1000L whisky distillery tower for brewery

Distillation is the process of converting distillate from liquid to loquid gas and then to liquid by using heat energy. Because the boiling point of each component in the distillate is different, the proportion of each component in the liquid before and after distillation is also different.Our 1000L whisky distillery tower for brewery is designed and produced as per that principle,and the distillery still pot also can be customized designed as per your brewery beer production capacity.

Since the boiling point of alcohol is lower than that of water, alcohol and aromatic substances in water are easier to volatilize than that of water. During distillation, the amount of alcohol and aromatic substances volatilized is far more than that of water, and the concentration in the liquid condensed after it is converted into steam will also be the initial distillate.

When the wort fermentation is just completed, the proportion of water in the liquor is about 86% - 94%, that of alcohol is about 6% - 14%, and that of other compounds is about 0.1%. After distillation, only about 5% - 35% of water, 65% - 95% of alcohol and 0-0.5% of other compounds remain.

However, the actual production is not so simple. Alcohol and other aromatic substances do not volatilize uniformly at a fixed temperature. Thousands of different chemicals will be produced during the fermentation process, many of which will bring bad taste and even be harmful to human health. Therefore, the composition of the distilled liquid must be strictly controlled.

Even if it is below 100 ℃, water and impurities will evaporate, and the liquor obtained is not pure and has high alcohol content. Therefore, one distillation is not enough. Generally speaking, at least two distillation should be carried out.

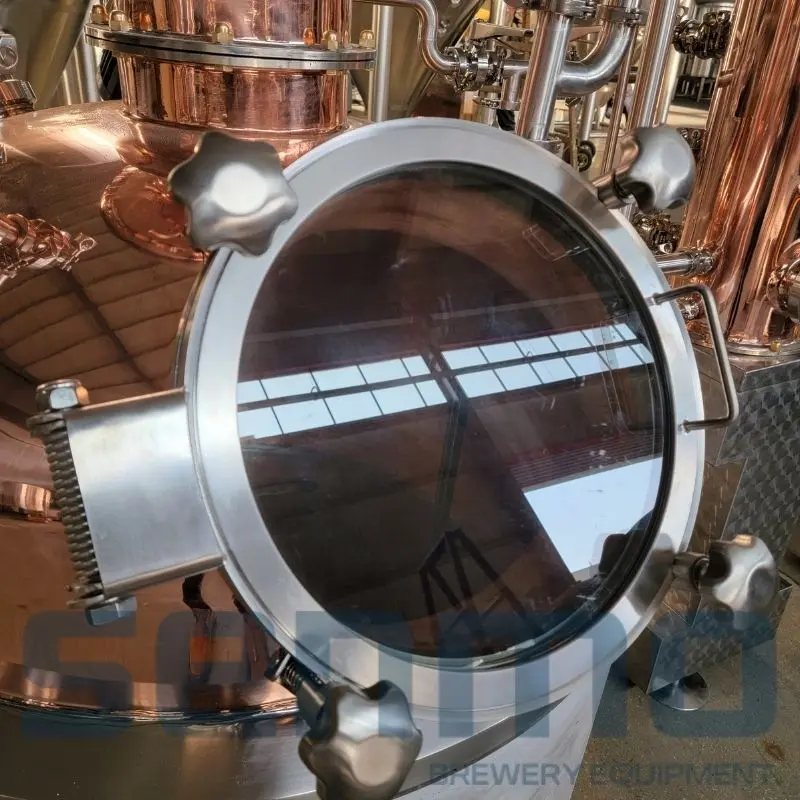

The pot still is mainly divided into 5 parts: pot, swan neck, Lynn arm, condenser, safe and auxiliary reflux device.

Pot is the main container used to store distillate and heat it, with different properties and sizes.

Swan neck is a neck that extends upward from the port body and combines with the pot body to form various shapes such as onions, pears, lanterns, balls, etc. The utility model is used to allow the steam to rise, condense and return to the tank along the copper wall, so as to enhance the role of steam and copper. The length of swan neck has a decisive influence on the style of new wine.

Lyne arm is a copper arm extending horizontally from the swan neck. Its angle, lifting, level or drooping also has a decisive influence on the style of new wine. If the lifting angle is large, the reflux rate will be large. The reflux rate refers to the quantity of liquor returns to the distiller and the re-distilled before entering the condenser.Why does the length of the swan neck and the angle of Lynn's arm have a decisive influence on the style? Because the higher the reflux rate, the more interaction between gaseous,liquid alcohol and copper, and the liquor much purer ; Otherwise, it will be thicker.

Condenser is a device used to condense steam. Traditionally, the copper tube with the same size of Lynn arm is gradually reduced to 3 inches (76 mm) in diameter,in round shape and immersed in the water tank to achieve the purpose of cooling. This device is called Worm tub.However, the condensation speed of worm tub is slow. Now most distilleries use shell and tube condenser with vertical copper cylinder and many small copper tubes inside. When in use, the condensed water is in the copper tube from bottom to top, and the alcohol vapor is condensed when it is cold and then slides down the copper tube from top to bottom. The bottom temperature of the condenser is kept at about 20 ℃, which is used to measure the alcohol content under standard environment.

The auxiliary reflux device is a device installed on the swan neck or Lynn arm to promote the reflux, so as to increase the efficiency of the swan neck and Lynn arm and increase the reflux rate.

If you want to add a whisky distill equipment in your brewery,you can ask us for the inquiry.Our company has various volumes still pots for sale,and all of the equipment can be customized design.You can tell us your general requirements on the equipment,we can make the quote for you.

FAQ

1. What is a whisky distillery tower, and how does it work in a brewery setting?

A whisky distillery tower, also known as a column still or distillation tower, is an essential component of the distillation process in a brewery. It's used to separate and purify alcohol from the fermented mash, allowing for the creation of high-quality spirits like whisky.

2. What is the capacity of the 1000L whisky distillery tower?

The 1000L whisky distillery tower is designed to handle a maximum capacity of 1000 liters of fermented mash for distillation.

3. Is the 1000L whisky distillery tower suitable only for whisky production?

While the primary focus is on whisky production, our distillery tower can be used for various distillation purposes, such as producing other spirits like vodka, gin, and rum.

4. What materials are used in the construction of the distillery tower?

Our distillery tower is constructed using high-quality materials such as stainless steel, ensuring durability, resistance to corrosion, and compliance with sanitary standards.

5. Does the 1000L distillery tower come with customizable options?

Yes, we offer customization options to tailor the distillery tower to your specific requirements. This can include design elements, materials, and additional features.

6. What additional equipment might be needed to complement the 1000L distillery tower?

Depending on your specific setup and production goals, you might need fermenters, mash tuns, condensers, and other auxiliary equipment to create a complete distillation system.

7. How is the installation process for the distillery tower handled?

Our experienced team can provide installation guidance and support to ensure the distillery tower is set up correctly and safely in your brewery.

8. Is there a warranty offered for the 1000L distillery tower?

Yes, we offer warranties for our distillery equipment. The warranty details can vary based on the equipment and purchase terms. Please contact us for specific warranty information.

9. Can I receive technical support or training for operating the distillery tower?

Absolutely. We offer technical support and training to ensure you're confident in operating the equipment effectively and achieving the best results.

10. How can I get more information and inquire about the 1000L whisky distillery tower for my brewery?

To learn more about the 1000L whisky distillery tower, pricing, customization options, or any other inquiries, please don't hesitate to contact our team using the provided contact information. We're here to assist you in enhancing your distillation capabilities.