4000L commercial beer brewery equipment

40HL (hectoliters) or 4000L (liters) commercial beer brewery equipment refers to a large-scale brewing system designed for commercial breweries and production facilities. This equipment is capable of producing 40 hectoliters or 4000 liters of beer per batch. It is a significant step up from smaller microbrewery setups and is suitable for breweries looking to produce beer on a larger scale to meet commercial demands.

Key Components of 40HL/4000L Commercial Beer Brewery Equipment:

Mash/Lauter Tun: This vessel is used for mashing the malted grains with hot water to convert starches into fermentable sugars and lautering to separate the liquid wort from the solid grain husks.

Brew Kettle: The brew kettle is where the wort is boiled, and hops are added for bitterness, flavor, and aroma.

Whirlpool Vessel: After boiling, the wort is transferred to the whirlpool vessel, where it is gently stirred to create a whirlpool effect, separating trub and hop residues from the wort.

Fermentation Tanks: These large tanks are used for fermenting the wort with yeast to convert sugars into alcohol and carbon dioxide, turning the wort into beer.

Cooling System: A robust cooling system is employed to rapidly cool down the wort after boiling, allowing for the yeast to be added and fermentation to begin.

CIP (Clean-In-Place) System: The CIP system is used for automated cleaning and sterilization of the brewing equipment, maintaining a hygienic environment for brewing successive batches.

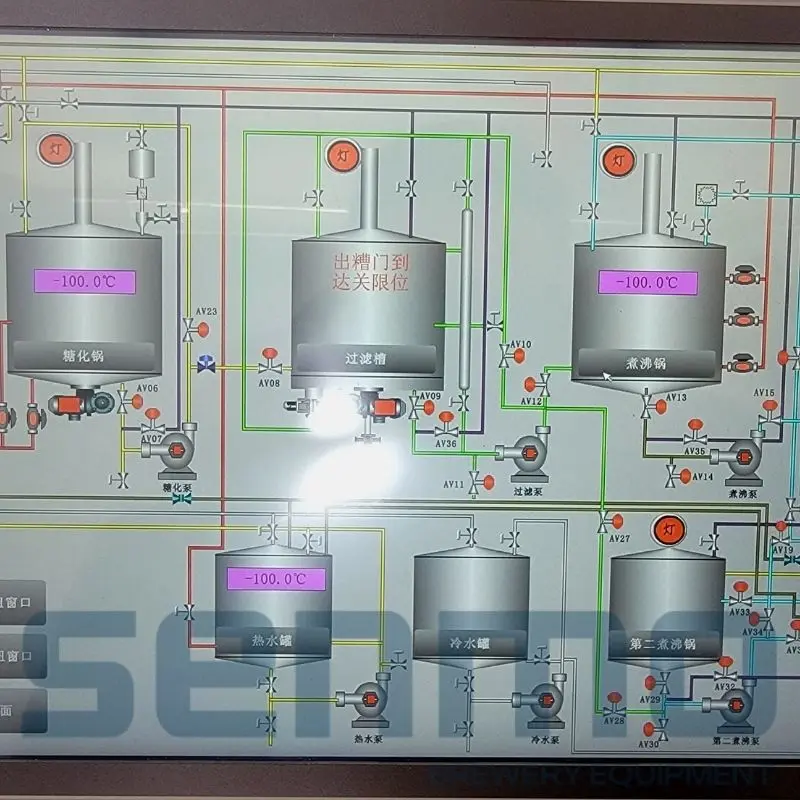

Control Panel: An advanced control panel enables brewers to manage various brewing parameters, such as temperature, time, and pumping, ensuring precise and consistent brewing.

Advantages of 40HL/4000L Commercial Beer Brewery Equipment:

High Production Capacity: The 40HL/4000L capacity allows breweries to produce significant volumes of beer to meet commercial demands.

Consistency and Efficiency: The large-scale equipment provides better process control, resulting in consistent and efficient brewing operations.

Scalability: The brewery equipment can be designed to be scalable, allowing for future expansions and increased production capacity.

Diverse Beer Styles: Breweries can use this equipment to produce a wide variety of beer styles, catering to different customer preferences.

Professional and Commercial Grade: Designed for commercial operations, the equipment is built with high-quality materials and craftsmanship, ensuring durability and longevity.

