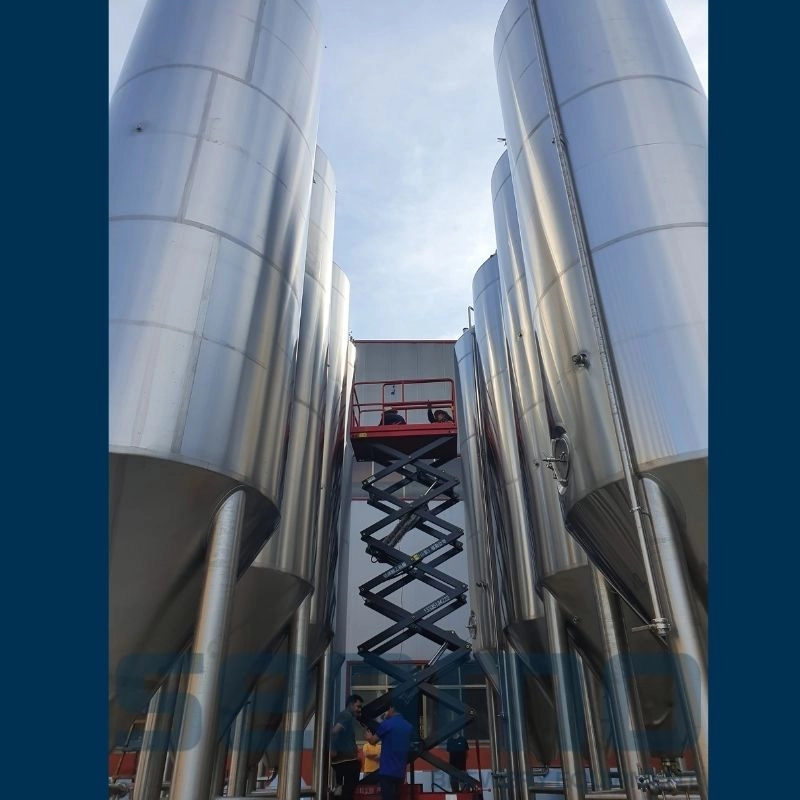

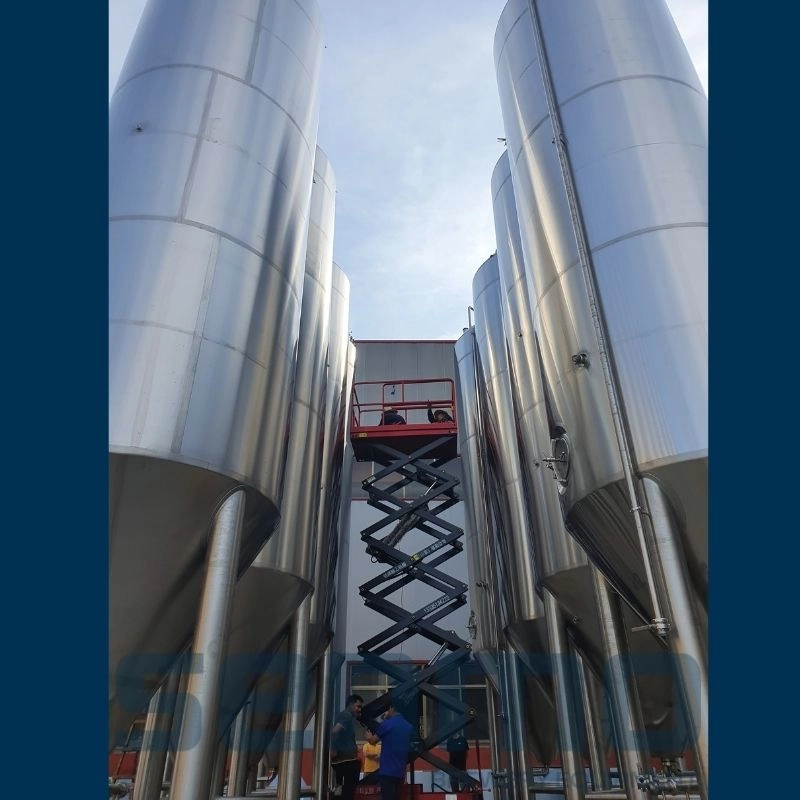

Commercial brewery plant 20000L beer fermenter for sale

Are you in the business of brewing, seeking to expand your production capacity, and maintain the highest standards of quality? Look no further! Our 20,000L beer fermenter is the solution you've been searching for. Here we will explore the numerous advantages and benefits of our exceptional product for commercial brewery plants.

Unleashing the Power of 20,000 Liters

Our 20,000L beer fermenter is more than just a vessel; it's a gateway to unlocking the true potential of your brewery. Here are some compelling reasons why our product can revolutionize your brewing operation:

1. Scalability and Increased Production Capacity

The 20,000L fermenter is a juggernaut in terms of capacity, allowing you to significantly boost production without the need for extensive expansions. Whether you're looking to meet growing demand or tap into new markets, our fermenter offers the scalability you need to keep your brewery at the forefront of the industry.

In the world of commercial brewing, staying ahead of the competition requires a keen eye on scalability and production capacity. Our 20,000L beer fermenter is your gateway to achieving these objectives and more.

Meeting Growing Demand

As your brewery gains popularity and a loyal customer base, the demand for your beer is likely to increase. While this is undoubtedly a positive sign for your business, it can also present challenges in terms of keeping up with production. Expanding your existing infrastructure can be costly and time-consuming, not to mention the logistical complexities involved.

Our 20,000L fermenter serves as a solution to this dilemma. With its colossal capacity, it offers a substantial production boost without the need for extensive expansions or investments in multiple smaller fermenters. This means that you can efficiently meet the ever-growing demand for your beer, all within the confines of your existing brewery setup.

Tapping into New Markets

When considering the expansion of your brewery, you may also be eyeing new markets and regions. These markets may have unique demands and preferences that require a flexible and adaptable brewing process. Our 20,000L fermenter provides the agility needed to venture into new territories with ease.

