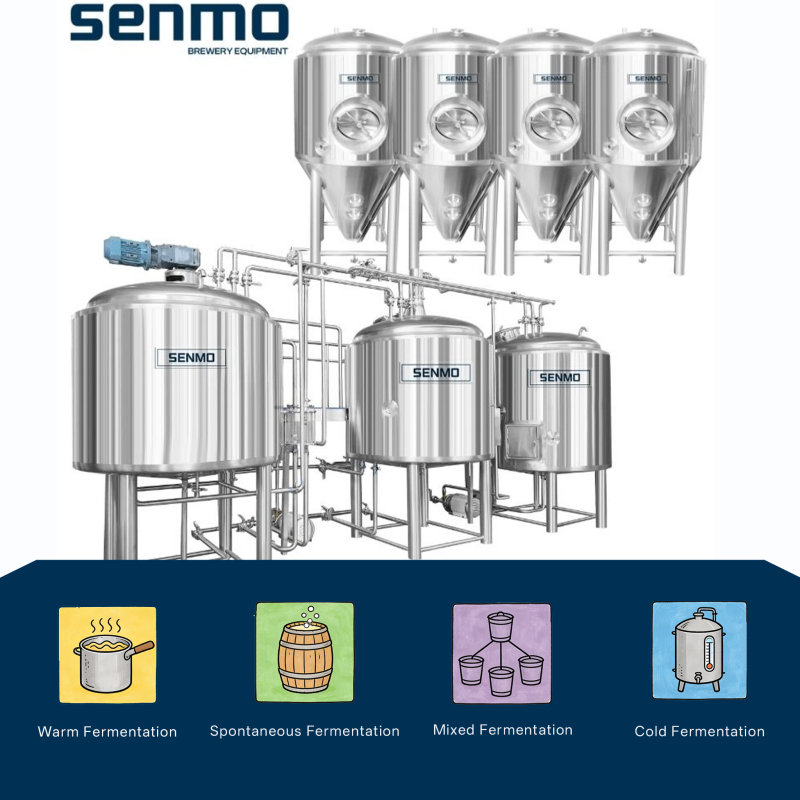

Stainless steel 500L beer fermentation system for microbrewery

As a manufacturer, we are proud to offer our Stainless Steel 500L Beer Fermentation System designed specifically for microbreweries. This state-of-the-art fermentation system is a crucial component of the brewing process, allowing microbreweries to produce high-quality beer with precision and efficiency. Here's an in-depth look at the features and benefits of our fermentation system:

1. Premium Stainless Steel Construction: Our fermentation tanks and all components are meticulously crafted from high-quality stainless steel. This material ensures durability, corrosion resistance, and ease of cleaning, meeting the strictest hygiene standards required in the brewing industry.

2. Optimal Capacity: The 500L capacity is perfect for microbreweries, enabling them to produce a substantial quantity of beer with flexibility. This size is ideal for experimental batches and small-scale production while maintaining consistency and quality.

3. Glycol Cooling System: Our fermentation system is equipped with a highly efficient glycol cooling system. The cooling jackets in the fermentation tanks ensure precise temperature control during the fermentation process, allowing brewers to achieve desired flavor profiles and consistent results.

4. Temperature Control and Monitoring: We have integrated advanced temperature control and monitoring features into the system. The brewmaster can easily set and monitor fermentation temperatures, ensuring that yeast activity and flavor development are optimized for each beer style.

5. Racking Arm and Sampling Port: To facilitate the separation of clear beer from sediment during transfer, each fermentation tank is equipped with a racking arm. Additionally, a sampling port is provided for easy monitoring of fermentation progress and quality checks.

6. Carbonation Options: Depending on the beer style and desired carbonation level, our fermentation tanks offer carbonation stone or ports for the introduction of carbon dioxide, allowing for precise and controlled carbonation.

7. CIP (Clean-in-Place) System: We understand the importance of proper cleaning and sanitation in the brewing process. Our fermentation system includes an efficient CIP system, making cleaning and maintenance a breeze, thus ensuring the integrity and hygiene of the entire brewing process.

8. Customization and Automation: We offer customization options to meet the specific needs of our customers. Depending on the brewery's requirements, our fermentation system can be manually operated or fully automated for ease of use and increased efficiency.

9. Safety and Reliability: Safety is of paramount importance to us. The fermentation system incorporates safety features, including pressure gauges, pressure relief valves, and safety interlocks, to ensure safe operation at all times.

10. Expert Technical Support: Our dedicated technical support team provides comprehensive assistance, from installation and setup to ongoing maintenance. We are committed to ensuring our customers' success and satisfaction with our fermentation system.

Our Stainless Steel 500L Beer Fermentation System is designed to empower microbreweries with the capability to produce exceptional beer with consistency and precision. We take pride in providing reliable, high-quality equipment that contributes to the success and growth of our customers' breweries. Should you have any inquiries or wish to explore our fermentation system further, please do not hesitate to contact our team.

