2000L conical beer fermenter for sale

The 2000L conical beer fermenter is a pinnacle of modern brewing technology, designed to elevate the fermentation process in breweries to new heights. As one of the essential components in the brewing journey, this fermenter plays a critical role in transforming wort into exquisite beer, refining flavors, and achieving the desired characteristics that captivate beer enthusiasts worldwide.

Key Features and Advantages:

Large Capacity: With a generous capacity of 2000 liters, this conical fermenter is ideal for breweries seeking to produce substantial batches of beer while maintaining consistency and quality.

Conical Design: The conical shape of the fermenter allows for efficient yeast sedimentation during fermentation. As the yeast activity subsides, it settles at the bottom, making it easier to harvest and recycle for future brews.

Stainless Steel Construction: Crafted from premium-quality stainless steel, the fermenter ensures durability, corrosion resistance, and ease of cleaning, maintaining a hygienic environment for fermentation.

Temperature Control: Equipped with advanced temperature control systems, brewers can precisely manage the fermentation process, ensuring optimal conditions for yeast activity and desired flavor development.

Pressure Relief and Carbonation: The fermenter is equipped with pressure relief valves, allowing for controlled release of carbon dioxide during fermentation. This also facilitates natural carbonation, reducing the need for additional carbonation steps.

Sampling and Monitoring Ports: Convenient sampling and monitoring ports are strategically placed, enabling brewers to monitor the fermentation progress and take samples for analysis without disrupting the process.

CIP Cleaning System: The fermenter is designed with a CIP (Clean-In-Place) system, simplifying the cleaning process and maintaining sanitary conditions for successive brews.

Safety Features: The fermenter incorporates safety features such as pressure gauges and safety valves to ensure safe and reliable operations throughout the fermentation process.

Applications:

The 2000L conical beer fermenter is a versatile tool suitable for a wide range of breweries, including craft breweries, microbreweries, brewpubs, and commercial beer production facilities. Its large capacity and efficient design make it ideal for brewing various beer styles, from ales and lagers to stouts, IPAs, and specialty brews.

Conclusion:

The 2000L conical beer fermenter is a true asset to any brewery, empowering brewers to achieve consistent, high-quality beer production at scale. Its conical design, stainless steel construction, advanced temperature control, and other key features ensure precision and excellence in the fermentation process.

Investing in the 2000L conical beer fermenter marks a commitment to delivering exceptional beers that enthrall consumers, setting your brewery on a path of success and recognition within the craft beer community. Harness the power of modern brewing technology and take your fermentation process to the next level with the 2000L conical beer fermenter – where innovation meets craftsmanship, and every batch of beer becomes an artful creation. Cheers to the journey of crafting extraordinary beers with this remarkable fermenter at the heart of your brewery.

2000L 20HL 20BBL Commercial beer fementers general instruction

The whole fermentation tank is made by SUS304 stainless steel plate,which can meet the internation food sanitary standard.It is double layers with insulation in the middle,the thickness of the inner wall is 3mm,outer plate is 2mm,polyurethane insulation thickness is 80mm.The tank top is dished head,bottom is 60° cone.4 stainless steel legs with 4 braces between the legs.

Top many fermenter and side manhole fermenter

Commonly,there are 2 positions of the fermenter manhole,one is on the top of the tank,the other is on the side.It really depends on the clients' request on it.With top manhole,the insulation of the tank wall is better,with side manhole,it can make brewer get into it more easier.

