Automatic solution filling equipment is a kind of machine equipment for automatic canning of liquid solutions. It usually consists of a solution tank, an automatic filling machine, a piping system and an automatic control system. The equipment can automatically complete the process of canning liquid solutions, thereby increasing production efficiency, reducing production costs and improving product quality.

Automatic solution filling equipment typically uses metering pumps or weight sensors to precisely measure the amount of liquid and fill it into the tank. At the same time, it can also control the flow and speed of the liquid to ensure the stability and consistency of the filling process. Some automatic solution canning equipment can also help to clean equipment such as tanks, pipes and pumps by adding an automatic cleaning function to improve hygiene standards and production efficiency.

Today we mainly introduce the automatic solution canning equipment used for canning beer.

Classification of liquid filling machinery

Liquid filling machines can be divided into normal pressure filling machines, pressure filling machines and vacuum filling machines according to the filling principle.

1. Normal pressure filling machine

It is filled under atmospheric pressure by the weight of the liquid. This type of filling machine is divided into two types: timing filling and constant volume filling, which are only suitable for filling low-viscosity and gas-free liquids such as milk and wine.

2. Pressure filling machine

It is filled at a pressure higher than atmospheric pressure, which can also be divided into two types: one is that the pressure in the liquid storage tank is equal to the pressure in the bottle, and it is filled by the liquid's own weight flowing into the bottle, which is called equal pressure filling. The other is that the pressure in the liquid storage tank is higher than the pressure in the bottle, and the liquid flows into the bottle by the pressure difference. This method is often used in high-speed production lines. The pressure filling machine is suitable for filling gas-containing liquids, such as beer, soda, champagne, etc.

3. Vacuum filling machine

Filling is performed at a pressure in the bottle below atmospheric pressure. This liquid filling machine has a simple structure, high efficiency, and a wide range of adaptability to the viscosity of materials, such as oil, syrup, fruit wine, etc.

Solution filling equipment for beer

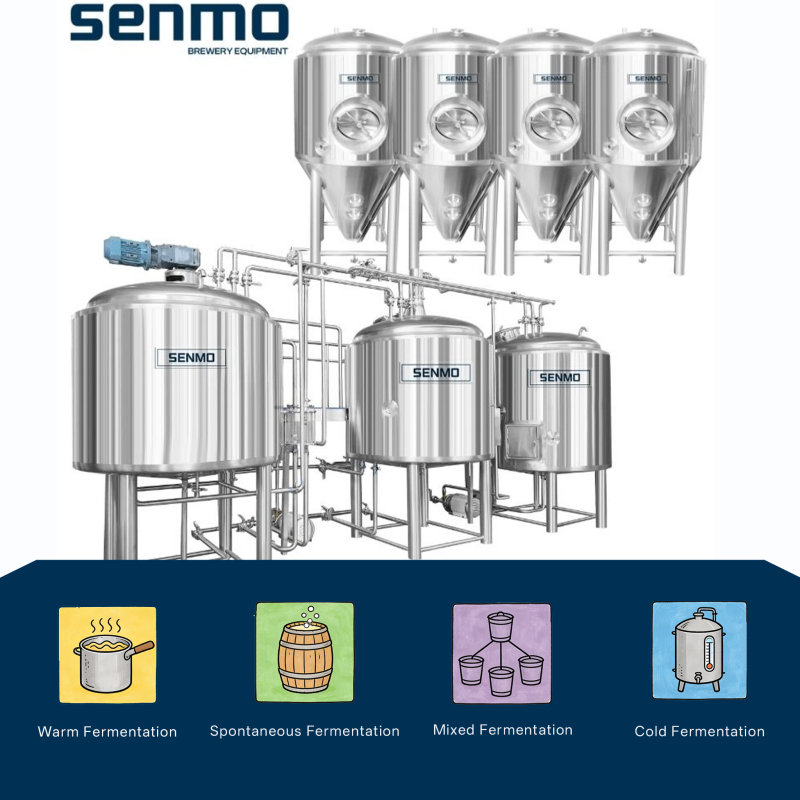

Automatic solution canning equipment can be used for beer canning. In the beer production process, automatic solution canning equipment is usually used in conjunction with other equipment, such as beer fermentation tanks, filters, beer filling machines, etc., to complete the beer production process.

In beer production, the function of automatic solution canning equipment is to mix the beer raw materials of different formulas according to the precise ratio and add them to the fermentation tank. Machine fills beer into tanks.

