Entire 500L beer equipment for microbrewery and restaurant

In the world of craft beer, innovation and quality reign supreme. As microbreweries and restaurants seek to stand out in a competitive market, the choice of beer equipment becomes pivotal. Enter the Entire 500L Beer Equipment, a cutting-edge solution designed to elevate your brewing game and deliver exceptional brews that keep your patrons coming back for more.

Craftsmanship Meets Technology

At the heart of every great brew is the brewing system, and the Entire 500L Beer Equipment is the pinnacle of craftsmanship and technology. This state-of-the-art system seamlessly combines the artistry of traditional brewing methods with the precision of modern engineering, making it the perfect choice for microbreweries and restaurants dedicated to delivering excellence in every pint.

1. Crushing system in the entire 500L microbrewery beer equipment:

The malt crushing process should be completed within 30 minutes as soon as possible,

According to the capacity of brewhouse system is 500L, the required amount of malt is 100KG per month

Therefore, the malt crusher selects the 200-300Kg/h double-roller crusher

2.The brewhouse 500L

Mash tun adopts the efficient dimple plate jacket heat exchange technology and the scientific steam turbulence principle to achieve the maximum heat conduction and energy saving effect. At the same time, the fully automatic temperature control technology is adopted to ensure the accuracy of the heating rate and the holding time at each stage of the saccharification process. The internationally advanced suspension speed control system is adopted, and the frequency conversion and automatic mixing mode are adopted to ensure the uniform mixing of mash in the saccharification process, which can maximize the best biological activity and conversion and catalytic effect of various enzymes in the saccharification process, thus ensuring the best quality and maximum yield of beer at the source.

The application of advanced internal boiling and pressurization technology can improve the boiling intensity, greatly increase the evaporation effect of dimethyl sulfur, promote the polymerization of protein and other condensable substances, and realize the rapid separation of boiled wort and polymer. The extracorporeal circulation mixing technology is adopted to accelerate the heating rate of wort at the initial stage of boiling, so that the wort will always keep the temperature uniform and consistent during the heating process, and prevent the denaturation of regional wort soluble substances caused by local overheating, thus ensuring the boiling quality of wort

The lauter tun of the entire 500L beer equipment adopts the advanced and scientific special-shaped plow construction system, which ensures that the tank is turned evenly and discharged smoothly, and also improves the filtration speed and production efficiency, and maintains the good transparency and juice yield of wort. The internationally advanced suspension and mixing device, combined with frequency conversion, speed regulation and automatic control technology, makes the operation more convenient and flexible, and the maintenance is simple and the cost is saved. The differential pressure natural filtration can effectively avoid the problems of cloudy wort, tight grains and caking caused by suction filtration (polyurethane thermal foam has the function of rapid suction filtration). The rotary sedimentation tank is designed according to the storage volume of wheat grains on the best unit filter area, which enlarges the diameter to height ratio of the tank body, reduces the sedimentation speed, promotes the sedimentation and condensation of the coagulates, and achieves the best separation. Equipped with thermal coagulant storage tank, it can improve wort yield and reduce environmental pollution

3. Heating system

Generally, steam generator and electric heating tube are used for heating

The electric heating tubes generally adopts multiple groups of arc heating pipes,Steam generators (electric steam generator, gas steam boiler and gas-fired boiler),also, the direct-fire heating brewhouse also popular in some south america countries such as Argentina, Uruguay, Mexico, Colombia, Chile...