By utilizing a single large fermenter, you have the advantage of diversifying your beer offerings without the constraints of smaller batches. This not only saves you time and resources but also allows you to respond swiftly to market trends and consumer preferences. Whether it's expanding your product range, producing special limited-edition brews, or catering to niche markets, the scalability of our fermenter ensures you're well-prepared to take on new challenges.

Maintaining a Competitive Edge

In the fiercely competitive brewing industry, staying at the forefront of the market is essential. The ability to scale your production in line with market demand and expanding your reach into new regions can make all the difference. Our 20,000L beer fermenter empowers you to do just that.

With its unmatched capacity and adaptability, this fermenter ensures you're always ready to meet the needs of your customers and explore new opportunities. By investing in our product, you're not only enhancing your brewery's production capacity but also securing a competitive edge in a dynamic and ever-evolving industry.

The 20,000L beer fermenter is your brewing juggernaut. It's a game-changer for breweries seeking to meet growing demand, tap into new markets, and maintain their position as leaders in the industry. Whether it's boosting production capacity or staying agile in the face of market changes, our fermenter provides the scalability your brewery needs to succeed. Don't just meet demand; exceed it with our 20,000L beer fermenter.

2. Uncompromised Quality and Consistency

Consistency is the hallmark of a great brewery. Our 20,000L fermenter ensures that your beer maintains its quality batch after batch. Larger batches mean less room for variations, guaranteeing that your customers receive the same exceptional product every time.

In the world of brewing, consistency is not just a virtue but a hallmark of a great brewery. It's the assurance that each bottle or pint of your beer will deliver the same exceptional taste, aroma, and experience that your customers have come to expect. Our 20,000L beer fermenter is designed to be your partner in achieving and maintaining this unwavering quality and consistency.

