brewing setup reflects our dedication to providing top-tier brewing solutions for our valued clients in Germany.

1000L commercial brewery equipment germany

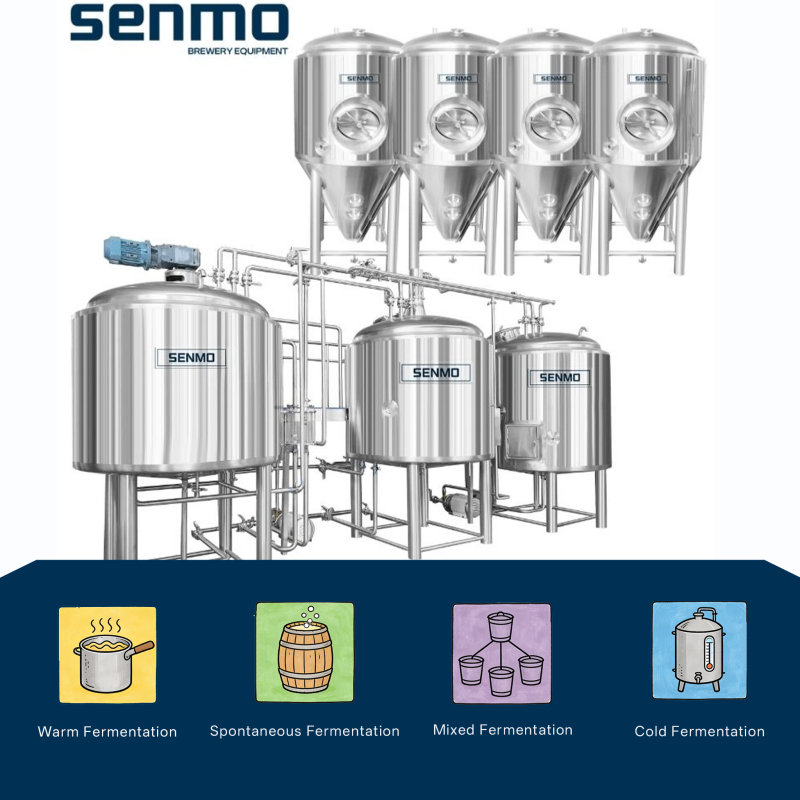

This is a whole set of 1000L commercial brewery equipment for Germany market.The entire brewery equipment include 3-vessel brewhouse and 4*1000L beer fermenters.All of the 1000L commercial brewery equipment and work will be in compliance with the following norms and standards to meet the Germany brewing equipment standard requirements.

Machinery Directive 2006/42/EC According to harmonized standard EN ISO 12100:2010

Low Voltage Directive 2014/35/EU

Health and Safety requirements of the Directive 2006/42/EC

-All material of the 1000L commercial brewery equipment in contact with product will be of Stainless Steel,304.Light glass made of glass.

-Pipe/Fitting standard will be designed according to your request

-All valves in contact with product will be of Hygienic Butter Valve Type

-All components and wire will be with CE marked

-Process connections will be designed according to your request.Sanitary screw couplings or Sanitary Tri-clamp

-Welds will be fully burned,shield gas will be used.With no pores,cracks.

The 1000L commercial brewhouse system inculde the following equipment:

-1000L steam heated mash kettle with grist hydator

-1000L wort filter tank with sieve plate

-1000L wort kettle and whirlpool tun

-Wort pump and hot water pump

-Stainless steel pipelines

-Valves and fittings

-Wort grant tank

-Plate heat exchanger

-Commercial electric steam boiler

-Hops fileter

-Control cabinet

The 1000L commercial brewery fermenter configuration:

Working volume:1000LTotal volume:1320LSize:φ1260×2510

Design temperature:Min:0℃ Max:100℃

Design pressure:2BarWorking pressure:1Bar

Inner tank thickness:2.5mmOuter tank thickness:2mmSurface process of the tank: Brushed surface

Head type:Dished headBottom type:Conical bottom,60°degree.

Insulation material and thickness:PU insulation,80mm

Cooling jackets around the cylinder and bottom cone.Cooling area: 2.2㎡

Dimple jacket design pressure:2BarDimple jacket working pressure:1Bar

CIP pipeline and CIP rotary spray ball

Side manhole

Hops dosing port on the top.Hoping entrance on the cylinder

Matched with Breath valve: Adjust the negative and positive pressure.