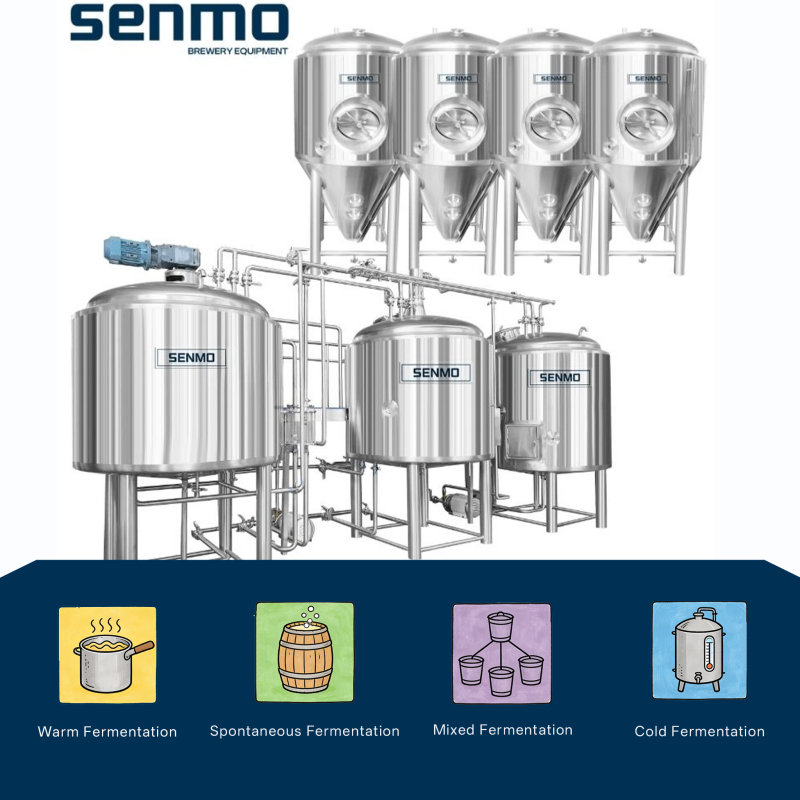

4. Fermentation system and cooling system:

You can chose 500L fermenters or 1000L fermenters for the entire 500L beer equipment,it depends on the beer production capacity,the space area,the investment...

The following fittings are matched with the 500L fermenters:

-Mechanical pressure regulating valve

-Beer sample valve

-Breath valve

-Thermometer

-Hops dosing port

-Temperature sensor

-Beer rotary pipe

-Drain outlet

-CIP ball and CIP arm

-CO2 carbon stone

The connection of the fittings can be tri-clamp,diary couplers and other connection way you want.Meanwhile,if you need other fitings or port on the fermenters,you can tell us and we do the special design for you.

The refrigeration system of entire 500L craft beer equipment mainly includes: wort is cooled to the inoculation temperature through plate heat exchanger. The other is the temperature control of fermentation tank,

Main composition: plate heat exchanger (used for saccharifying wort cooling): 5 m2 heat exchange area is generally used according to 500L wort volume

Refrigerator: generally 5HP

Fill 1000L of ice water. Ice water circulating pump and corresponding pipeline valves

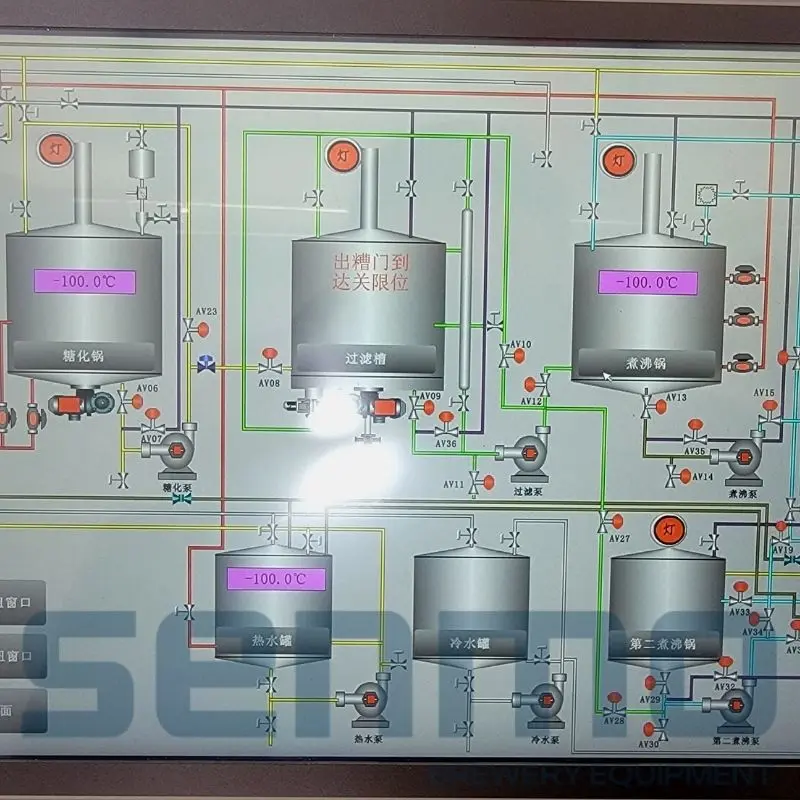

5. Control system of the entire 500L beer equipment

At present, the control system of small beer equipment only adopts PLC control or PID instrument control

The instrument control system cannot realize the temperature rise in stages of mashing, but can only realize the start and stop of the motor and the temperature control of the fermentation tank,

PLC programming control is relatively more high-end, which can control the temperature in several stages, and the control is more intelligent.

If you want an accurate offer of the entire 500L beer equipment for microbrewery and restaurant,you can contact with our sales engineer,he can make an accuracte proposal and send you more details instructions on the equipment,beside of the quote,we can provide you with the following services:

Sales consulting. SENMO provide fast, professional and detailed beer brewery equipment configuration list according to customer requirements.

