In the realm of craft brewing, precision and innovation are paramount. Introducing our Microbrewery 700L Beer Brewing Equipment, meticulously designed to empower brewers with the tools needed to create exceptional beers.

Microbrewery 700L beer brewing equipment description

This is microbrewery 700L beer brewing equipment made by Shandong SENMO Machinery,it is semi-automatic operation with automatic temperature control.The whole 700L brewing system is made of SUS304 plate,all of the brewing vessels are double layers with insulation.The brewery layout drawing is designed as per the client's site,the kettle heating method also can be customized designed,such as steam heating,electric tubes heating,fire directly heating and etc.Below is a brewing list of the 700L microbrewery system:

700L steam heated mash tun

700L lauter tun

700L hot liquid tank with steam tubes heating

Wort pump and hot liquid pump

Fuel steam generator

Operation platform

Wort grant tank

Hops filter tank

Pipes and valves

Control cabinet

700L beer fermenters

Cold water tank

Chiller

CIP unit

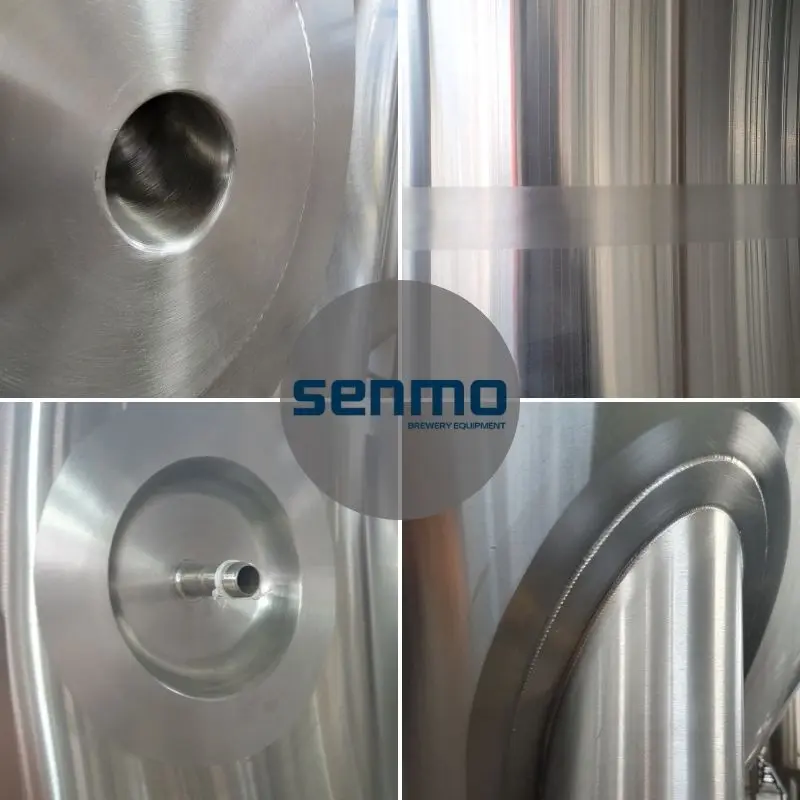

All material of the 700L beer brewing equipment in contact with product will be of Stainless Steel,304.Light glass made of glass,the pipe/Fitting standard will be designed according to your request.All valves in contact with product will be of Hygienic Butter Valve Type .All components and wire will be with CE/UL marked Process connections will be designed according to your request.Sanitary screw couplings or Sanitary Tri-clamp ,welds will be fully burned,shield gas will be used.With no pores,cracks.

The 700L brewing equipment and work will be in compliance with the following norms and standards.

•Machinery Directive 2006/42/EC According to harmonized standard EN ISO 12100:2010

•Low Voltage Directive 2014/35/EU

•Health and Safety requirements of the Directive 2006/42/EC

700L BEER FERMENTERS STANDARD PRODUCT FEATURES

▪SS Dished head

▪Butterfly valves, Sample valve,PVRV

▪Clamps and gaskets, pressure gauge

▪Interior shell: 304 stainless steel, thickness 3mm

▪Exterior shell: 304 stainless steel, thickness 2mm

▪Interior and exterior finish polished to a sanitary finish

▪Interior finish pickled and passivation

▪Dimple jacket cooling jackets

▪Exterior brushed finish

▪Fully welded exterior shell

▪60 degree cone bottom, with an average of 25% head space

▪Rotating racking port

▪Side/Top manway door

▪Dual zone dimple cooling jackets (3 or more on larger tanks)

▪2'' Polyurethane insulation

▪CIP arm and spray ball with a molding technology

▪Sanitary tri-clamp connections

▪Upgrade drain port size

▪Dry hop port

The 700L brewery fittings list as below:

-Wort pump:-Type:3m3/h, 18m-Power:380V 1.5KW-With frequency conversion-Inlet size Ф38, outlet size Ф32-The material connected with wort is sanitary stainless steel 304-With waterproof shield

-Filter pump:-Type:3m3/h, 18m-Power:380V 1.5KW-With frequency conversion-Inlet size Ф38, outlet size Ф32-The material connected with wort is sanitary stainless steel 304-With waterproof shield

-Hot water pump:-Type:3m3/h, 18m-Power:380V 1.5KW-With frequency conversion-Inlet size Ф38, outlet size Ф32-The material connected with wort is sanitary stainless steel 304-With waterproof shield

-Heat exchange plate:-Size:8㎡-Two stage cooling, 6 process;-Cold water inlet G1, cold water outlet Ф32 , wort inlet & outlet Ф32.