There are stainless steel 500L fermentation system made by SENMO Machinery.The tank plates and accessories of the 500L fermentation system for microbrewery are made of international standard SUS304 stainless steel,however,if you want SUS316 stainless steel plates for the tanks,we can do the customized production for you.The beer tanks surface can be brushed polishing,mirror polishing or red copper,interior of the tanks also can be mirror polished if you want.

The tank plates and accessories are made of international standard SUS304 stainless steel;

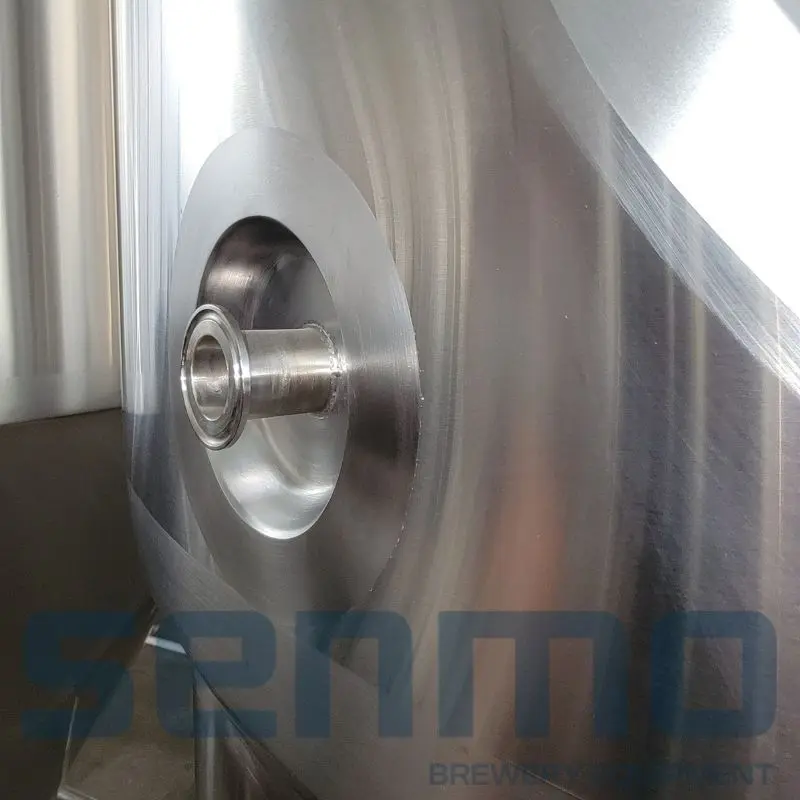

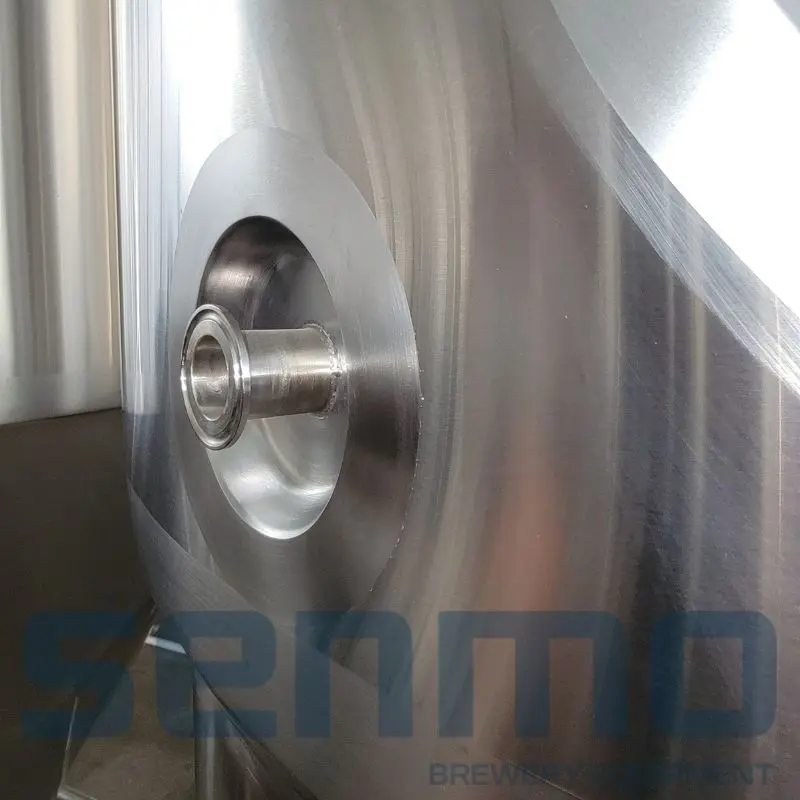

Laser cutting and argon shielded welding, internal centralized pickling and passivation, accuracy ≤ 0.4 μ m;

Polyurethane foam insulation;

Pipe fittings support DIN, ISO, SMS and other customized standards;

Refrigerant jacket test pressure 0.4MPa; The working pressure of the tank is 0.15 MPa, and the test pressure is 0.4 MPa;