Brewery technical design. According to the concept of customization, put forward design suggestions, integrate customer requirements, issue beer brewing process flow diagrams,micro brewery floor plans,machinery, electrical and other drawings, draw 3D drawing, and provide one-to-one tracking services.

Brewery equipment processing and manufacturing. Strictly implement the requirements of beer equipment design drawings, follow the IOS9001 quality management system, strictly control the quality of all links, and provide tanks test records of plates, welding, polishing, pressure, etc. for filing.

Brewery plant delivery and installation. The professional brewery project construction team conducts on-site installation, commissioning and training to ensure accurate delivery for use and continuous tracking maintenance.

Key Features

Capacity: The 500L capacity of this brewing system is ideal for those looking to scale up their production without compromising on quality. Whether you're a microbrewery or a restaurant with a passion for craft beer, this system provides the perfect balance between volume and precision.

Versatility: One of the standout features of the Entire 500L Beer Equipment is its versatility. This system accommodates a wide range of beer styles and recipes, allowing brewers to experiment and create unique flavors that set them apart from the competition.

Efficiency: The system's advanced heating and cooling technology ensures a highly efficient brewing process, reducing energy consumption and minimizing the environmental footprint of your operation.

Quality Control: Precise temperature and fermentation control, combined with quality materials and construction, guarantee the consistency and high-quality of your brews, ensuring every batch is as exceptional as the last.

Ease of Use: Designed with user-friendliness in mind, the Entire 500L Beer Equipment comes with an intuitive control interface that simplifies the brewing process, making it accessible even to those new to the craft.

Benefits for Microbreweries and Restaurants

The Entire 500L Beer Equipment offers a myriad of benefits for both microbreweries and restaurants:

Increased Production: With its 500L capacity, you can produce larger quantities of your signature brews to meet growing demand without sacrificing quality.

Enhanced Reputation: Consistently producing high-quality beer can set you apart in the crowded craft beer market, leading to a loyal customer base and enhanced reputation.

Cost Savings: The system's energy efficiency and ease of use can lead to cost savings in the long run, making it a sound investment for your business.

Innovation: The flexibility of the system allows you to experiment with new recipes and flavors, keeping your customers excited about what's on tap.

Improved Consistency: The precision of the Entire 500L Beer Equipment ensures that your beers maintain their distinct character from batch to batch.

Conclusion

The Entire 500L Beer Equipment is not just a brewing system; it's a game-changer for microbreweries and restaurants. It empowers you to brew with precision, consistency, and efficiency, offering you the tools to create unforgettable beer experiences for your patrons. Elevate your craft and set a new standard in the industry with the Entire 500L Beer Equipment – where tradition meets innovation, and excellence is brewed one batch at a time. Cheers to the future of craft beer!

FAQ

1. What is the Entire 500L Beer Equipment, and who is it designed for?

The Entire 500L Beer Equipment is a brewing system designed for both microbreweries and restaurants. It's a 500-liter capacity brewing system that combines craftsmanship and technology to enable establishments to produce high-quality craft beer.

2. What are the key features that make the Entire 500L Beer Equipment stand out?

The key features of this equipment include its 500-liter capacity, versatility to accommodate various beer styles, energy efficiency, precise temperature control, ease of use, and high-quality construction for consistency and quality in your brews.

3. How can the Entire 500L Beer Equipment benefit my microbrewery or restaurant?

This equipment offers increased production capacity, enhanced reputation due to consistent high-quality brews, cost savings through energy efficiency, the ability to innovate with new recipes, and improved batch-to-batch consistency.

4. Is the Entire 500L Beer Equipment suitable for newcomers to brewing?

Yes, it's designed with user-friendliness in mind, making it accessible to both experienced brewers and newcomers to the craft. The intuitive control interface simplifies the brewing process.

5. Can I use the Entire 500L Beer Equipment for different beer styles and recipes?

Absolutely! The system's versatility allows you to create a wide range of beer styles and experiment with various recipes, ensuring you can cater to different customer preferences.

6. What kind of support and maintenance does the Entire 500L Beer Equipment require?

Regular maintenance is essential to keep your equipment in peak condition. We provide guidelines for maintenance, and professional support may be available if needed.

7. Is the Entire 500L Beer Equipment eco-friendly?

Yes, it's designed with energy-efficient technology, reducing energy consumption and minimizing its environmental footprint. This can lead to cost savings and environmental benefits.

8. Can I scale up my production with the Entire 500L Beer Equipment?

Certainly! The 500L capacity is ideal for scaling up your production to meet increasing demand while maintaining the quality of your brews.

9. How does the equipment ensure batch-to-batch consistency?

The Entire 500L Beer Equipment features precise temperature and fermentation control, combined with high-quality materials and construction, which ensure that each batch of beer maintains its distinct character.