Applications:

The 40HL/4000L commercial beer brewery equipment is ideal for medium to large-sized commercial breweries, craft breweries, and production facilities. It is suitable for breweries seeking to scale up their operations and supply their beers to a broader market.

In conclusion, the 40HL/4000L commercial beer brewery equipment is a robust and sophisticated brewing system tailored to meet the demands of commercial production. Its capacity, efficiency, and versatility make it a valuable asset for breweries looking to take their brewing journey to the next level and reach a wider audience of beer enthusiasts.

The whole 4000L commercial beer brewery equipment for sale include the following items:

4000L mash tun with grist hydrator

4000L lauter tun with rake knife system

4000L wort kettle with inner calandria+hops adding device

4000L whirlpool tun with tangent whirlpool inlet

Wort pumps

Pleat heat exchanger

Pipes and valves

Sight glass

Control cabinet

789649.webp)

The tank plates and accessories are made of international standard SUS304 stainless steel; Laser cutting and argon shielded welding, internal centralized pickling and passivation, accuracy ≤ 0.4 μ m; Polyurethane foam insulation; Pipe fittings support DIN, ISO, SMS and other customized standards; Refrigerant jacket test pressure 0.4MPa; The working pressure of the tank is 0.15 MPa, and the test pressure is 0.4 MPa; Top stainless steel butterfly head, lower 60 ° cone bottom; High precision temperature sensor, automatic temperature control, real-time feedback of temperature curve, supporting remote operation; It is equipped with safety valve, pressure regulating valve, sampling valve, liquor outlet valve, blow down valve, dry inlet, inflation valve, CIP cleaning ball, etc.

Material:Sanitary food grade 304. The thickness of the plate is 3mm inside and 2mm outside.

Thermal insulation: rock wool thermal insulation,thickness 100mm. Due to the heating function of the equipment, polyurethane insulation will shrink and affect the insulation effect. The minimum thickness of the insulation layer is 80mm

Mixing: Large diameter low-speed mixing blades, suspension reducer and variable frequency control of the mixing speed should be used for mixing to avoid turbulence on the liquid surface during mixing and reduce oxygen absorption of the mash (upper mixing and lower mixing should be reasonably selected according to equipment requirements)

Heating area and method: The heating jacket shall be designed so that the heating steam enters the jacket evenly, and at the same time, it shall prevent the condensate from being discharged unobstructedly, forming a "water hammer" to damage the jacket.

Temperature control: It is better that the equipment is equipped with a directly readable thermometer. And choose different automatic temperature control devices according to their own economic strength (pneumatic angle seat valve temperature control, solenoid valve, etc.)

The structure of the equipment better to have liquid level. The empty capacity is more than 20%. Select a reasonable taper according to the size of the equipment.

Cleaning: the inside of the tank body is smooth and clean without dead corners, especially the welding quality of the welding joint treatment, which is smooth and clean, and the selection of cleaning balls is reasonable

The steam jacket will produce a large amount of condensate, which can be completely recycled. It can be used as softened water of boiler (for equipment with large capacity, it is recommended to add pipeline steam condensate recovery system to save energy consumption of boiler)

The material pipeline design is reasonable.

The feeding port of the equipment is located at the bottom or side of the tank, and the feeding speed should be less than 1.2m/s; The wort reflux port is located at the bottom or upper part of the tank, so the wort should not absorb oxygen and impact the lees layer during reflux; The wort collecting port is conical design, ≥ 1.2 pieces/m2, evenly distributed; The diameter and number of the drainage openings affect the drainage speed, and the design is to drain the wheat grains in the trough within 12 minutes; Filter function shall be available after the drain opening is closed. The wort collecting pipe is designed according to the principle of fluid mechanics, so that the wort can flow out in the same state in each collecting pipe; Screen plate: it is a machine milling screen plate. The screen plate hole is of ladder design, with a hole width of 0.7mm. After installation, the gap between the screen plates and between the screen plate and the tank is ≤ 0.7mm.

The cultivator blade is designed as a straight or cross shaped cultivator arm, which shall have rotation and lifting functions, and can be controlled continuously or in sections.

Nozzle type or central distribution cup type can be used for washing the grains, requiring large flow without impacting the grains layer.