Bigger Batches, Fewer Variations

One of the key ways our 20,000L fermenter ensures the consistent quality of your beer is by producing larger batches. Larger batches leave less room for variations between different brews. Here's how it works:

Homogeneity: When you brew in smaller fermenters, the composition of your beer can vary from batch to batch due to minor fluctuations in temperature, pressure, or ingredient distribution. However, with a 20,000L fermenter, the increased volume promotes better homogeneity, ensuring that the entire batch ferments at uniform conditions. This homogeneity is a critical factor in maintaining consistent quality.

Stability: Smaller batches are more susceptible to temperature fluctuations, which can affect the fermentation process and, consequently, the taste of your beer. In contrast, our large fermenter offers better thermal stability. This means the fermentation process remains more constant, minimizing any temperature-related variations.

Smoother Workflow: Managing multiple smaller fermenters can be challenging and may lead to inconsistencies in the brewing process. Our 20,000L fermenter streamlines your workflow. You have a single, well-controlled fermentation process, reducing the potential for human error and ensuring that each batch is brewed to perfection.

Consistency Across the Board

Consistency is not only about the flavor but extends to all aspects of your product. It includes the aroma, color, and mouthfeel of your beer. With our 20,000L fermenter, you can maintain these attributes consistently across all your batches. This level of reliability in your product is what sets you apart in a competitive market.

Customer Satisfaction

Consistency is synonymous with customer satisfaction. When your customers know they can rely on your brand to deliver the same excellent beer every time, they become loyal patrons. This loyalty translates into repeat business, word-of-mouth recommendations, and the growth of your customer base.

Quality Assurance

Consistency isn't just about taste but also about quality. By ensuring that every batch meets the same high standards, our 20,000L fermenter safeguards the integrity of your brand. You can proudly stand by the quality of your beer, building a reputation as a brewery that never compromises.

Our 20,000L beer fermenter is your assurance of uncompromised quality and consistency. Larger batches reduce variations, maintain homogeneity, and deliver a stable brewing process. This not only keeps your customers satisfied but also ensures your brewery's reputation for excellence remains untarnished. With our fermenter, you're not just brewing beer; you're crafting an exceptional and unwavering experience for your customers, batch after batch.

3. Operational Efficiency

Streamlining your brewing process is crucial for efficiency and cost-effectiveness. Fewer fermenters mean less labor, reduced cleaning and maintenance time, and a more optimized production process. The result? A more efficient and profitable brewery.

Operational efficiency is the heartbeat of any successful brewery. A streamlined brewing process not only reduces costs but also enhances productivity, allowing you to meet demand while maintaining high-quality standards. Our 20,000L beer fermenter is the cornerstone of operational efficiency in the world of brewing, and here's how it can transform your brewery:

Fewer Fermenters, Greater Efficiency

The key to operational efficiency with our 20,000L fermenter lies in the principle of consolidation. By replacing multiple smaller fermenters with a single, large-capacity vessel, you eliminate the complexities associated with managing numerous individual batches. This consolidation leads to a myriad of benefits:

1. Labor Savings: Handling and monitoring multiple small fermenters can be labor-intensive. With our 20,000L fermenter, you significantly reduce the number of vessels to manage, which in turn reduces labor requirements. Fewer hands on deck means cost savings and a more efficient workforce allocation.

2. Time Optimization: Cleaning, sterilizing, and maintaining smaller fermenters can be time-consuming. Our larger fermenter requires less frequent cleaning cycles, as there are fewer vessels to manage. This translates to more brewing time and less downtime, thereby maximizing production capacity.

3. Resource Efficiency: Smaller fermenters can lead to excessive consumption of resources such as water, energy, and cleaning agents. The 20,000L fermenter offers resource efficiency through reduced usage. This not only minimizes your environmental footprint but also decreases operational costs.

4. Workflow Optimization: Managing a single, large fermenter streamlines your brewing process. It eliminates the complexities associated with coordinating and monitoring multiple fermenters simultaneously. This optimization leads to fewer errors, a smoother workflow, and ultimately, a more efficient and profitable brewery.