In the process of beer canning, automatic solution canning equipment needs to take into account the bubbles and foam of beer to ensure that the quality and taste of beer after canning meet the requirements. Therefore, the automatic solution canning equipment in the beer production process needs to have the characteristics of high precision, high efficiency, reliability and stability, so as to ensure the quality and quantity of beer production can be guaranteed.

In addition, in the beer canning process, the automatic solution canning equipment also needs to take into account hygiene and safety issues. Beer is a kind of food that is easily contaminated. Therefore, when using automatic solution canning equipment, it is necessary to strictly abide by hygienic standards, and regularly clean and disinfect the equipment.

For different types of beer, automatic solution canning equipment also needs to be adjusted according to different recipes. For example, the formula and production process of light-colored beer and dark-colored beer are different, so it is necessary to adjust and set up equipment for different beer types to ensure that the quality and taste of beer can meet the requirements.

Automated Control and Data Monitoring

In addition, the automatic solution filling equipment can also realize the automatic control and data monitoring of the production process. Through networking with computers and other equipment, remote monitoring and control can be realized, and real-time monitoring and adjustment of the production process can be carried out. At the same time, the automatic solution canning equipment can also record various data in the production process, such as liquid flow, temperature, pressure and other information, as well as equipment operating status and fault information, to facilitate data analysis and optimization of the production process.

For beer manufacturers, the introduction of automatic solution canning equipment can improve production efficiency, reduce production costs, reduce the difficulty and risk of manual operation, and improve the quality and consistency of beer production. In addition, automatic solution canning equipment can also meet the production needs of different scales and outputs, and is suitable for different types of enterprises such as large beer manufacturers and small craft beer manufacturers.

In general, the application of automatic solution canning equipment in the beer production process has a wide range of significance. It provides a more efficient, more accurate and more reliable production plan for beer production, bringing better production efficiency and quality Assure. As a professional beer equipment manufacturer, automatic beer canning equipment is one of our main products. If you are planning to purchase beer canning equipment, we can be your professional supplier.

FAQ

Q1: What is automatic pressure solution filling equipment for beer?

Automatic pressure solution filling equipment for beer is specialized machinery designed to automate the process of filling beer into bottles under controlled pressure conditions. It ensures accurate and consistent filling while minimizing oxygen exposure, which can impact beer quality.

Q2: How does automatic pressure solution filling equipment work?

In this type of equipment, bottles are placed on a conveyor, and the filling process is initiated. The equipment purges the bottles with CO2 to remove any oxygen, then fills them with beer under precise pressure levels to prevent over-foaming. The filled bottles are then capped, ensuring minimal oxygen pickup during the process.

Q3: What are the benefits of using automatic pressure solution filling equipment?

Automatic pressure solution filling equipment offers numerous benefits, including precise and consistent filling levels, reduced oxygen exposure, improved shelf stability, increased production speed, and enhanced overall product quality.

Q4: Is this equipment suitable for small to medium-sized breweries?

Yes, automatic pressure solution filling equipment is suitable for breweries of various sizes, including small and medium-sized operations. It can offer significant advantages by reducing labor and increasing efficiency without requiring the extensive space and investment of large-scale automated systems.

Q5: Can this equipment handle different bottle sizes and types?

Yes, most automatic pressure solution filling equipment can be adjusted to accommodate different bottle sizes and types commonly used in the brewing industry. This flexibility allows you to package a variety of products.

Q6: How fast can this equipment operate?

The speed of operation varies depending on the specific model and the complexity of your brewery's workflow. Generally, these machines can significantly increase throughput compared to manual or semi-automatic filling methods.

Q7: What maintenance is required for automatic pressure solution filling equipment?

Regular maintenance is essential to keep the equipment in optimal working condition. This includes cleaning and sanitizing the machine, checking for wear and tear, and addressing any technical issues promptly to avoid disruptions.

Q8: Can this equipment integrate with other brewery systems?

Yes, automatic pressure solution filling equipment can integrate with other brewery systems, such as conveyors, bottle rinsers, labelers, and quality control devices. Integrating these systems can create a seamless bottling process.

Q9: What safety measures should be considered when using this equipment?

Safety is a top priority when using any machinery. Ensure that your staff is trained in the proper operation of the equipment and provide appropriate protective gear. Regularly inspect the machine for potential hazards and adhere to manufacturer guidelines.

Q10: How can I choose the right automatic pressure solution filling equipment for my brewery?

When selecting automatic pressure solution filling equipment, consider factors such as your brewery's production capacity, bottle sizes, desired automation level, available space, and budget.