The main shaft seal adopts high position seal, and the sealing surface is above the liquid level without leakage.

The liquid level control adopts the design of balance column (tank) or differential pressure to avoid the formation of slagging.

The total operation time shall be controlled within 180 min. The thickness of the lees layer is 220mm-400mm, meeting the needs of many varieties of fine brewing. Residual sugar from washing lees ≤ 2.5 ° P. Wort turbidity ≤ 20EBC.

In addition. There are generally two forms of filtration: suction filtration and natural filtration. If the high level difference cannot be formed, the natural filtration cannot be carried out. Generally, we will use the wort balance tank.

The intelligent central control can realize semi-automatic and automatic control. CNC display control, centralized display, automatic control of fermentation and refrigeration, manual and automatic switching, simple operation; Siemens PLC control system, touch screen display, various process parameters can be programmed and set according to customer requirements; Support remote mobile phone control, with strong scalability and convenient visual operation; Industrial personal computer automatic control, antimagnetic, dust-proof, impact proof, more reliable and stable; Expandability, compatibility, continuity, and communication are stronger and more convenient.

If you have plan to open a microbrewery with 4000L brewhouse system,we can help you do the beer brewing technical design,equipment design,place design and brewing teaching,a turnkey brewery system.Please send us your inquiry,we have sales engineer who can send you a professional proposal.Cheers!

FAQ

Q1: What is the capacity of the 40HL/4000L commercial beer brewery equipment?

A: The 40HL/4000L commercial beer brewery equipment has a production capacity of 40 hectoliters or 4000 liters per batch, making it suitable for medium to large-scale commercial brewing operations.

Q2: What are the key components included in the 40HL/4000L commercial beer brewery equipment?

A: The key components of the 40HL/4000L commercial beer brewery equipment typically include a Mash/Lauter Tun, Brew Kettle, Whirlpool Vessel, Fermentation Tanks, Cooling System, CIP System, and a Control Panel for precise management of the brewing process.

Q3: Is the brewery equipment suitable for producing various beer styles?

A: Yes, the 40HL/4000L commercial beer brewery equipment is versatile and can produce a wide range of beer styles, from ales and lagers to stouts, IPAs, and specialty brews.

Q4: Can the brewery equipment be customized to meet specific brewery needs?

A: Reputable manufacturers often offer customization options for the 40HL/4000L commercial beer brewery equipment, allowing breweries to tailor the setup to their specific requirements and preferences.

Q5: How efficient is the brewing process with the 40HL/4000L commercial beer brewery equipment?

A: The 40HL/4000L commercial beer brewery equipment is designed for efficiency and process control, resulting in consistent brewing operations and higher production throughput.

Q6: Is the brewery equipment easy to clean and maintain?

A: Yes, the 40HL/4000L commercial beer brewery equipment is designed with ease of cleaning in mind. The CIP (Clean-In-Place) system simplifies the cleaning and sterilization process, maintaining a sanitary brewing environment.

Q7: Can the brewery equipment be expanded for future growth?

A: Yes, the brewery equipment can be designed to be scalable, allowing breweries to expand their production capacity as their business grows.

Q8: Is technical support provided with the purchase of the brewery equipment?

A: Reputable manufacturers typically provide technical support, including installation assistance and operational training, to ensure brewers can efficiently use the equipment.

Q9: What types of brewing control are available with the equipment's control panel?

A: The control panel of the 40HL/4000L commercial beer brewery equipment allows brewers to manage various brewing parameters, including temperature, time, and pumping, enabling precise control over the brewing process.

Q10: Is the brewery equipment suitable for medium-sized craft breweries or larger production facilities?

A: Yes, the 40HL/4000L commercial beer brewery equipment is well-suited for medium-sized craft breweries and larger production facilities seeking to produce substantial volumes of beer for commercial distribution.

For more detailed information, technical specifications, and to explore the benefits of the 40HL/4000L commercial beer brewery equipment for your brewery, feel free to contact our sales team. We are dedicated to providing the tools to enhance your brewing journey and cater to the demands of the ever-growing craft beer market. Cheers to crafting exceptional brews with the 40HL/4000L commercial beer brewery equipment!

256.webp)

378.webp)