Enhanced Quality Control

Efficiency isn't just about cost savings; it's also about maintaining quality. Our 20,000L fermenter provides better control over the brewing process, leading to a consistent and high-quality end product. With fewer variables to manage, the risk of human error is reduced, and the production process becomes more standardized.

Competitive Advantage

In a competitive brewing industry, operational efficiency can be a significant differentiator. The ability to meet demand, maintain quality, and reduce costs is a winning combination. This not only keeps your existing customers satisfied but also helps you attract new ones, driving growth and profitability.

Our 20,000L beer fermenter is your gateway to operational efficiency, cost savings, and enhanced production capacity. It consolidates your brewing process, reducing labor, optimizing time, conserving resources, and enhancing quality control. In a dynamic and highly competitive industry, operational efficiency is key to your brewery's success. With our fermenter, you're not just brewing beer; you're brewing excellence. Elevate your brewery's operations, reduce costs, and gain a competitive edge with our 20,000L beer fermenter.

4. Space Utilization

Our 20,000L fermenter minimizes the floor space required for your brewery equipment. This space-saving design allows you to make the most of your available area, either for other essential brewery components or simply for a more organized and efficient layout.

Space is a valuable asset in any brewery. Efficient space utilization can be the key to unlocking productivity, enhancing workflow, and accommodating the expanding needs of your operation. Our 20,000L beer fermenter is designed with a space-saving approach, allowing you to make the most of your available area for a more organized, efficient, and productive brewery layout.

Maximizing Space Efficiency

Here's how our 20,000L fermenter optimizes space utilization:

Streamlined Footprint: Traditional brewing setups often require multiple smaller fermenters, which can consume considerable floor space. Our larger fermenter consolidates production into a more compact area, leaving ample room for other brewery components. This streamlined footprint means you can create a more organized and efficient workspace.

Efficient Flow: The space-saving design of our 20,000L fermenter allows for a more logical and efficient flow of materials and personnel within your brewery. With fewer fermenters to navigate, movement becomes less cluttered, reducing the risk of accidents and improving overall operational safety.

Resource Consolidation: The efficient use of space extends beyond just floor area. Our fermenter minimizes the need for extra storage, cleaning, and maintenance space typically required for numerous smaller vessels. This means you can make better use of your square footage, focusing on what truly matters for your brewing process.

Equipment Placement: With more space available, you have greater flexibility in placing other essential brewery equipment, such as milling machines, bottling lines, or storage tanks. This freedom in equipment placement can lead to an even more efficient and optimized brewery layout.

Organized and Efficient Layout

The benefits of space optimization go beyond mere aesthetics. An organized and efficient brewery layout can have a significant impact on your daily operations:

Enhanced Productivity: An organized layout reduces the time and effort required to move from one task to another, which, in turn, improves overall productivity. This efficiency can lead to higher production capacity and quicker order fulfillment.

Safety and Quality Control: With an uncluttered and well-organized workspace, you create an environment where safety and quality control measures can be more effectively enforced. This leads to a safer workplace and higher-quality product.

Room for Expansion: The efficient use of space leaves room for future expansion. As your brewery grows, you won't be limited by space constraints. Our 20,000L fermenter, with its compact footprint, ensures you're prepared for future success.

A Competitive Edge

In a competitive brewing industry, every advantage counts. An optimized brewery layout can streamline operations, reduce costs, and enhance your ability to meet market demands. It's not just about brewing beer; it's about doing it in a way that maximizes efficiency and productivity.

Our 20,000L beer fermenter is more than just a vessel; it's a space-saving solution that transforms your brewery's layout, paving the way for enhanced productivity and success. With a streamlined footprint, you can make the most of your available space, leading to a more efficient, organized, and competitive brewery. Elevate your brewing game with our 20,000L beer fermenter, and watch your brewery's efficiency and profitability soar.