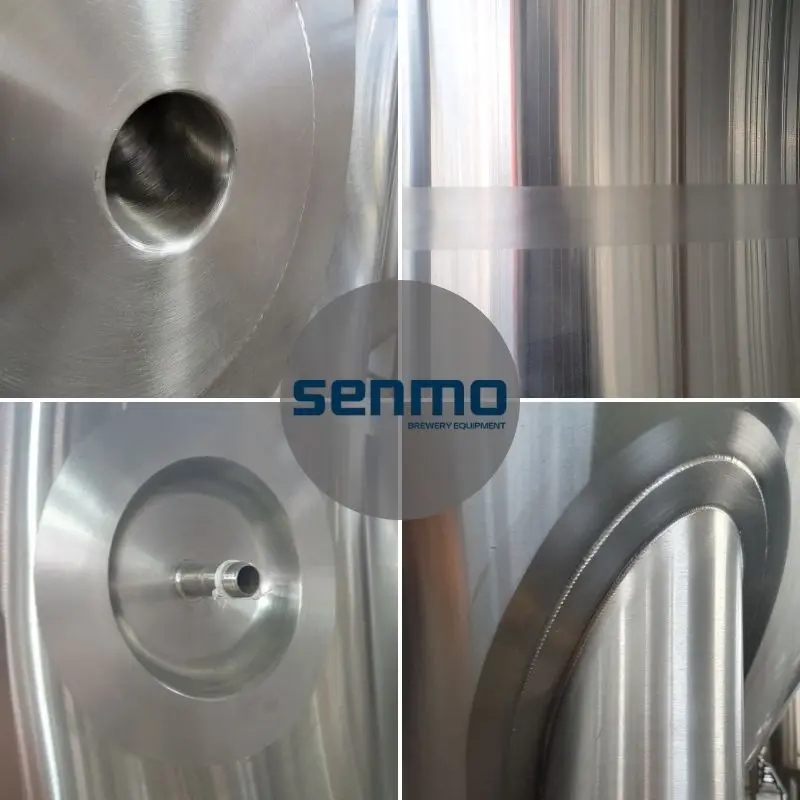

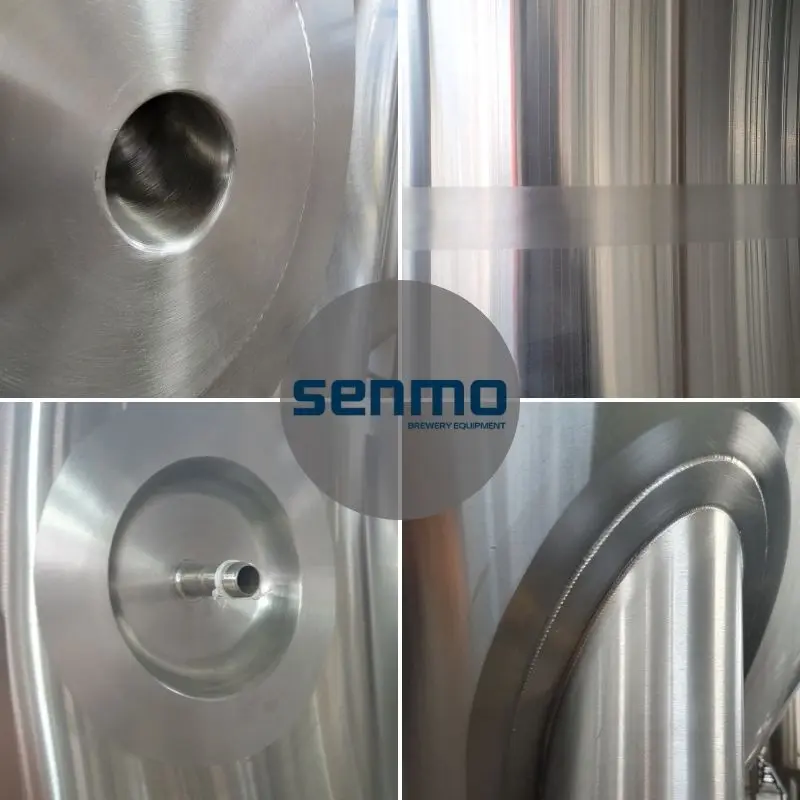

Tanks pipe ports on the fermentation tanks

We can see the manhole,the temperature sensor port,the glycol water pipe on the cone and 3 ports on the cone.The 3 ports are beer outlet let,CO2 carbon stone port and the beer sample valve port.The connection type of the pipe port can be designed as per clients' requirements,the commonly way is Tri clamp quick connection,there are Dairy coupler connection way and welding type can be optional.

SENMO focus more on the details of the tanks.All the tanks are TIG welded,after welding finishing,we do the pickling passivation on the welding seam place,or we the sanding belt polishing to make the outlook much cleaning.

The tanks are equipped with beer sample valve,the CO2 carbon stone,rotary beer racking arm,temperature senor when you use,also there are some other parts such as safety valve,pressure regulating valve,butterfly valves are needed.

There is solenoid valve,ball valve between the glycol water pipe and dimple cooling jacket.It can control the cooling water flow circulate loop to cool down the beer temperature.

If you have plan to expand you brewery plant production capacity,adding extra fermenters is one of the way.SENMO provide the professional and complete expansion solution for your brewery,please send us inquiry for more information.Cheers!

FAQ

Q1: What is the capacity of the 2000L conical beer fermenter?

A: The 2000L conical beer fermenter has a total capacity of 2000 liters, making it suitable for brewing substantial batches of beer.

Q2: Is the conical design of the fermenter essential for the fermentation process?

A: Yes, the conical design of the fermenter is crucial for efficient fermentation. It allows yeast to settle at the bottom, simplifying yeast harvesting and facilitating the removal of sediment, resulting in clearer and better-quality beer.

Q3: What is the material used in the construction of the 2000L conical beer fermenter?

A: The 2000L conical beer fermenter is constructed from high-quality stainless steel, which ensures durability, resistance to corrosion, and ease of cleaning.

Q4: How does the temperature control system work in the fermenter?

A: The temperature control system in the fermenter allows brewers to precisely manage the fermentation temperature. This is crucial for controlling yeast activity and achieving the desired flavor profile in the beer.

Q5: Can I ferment different types of beer in the 2000L conical beer fermenter?

A: Yes, the 2000L conical beer fermenter is versatile and can be used to ferment various types of beer, including ales, lagers, stouts, IPAs, and more.

Q6: Is the fermenter equipped with safety features?

A: Yes, the 2000L conical beer fermenter is equipped with safety features, such as pressure gauges and safety valves, to ensure safe and reliable operations during fermentation.

Q7: How often should the fermenter be cleaned?

A: The frequency of cleaning the fermenter depends on the brewing schedule and the type of beer being brewed. However, regular cleaning after each batch is essential to maintain a sanitary environment for the next brew.

Q8: Can I monitor the fermentation process in the 2000L conical beer fermenter?

A: Yes, the fermenter is equipped with sampling and monitoring ports, allowing brewers to monitor the fermentation progress and take samples for analysis without disturbing the process.

Q9: Can the 2000L conical beer fermenter be used in commercial beer production?

A: Absolutely! The 2000L conical beer fermenter is suitable for commercial beer production, making it a valuable asset for craft breweries, brewpubs, and larger-scale beer production facilities.

Q10: Is technical support available for the 2000L conical beer fermenter?

A: Yes, reputable manufacturers provide technical support and assistance, including installation guidance and operational training, to ensure brewers can use the fermenter effectively.

For more detailed information, technical specifications, and to explore the benefits of the 2000L conical beer fermenter for your brewery, feel free to contact our sales team. We are committed to helping you achieve exceptional fermentation results and craft extraordinary beers that leave a lasting impression on beer enthusiasts worldwide. Cheers to the art of brewing with the 2000L conical beer fermenter!