Side manhole, lower 60 ° cone bottom;

High precision temperature sensor, automatic temperature control, real-time feedback of temperature curve, supporting remote operation;

It is equipped with safety valve, pressure regulating valve, sampling valve, liquor outlet valve, blow down valve, dry hops inlet, inflation valve, CIP cleaning ball, etc

We use Pickling and passivation production technology to the interior of the stainless steel 500L beer fermentation system for microbrewery

Pickling and passivation treatment is usually carried out in engineering to make the corrosion resistance potential of stainless steel greater. In the process of forming, assembling, welding seam inspection (such as flaw detection, pressure test) and construction marking of stainless steel equipment and components, surface oil, rust, non-metallic dirt, low melting point metal pollutants, paint, welding slag and splash are brought, which affect the surface quality of stainless steel equipment and components and damage the oxide film on their surfaces, It reduces the overall corrosion resistance and local corrosion resistance of steel (including pitting corrosion and crevice corrosion), and even leads to stress corrosion cracking.

The following fittings are matched with the fermenters:

-Mechanical pressure regulating valve

-Beer sample valve

-Breath valve

-Thermometer

-Hops dosing port

-Temperature sensor

-Beer rotary pipe

-Drain outlet

-CIP ball and CIP arm

-CO2 carbon stone

The connection of the fittings can be tri-clamp,diary couplers and other connection way you want.Meanwhile,if you need other fitings or port on the fermenters,you can tell us and we do the special design for you.

The stainless steel 500L fermentation system pipe fittings support DIN, ISO, SMS and other customized standards.The tanks top is stainless steel dished head, fermenters are lower 60 ° cone bottom,bright beer tanks are with dished bottom; The tanks manway can be on top or side of the fermenters. The cooling pipe connection can also be customized produce,you can choose tri-clamp connection,thread connection,diary coupler connection or other way you want.

If you want to learn more about the features of the stainless steel 500L fermentation system,please send us inquiry,our sales engineer can send you a detailed proposal.Below is the services which we can provide for you:

Sales consulting. SENMO provide fast, professional and detailed beer brewery equipment configuration list according to customer requirements.

Brewery technical design. According to the concept of customization, put forward design suggestions, integrate customer requirements, issue beer brewing process flow diagrams,micro brewery floor plans,machinery, electrical and other drawings, draw 3D drawing, and provide one-to-one tracking services.

Brewery equipment processing and manufacturing. Strictly implement the requirements of beer equipment design drawings, follow the IOS9001 quality management system, strictly control the quality of all links, and provide tanks test records of plates, welding, polishing, pressure, etc. for filing.

Brewery plant delivery and installation. The professional brewery project construction team conducts on-site installation, commissioning and training to ensure accurate delivery for use and continuous tracking maintenance.

FAQ

Q1: What is the capacity of the Stainless Steel 500L Beer Fermentation System?

A: The capacity of our fermentation system is 500 liters, making it ideal for microbreweries looking to produce smaller batches of high-quality beer.

Q2: What material is the fermentation system made of?

A: The entire fermentation system, including the fermentation tanks and all components, is constructed from premium-quality stainless steel. This material ensures durability, hygiene, and corrosion resistance.

Q3: Can the fermentation system accommodate different beer styles?

A: Yes, our fermentation system is designed to accommodate a wide range of beer styles. The precise temperature control and carbonation options allow brewers to produce diverse and consistent beer profiles.

Q4: Does the system come with a cooling feature?

A: Absolutely, our fermentation system is equipped with an efficient glycol cooling system. The cooling jackets in the fermentation tanks ensure precise temperature control during fermentation, providing optimal conditions for yeast activity and flavor development.

Q5: Is the system easy to clean and maintain?

A: Yes, we understand the importance of cleanliness and sanitation in the brewing process. Our fermentation system includes a CIP (Clean-in-Place) system, making cleaning and maintenance convenient and ensuring the integrity of the brewing process.

Q6: Can the fermentation system be customized to our brewery's needs?

A: Certainly, we offer customization options to tailor the fermentation system to meet the specific requirements of your microbrewery. Our technical team will work closely with you to design a solution that suits your brewing process.

Q7: Is the system manually operated or automated?

A: Depending on your preference and brewery setup, our fermentation system can be either manually operated or fully automated. We can provide automation options for increased efficiency and ease of use.

Q8: What safety features does the fermentation system include?

A: Safety is a top priority for us. Our fermentation system incorporates various safety features, including pressure gauges, pressure relief valves, and safety interlocks, ensuring safe and reliable operation.

Q9: Does your company offer technical support and assistance?

A: Absolutely, our dedicated technical support team provides comprehensive assistance, from installation and setup to ongoing maintenance. We are committed to ensuring your success and satisfaction with our fermentation system.

Q10: How can we get more information or request a quote for the fermentation system?

A: For more information or to request a quote for our Stainless Steel 500L Beer Fermentation System, please contact our sales team through our website or directly by phone or email. We will be delighted to assist you and provide all the necessary details to help you make an informed decision.