5. Sustainability

Operating a smaller number of fermenters contributes to a more sustainable brewing process. You'll use fewer resources, including energy, water, and cleaning supplies, making a positive impact on the environment. This commitment to sustainability can resonate with eco-conscious consumers and give your brewery a competitive edge.

Sustainability has become a defining factor in today's brewing industry. Breweries that prioritize environmentally responsible practices not only reduce their ecological footprint but also appeal to eco-conscious consumers. Our 20,000L beer fermenter aligns perfectly with this sustainable ethos, offering numerous eco-friendly advantages that can revolutionize your brewery while making a positive impact on the environment.

Resource Conservation: An Eco-Friendly Approach

One of the key features that sets our 20,000L fermenter apart is its ability to minimize resource usage:

Reduced Energy Consumption: Operating multiple smaller fermenters often demands more energy due to additional cooling and heating requirements. Our single, large fermenter offers better thermal stability, using less energy to maintain optimal fermentation conditions. This translates into significant energy savings and a reduced carbon footprint.

Water Efficiency: Smaller fermenters may require frequent cleaning and sterilization, which can lead to a higher water consumption. Our 20,000L fermenter's consolidated design means fewer vessels to clean, resulting in reduced water usage. This eco-conscious approach not only conserves water but also lowers operational costs.

Sustainable Cleaning Practices: Fewer fermenters mean fewer cleaning cycles and less usage of cleaning supplies, such as chemicals and detergents. This not only reduces chemical waste but also contributes to a cleaner and more sustainable brewery environment.

Eco-Friendly Manufacturing

Our commitment to sustainability goes beyond just the operational advantages of our 20,000L fermenter. The manufacturing process of our product itself is designed with eco-friendliness in mind:

Material Efficiency: Our fermenter is constructed with durable and long-lasting materials, minimizing the need for frequent replacements and reducing waste.

Recyclable Components: We use components that are easy to recycle at the end of their lifecycle, contributing to a circular economy.

Reduced Emissions: By consolidating production into one large fermenter, we lower the carbon emissions associated with manufacturing multiple smaller vessels.

Competitive Edge through Sustainability

In today's market, consumers are increasingly conscious of environmental issues, and they are actively seeking out sustainable products. By investing in our 20,000L beer fermenter and adopting sustainable brewing practices, your brewery can gain a competitive edge:

Eco-Conscious Consumer Appeal: A commitment to sustainability resonates with eco-conscious consumers. It can attract a loyal customer base that values environmentally responsible businesses, giving your brewery an edge in a crowded market.

Brand Reputation: Breweries that prioritize sustainability often build strong, positive brand reputations. This reputation can lead to greater brand loyalty and advocacy among your customers.

Cost Savings: Sustainability practices frequently lead to cost savings. By using fewer resources, you can lower operational expenses and enhance profitability.

Our 20,000L beer fermenter is not just a brewing vessel; it's a step towards a greener, more sustainable brewing industry. With reduced resource consumption, eco-friendly manufacturing, and a focus on environmental responsibility, our product aligns with the values of modern consumers and offers a competitive advantage. By brewing with a green heart, you're not only creating exceptional beer but also making a positive impact on the planet and the future of your brewery.

6. Advanced Fermentation Control

Our fermenter comes equipped with state-of-the-art temperature and pressure control systems, ensuring precise and consistent fermentation management. This advanced control leads to higher-quality brews and greater consumer satisfaction.

In the world of brewing, the journey from raw ingredients to the perfect pint is an intricate dance of time, temperature, and pressure. Advanced fermentation control is the linchpin of this process, and our 20,000L beer fermenter is your symphony conductor. With state-of-the-art temperature and pressure control systems, it empowers you to create brews of impeccable quality, ensuring unwavering consumer satisfaction.

Precision Temperature Control

Optimal Yeast Activity: Yeast, the magical microorganism responsible for fermentation, is highly temperature-sensitive. Our fermenter's advanced temperature control system allows you to set and maintain precise temperature profiles during the fermentation process. This ensures that the yeast operates optimally, producing the desired flavor and alcohol content for your beer.