Matched with Sample valve

Matched with Pressure gauge and Mechanical Pressure regulating valve

Racking arm on the coneDrain outlet on the bottom

Four stainless steel legs, with screw assembly to adjust leg height, the base plate with two fixed hole;With brace between the legs

The 1000L commercial brewery equipment plates and accessories are made of international standard SUS304 stainless steel; Laser cutting and argon shielded welding, internal centralized pickling and passivation, accuracy ≤ 0.4 μ m; Polyurethane foam insulation; Pipe fittings support DIN, ISO, SMS and other customized standards; Dimple cooling jacket test pressure 0.4MPa; The working pressure of the tank is 0.15 MPa, and the test pressure is 0.4 MPa;

High precision temperature sensor, pressure sensor, liquid level sensor and other components, Siemens PLC control, program input, multi process formula storage and setting, simple operation;Accessories of auxiliary machines are selected from domestic and foreign first-line brands, which are CE/UL certified.

The following high-quality services will be obtained when purchasing SENMO beer equipment. We not only sell beer equipment, but also provide one-stop service, so that the equipment you buy can generate commercial value:

Sales consulting. SENMO provide fast, professional and detailed beer brewery equipment configuration list and the best brewery layout according to customer requirements.

Brewery technical design. According to the concept of customization, put forward design suggestions, integrate customer requirements, issue beer brewing process flow diagrams,micro brewery floor plans,machinery, electrical and other drawings, draw 3D drawing, and provide one-to-one tracking services.

Brewery equipment processing and manufacturing. Strictly implement the requirements of beer equipment design drawings, follow the IOS9001 quality management system, strictly control the quality of all links, and provide tanks test records of plates, welding, polishing, pressure, etc. for filing.

Brewery plant delivery and installation. The professional brewery project construction team conducts on-site installation, commissioning and training to ensure accurate delivery for use and continuous tracking maintenance.

If you want to renovate or upgrade your hotel's beer brewing equipment in Germany, the above suggestions are something to consider. We have transformed many hotels, bars, beer houses and other commercial beer equipment in Germany. Because of the diversity of equipment that can be provided, it meets the customization needs of different customers.

FAQ

Q1: What makes the 1000L commercial brewery equipment suitable for German breweries?

A1: The 1000L capacity is optimal for larger-scale production, catering to the demands of German breweries, beer gardens, and establishments. It aligns with the volume needed to meet the expectations of the discerning German beer culture.

Q2: How does the stainless steel craftsmanship contribute to the brewing process?

A2: Crafted from high-quality stainless steel, our brewery equipment ensures durability, corrosion resistance, and a sanitary brewing environment. This choice of material aligns with the German commitment to maintaining the purity and integrity of their renowned beer.

Q3: Can the brewing technology be customized to meet specific requirements?

A3: Yes, our brewing setup comes with a modular design, allowing brewers to adapt the configuration to meet specific production requirements. This flexibility ensures efficiency and versatility in the brewing process.

Q4: How does the brewery equipment ensure quality control for consistent beer production?

A4: Rigorous quality control features are integrated into our brewing system. This allows brewers to maintain consistency in each batch, ensuring that the beer produced adheres to the high standards associated with German brewing traditions.

Q5: What efficiency benefits does the 1000L brewery equipment offer?

A5: Efficiency is at the core of our brewing system. The streamlined design optimizes brewing processes, saving time and resources to enhance overall brewery efficiency.

Q6: Is the equipment suitable for both traditional and modern brewing environments?

A6: Yes, our brewery equipment is designed to cater to a range of brewing environments, from traditional German breweries in serene villages to modern craft breweries in bustling urban landscapes.

Q7: How does the precision craftsmanship contribute to the reliability of the brewing system?

A7: Meticulously crafted components embody the precision and attention to detail synonymous with German engineering. This contributes to a reliable and efficient brewing system, upholding the legacy of German beer culture.

Q8: Is the 1000L brewery equipment customizable to specific brewing processes or beer styles?

A8: Yes, our brewing system is designed with flexibility in mind. Brewers can customize the equipment to meet specific brewing processes or experiment with various beer styles, ensuring adaptability to the dynamic German brewing landscape.

897.webp)