-Pipe type hop filter:-Removable-Filter precise:0.1mm

-Brewhouse Pipes:-Size:ISO:Φ38/Φ32-Single welded, double shaped

-Aeration Assembly-With sight glass-Used on wort outlet of the heat exchanger-With thermometer

-Survey Barrel-L=350mm

-Sanchorometer-Size:10°,20°

-Titanium bar-Filter precision: 0.45μm

-Grain-out Rake-L=1500

-Working platform-Punched-hole platform-With stairs and guardrail-Height and size will be designed according to the actual brewhouse size and the brewery place

The above is a brief description of the functions, characteristics and process parameters of microbrewery 700L beer brewing equipment for craft beer. In general, a set of qualified beer equipment should be designed, manufactured and installed according to the characteristics of craft beer, taking into full consideration the adaptation, cleanness, efficiency, oxygen avoidance, energy conservation, safety and other factors of the equipment, so as to meet the needs of craft beer production.

If you are considering entering the brewing beer or craft beer industry. Whether it is investing in bars,breweries, restaurants, or small and medium-sized breweries, it is necessary to have a clear understanding of the requirements for beer brewing technology and equipment technology configuration. If you have any questions, please communicate with professionals and manufacturers in detail. Shandong SENMO Machinery Co., Ltd., as a professional beer equipment provider, provides you with professional technical consultation in the early stage, and carries out equipment design, production, installation, commissioning and other services according to the requirements of beer brewing technology.

FAQ

1. What is the capacity of the Microbrewery 700L Beer Brewing Equipment?

The brewing equipment has a capacity of 700 liters, making it suitable for microbreweries aiming for a versatile and efficient brewing process.

2. Why choose a 700L capacity for a microbrewery?

The 700L capacity strikes a balance between small-batch brewing and meeting demand, providing versatility for brewing a variety of beer styles while maintaining consistent quality.

3. Is the brewing equipment constructed from stainless steel?

Yes, the brewing vessels are crafted from premium 304 stainless steel. This material ensures durability, corrosion resistance, and a hygienic brewing environment.

4. How does the modular design enhance efficiency in brewing operations?

The modular design allows for flexibility in configuring the brewing setup, accommodating different brewing styles and techniques. It enhances efficiency by adapting to the specific needs of the brewmaster.

5. Does the equipment include temperature control features?

Yes, the brewing system is equipped with a precise temperature control system. This feature enables brewers to maintain optimal temperatures during mashing, boiling, and fermentation, ensuring consistency in flavor and quality.

6. What advantages do conical fermentation tanks offer in brewing?

Conical fermentation tanks facilitate efficient yeast settling and fermentation, enhancing the clarity and flavor profile of the beer. This design contributes to a high-quality finished product.

7. How user-friendly is the control panel of the brewing equipment?

The control panel is designed to be user-friendly, featuring intuitive controls and a clear interface. Brewers can easily monitor and adjust parameters, ensuring precise control over each stage of brewing.

8. What is the CIP (Clean-in-Place) system, and how does it streamline the cleaning process?

The CIP system is an automated cleaning system that streamlines the cleaning process. It ensures thorough cleaning of brewing vessels, minimizing downtime between batches and maintaining the highest hygiene standards.

9. Can the brewing equipment accommodate a variety of beer styles?

Yes, the 700L capacity allows for versatility in brewing styles. Whether crafting ales, lagers, or experimental brews, the equipment adapts to the creative vision of the brewmaster.

10. How does the equipment optimize space in a microbrewery?

The compact yet efficient design of the brewing system optimizes space, allowing brewers to make the most of their brewing area without sacrificing production capabilities.

11. Is the brewing equipment time and energy-efficient?

Yes, the efficient heating and boiling system, along with the modular design, contribute to time and energy efficiency. Brewers can focus their efforts on brewing, knowing that the equipment is designed for optimal performance.

12. Can the brewing system be customized for unique brews?

Yes, the modular design and user-friendly controls offer customization options for brewing unique and innovative beers. Brewers have the flexibility to experiment and refine their craft, pushing the boundaries of traditional brewing.

For any additional inquiries, pricing information, or to explore customization options, please contact our sales team. We're here to assist you in integrating the Microbrewery 700L Beer Brewing Equipment into your brewing setup for a seamless and efficient brewing experience. Cheers to brewing excellence!