Consistency Across Batches: Fluctuations in fermentation temperature can lead to variations in flavor and aroma, which compromise the consistency of your brews. With our temperature control system, you can maintain a consistent and controlled environment, ensuring that each batch is a true reflection of your brew's intended characteristics.

Achieving Unique Styles: Different beer styles require different fermentation temperatures. Our advanced control system gives you the flexibility to create various beer styles with confidence, whether it's a crisp lager or a rich stout. You can experiment with various yeast strains and recipes, knowing that the temperature control will support your creative journey.

Pressure Management for Quality Assurance

Carbonation Control: Precise pressure control is essential for achieving the perfect level of carbonation in your beer. With our fermenter, you can easily manipulate and maintain the pressure levels necessary for the style you're brewing, from effervescent IPAs to lightly carbonated pilsners.

Reduced Risk of Off-Flavors: Incorrect pressure levels can lead to off-flavors, such as over-carbonation or the presence of undesirable compounds. Our fermenter's pressure control system helps you minimize these risks, ensuring your beer maintains a clean and consistent taste.

Product Stability: Consistent pressure control isn't just about taste; it also influences product stability. It can prevent issues like over-foaming or bottle explosions, safeguarding the quality of your beer and the safety of your customers.

Consumer Satisfaction and Brand Loyalty

The value of advanced fermentation control extends beyond the brewing process. It directly influences consumer satisfaction and brand loyalty:

Higher Quality Brews: Precise fermentation control results in higher-quality brews that consistently meet consumer expectations. This level of quality can lead to positive word-of-mouth and repeat business.

Reliable Brand Reputation: Breweries known for producing high-quality, consistent beer build strong, reliable brand reputations. This reputation not only attracts more customers but also retains them.

Exploration and Innovation: With the assurance of advanced fermentation control, you have the freedom to explore new beer styles and innovate, which can further capture the interest of consumers seeking unique and exciting flavors.

Our 20,000L beer fermenter isn't just a vessel; it's the embodiment of brewing excellence. The advanced temperature and pressure control systems ensure that each batch you produce is a masterpiece of precision and quality. With unwavering consumer satisfaction, you're not just brewing beer; you're crafting an experience that keeps your customers coming back for more. Elevate your brewing to an art form with our 20,000L beer fermenter, where precision meets perfection, and satisfaction is guaranteed.

7. Reduced Risk of Contamination

Minimizing the number of entry points and connections reduces the risk of contamination, safeguarding your product's integrity and your brewery's reputation.

Maintaining the purity and integrity of your brew is paramount to any successful brewery. The risk of contamination, however, is an ever-present concern in the brewing industry. Our 20,000L beer fermenter is not just a vessel; it's a fortress of protection, minimizing contamination risks and preserving the quality of your product, along with your brewery's esteemed reputation.

Fewer Entry Points, Less Risk

Contamination can occur through various avenues, including connections, entry points, and equipment interfaces. Here's how our 20,000L fermenter minimizes these risks:

Consolidated Brewing: Traditional brewing setups often involve multiple smaller fermenters, each with its own set of entry points, valves, and connections. This complexity increases the likelihood of contamination, as there are more potential sources of error.

Streamlined Design: Our 20,000L fermenter boasts a consolidated design, significantly reducing the number of entry points and connections. This streamlined design lowers the risk of contamination, as there are fewer opportunities for microorganisms or contaminants to infiltrate your brew.

Improved Hygiene: Maintaining a single, large fermenter is inherently more straightforward in terms of cleaning and sterilization. The reduced number of vessels to manage results in more efficient and thorough cleaning, contributing to a higher level of hygiene and reducing the chances of contamination.

Enhanced Quality Control

Minimizing the risk of contamination is not only about protecting your product but also about ensuring the quality and consistency that your customers expect. Our 20,000L fermenter empowers you with the following quality control advantages:

Consistent Taste and Aroma: Contaminants can introduce off-flavors and aromas, affecting the taste and overall experience of your beer. With our fermenter's reduced contamination risk, you can maintain the desired taste and aroma characteristics batch after batch.

Reliable Product Integrity: A reputation for quality and integrity is the lifeblood of any brewery. Our fermenter helps protect your product's integrity, safeguarding your brewery's reputation and ensuring customer trust.

Protecting Brand Reputation

In the competitive brewing industry, reputation is everything. A single incident of contamination can tarnish your brand's image and lead to financial losses. Our 20,000L beer fermenter acts as a guardian, ensuring that your beer remains pure and your reputation remains untarnished:

Brand Loyalty: Breweries with a track record of producing uncontaminated, high-quality beer build strong brand loyalty. Satisfied customers become loyal patrons and advocates for your brewery.

Consumer Trust: Trust is the foundation of any successful brand. When consumers trust your product's quality and purity, you build long-lasting relationships and earn customer recommendations.

Risk Mitigation: Contamination incidents can result in recalls and legal issues. Our fermenter minimizes these risks, ensuring smooth operations and reducing the potential for costly setbacks.

Our 20,000L beer fermenter is more than a brewing vessel; it's a shield of protection for your brew and your brand. By reducing contamination risks, it safeguards the integrity of your product and your brewery's reputation. With our fermenter, you're not just brewing beer; you're ensuring that every sip is a testament to purity and quality, a true reflection of your dedication to brewing excellence. Guard your brew and your brand with our 20,000L beer fermenter, where contamination is a concern of the past, and trust is the currency of the future.

8. Economies of Scale

Larger batch production often results in cost savings due to economies of scale. Whether it's purchasing raw materials or optimizing labor costs, our 20,000L fermenter can enhance your brewery's profitability.

In the dynamic and competitive world of brewing, achieving economies of scale is a pivotal strategy to enhance profitability. Our 20,000L beer fermenter is not just a brewing vessel; it's a catalyst for cost savings and revenue growth. Here's how it can help your brewery realize the benefits of larger batch production and drive profitability.

Cost Savings through Larger Batches

Efficient Raw Material Utilization: Brewing on a larger scale allows you to optimize the use of raw materials. Whether it's malt, hops, or other ingredients, purchasing in bulk quantities often comes with cost savings. The 20,000L fermenter's capacity enables you to make the most of these economies of scale, reducing your material costs per batch.

Labor Efficiency: A single, larger fermenter requires less labor to manage than multiple smaller ones. Fewer vessels mean fewer hands needed for operation, cleaning, and monitoring. This labor efficiency leads to cost savings in your brewery's workforce expenses.

Reduced Equipment Costs: Smaller fermenters, due to their numbers, may require a more extensive setup of pumps, hoses, and other equipment. Our 20,000L fermenter's consolidated design simplifies this setup and reduces the need for additional equipment, lowering your capital expenditure.

Streamlined Operations

Lower Maintenance Costs: Maintaining and cleaning fewer fermenters reduces maintenance expenses. With fewer vessels to monitor, your maintenance team can allocate their time more efficiently, addressing issues promptly and reducing downtimes.

Reduced Cleaning and Sterilization Expenses: Smaller fermenters often require more frequent cleaning and sterilization cycles. With our larger fermenter, you save on cleaning supplies, energy, and water usage.

Increased Output, Higher Profit Margins

Higher Production Capacity: Larger batch production enables you to meet higher demand levels. It's not just about saving costs; it's about capitalizing on the opportunity to brew more beer and capture a larger market share.

Consistent Quality at Scale: Our 20,000L fermenter ensures that as you scale up, you don't compromise on quality. With consistent quality, you can maintain consumer satisfaction and build brand loyalty, allowing you to command premium prices for your beer.

Market Competitiveness: With the ability to produce more beer at a lower cost per unit, you can remain competitive in the market. It's not just about profitability but also about staying relevant and appealing to consumers.

Strategic Growth and Investment

Future-Proofing: As your brewery grows, you can rely on our 20,000L fermenter to support your expansion plans. It provides the capacity you need to meet increasing demand and the agility to explore new markets and brew diverse beer styles.

Enhanced Profitability: The economies of scale generated by our fermenter can significantly boost your profitability. These savings can be reinvested into your business, whether it's expanding your product line, improving your brewery facilities, or embarking on marketing and promotional activities.

Our 20,000L beer fermenter isn't just a brewing vessel; it's a catalyst for success. By leveraging economies of scale, you can reduce costs, enhance profitability, and remain competitive in the brewing industry. With its capacity for larger batch production, this fermenter is more than just a tool; it's a cornerstone for sustainable growth, enhanced efficiency, and greater profitability. Brew with confidence and seize the advantages of scale with our 20,000L beer fermenter.

Conclusion

In conclusion, our 20,000L beer fermenter is the perfect investment for commercial brewery plants looking to maximize efficiency, quality, and scalability. By choosing our product, you are taking a significant step toward success in the competitive brewing industry. Elevate your brewing game with our top-of-the-line fermenter, and experience the benefits of increased production capacity, consistency, and cost-effectiveness. Don't miss out on this opportunity to revolutionize your brewery and leave your mark in the world of brewing excellence. Contact us today to take your brewery to the next level!

FAQ

1. What is a 20,000L beer fermenter, and how does it work?

A 20,000L beer fermenter is a large vessel used in breweries to ferment and condition beer. It's where yeast transforms sugars into alcohol and carbon dioxide, producing the final alcoholic beverage. Our fermenter is equipped with advanced temperature and pressure control systems to ensure precise and consistent fermentation management.

2. What are the benefits of using a 20,000L beer fermenter in my brewery?

The benefits of using a 20,000L beer fermenter are numerous, including increased production capacity, quality consistency, operational efficiency, space optimization, sustainability, advanced fermentation control, reduced risk of contamination, and the cost-saving advantages of economies of scale.

3. Can I use a 20,000L fermenter for different types of beer?

Yes, our 20,000L fermenter is versatile and can be used for brewing various styles of beer. The advanced temperature and pressure control systems allow you to create different beer styles with precision.

4. How does this fermenter contribute to sustainability in brewing?

Our 20,000L beer fermenter minimizes resource consumption, including energy, water, and cleaning supplies, reducing the environmental impact of brewing. This commitment to sustainability can resonate with eco-conscious consumers and enhance your brewery's reputation.

5. How does the fermenter reduce the risk of contamination?

The consolidated design of the 20,000L fermenter reduces the number of entry points and connections, minimizing opportunities for contaminants to enter the brewing process. This design helps safeguard your product's integrity and your brewery's reputation.

6. What are the cost-saving advantages of using a 20,000L fermenter?

Larger batch production often results in cost savings due to economies of scale. Our 20,000L fermenter allows you to purchase raw materials in bulk, optimize labor costs, reduce maintenance expenses, and minimize cleaning and sterilization costs.

7. How can I purchase a 20,000L beer fermenter for my brewery?

You can contact our sales team to inquire about purchasing a 20,000L beer fermenter for your brewery. We'll provide you with all the necessary details, including pricing, customization options, and delivery information.

8. Can the 20,000L beer fermenter be integrated into my existing brewery setup?

Our fermenter can be customized to fit into your existing brewery layout. Our team can work with you to ensure a seamless integration that maximizes efficiency and space utilization.

9. What maintenance is required for the 20,000L fermenter, and do you offer support?

Regular cleaning and maintenance are essential for optimal performance. We provide maintenance guidelines and can offer support to ensure your fermenter operates at its best. Our team is available for any technical assistance you may need.

10. Can I upgrade or expand my brewing capacity with this fermenter in the future?

Yes, our 20,000L beer fermenter is a future-proof investment. As your brewery grows, you can rely on this fermenter to support your expansion plans and increased demand.